Foundation pit supporting pile top crown beam structure and construction method thereof

A technology for foundation pit support and pile top, which is applied in foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of high construction cost, waste of manpower and material resources, etc., to ensure the firmness of the structure, save time, The effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

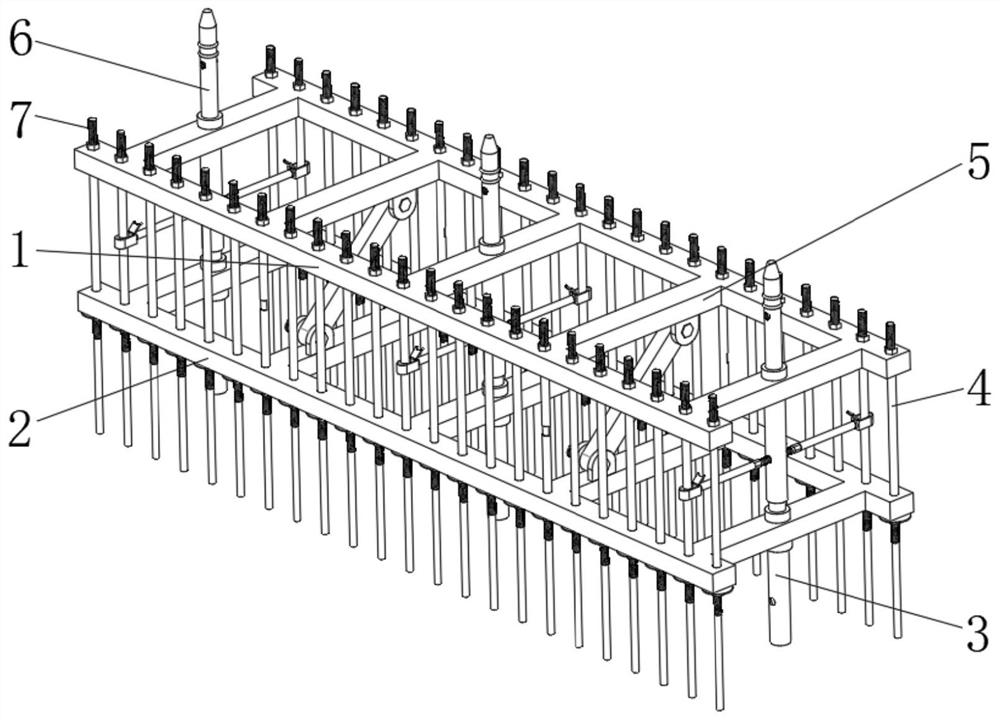

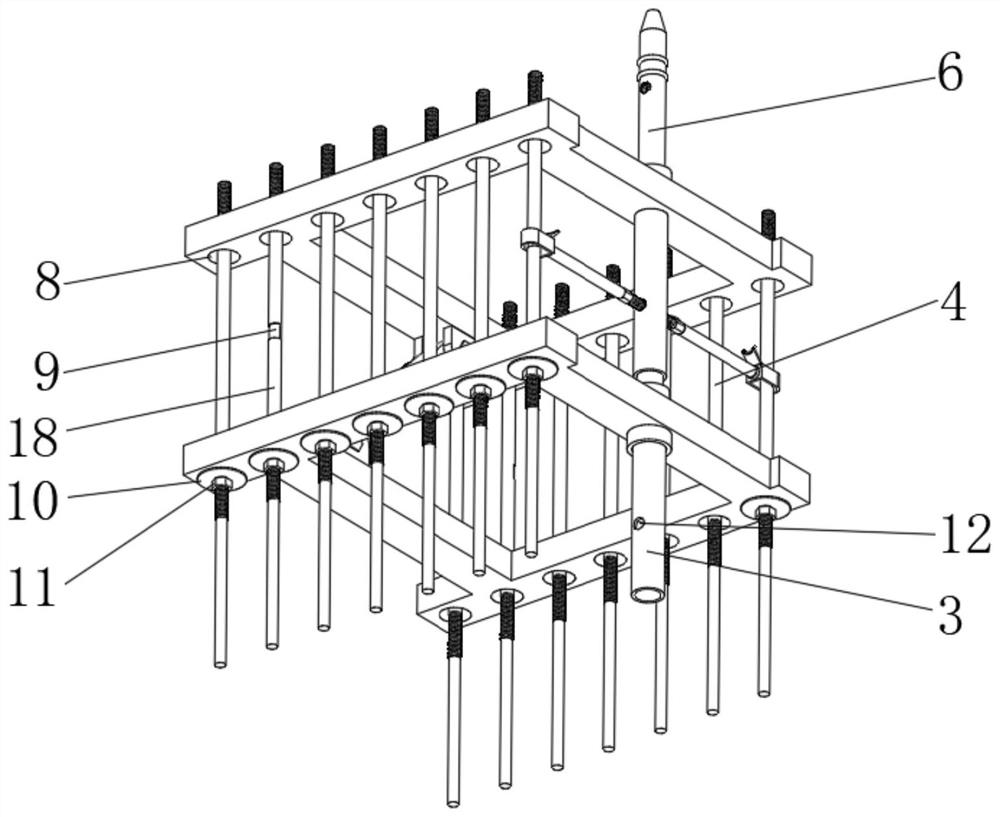

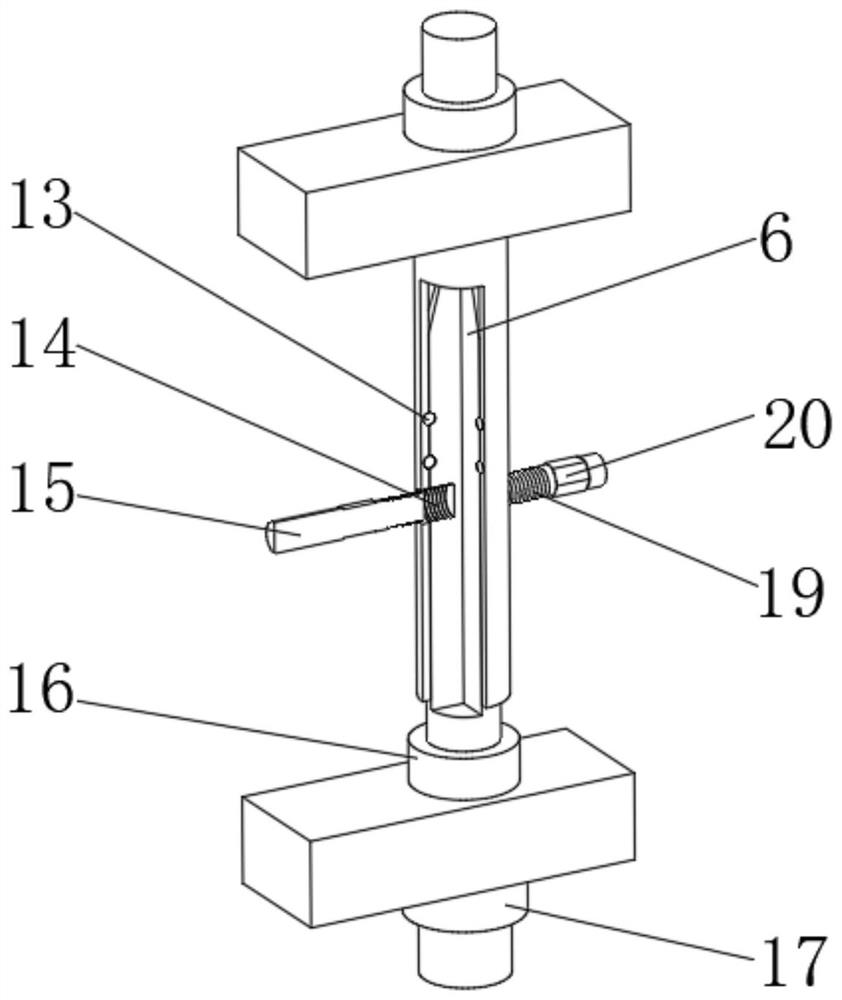

[0045] A foundation pit support pile crown beam structure, such as Figure 1-6 As shown, it includes a first frame body 1 and a second frame body 2, and the first frame body 1 and the second frame body 2 are provided with equidistantly distributed beams 5, and the first frame body 1 and the second frame body The outer wall of the bottom of the frame body 2 is provided with evenly distributed assembly sockets 8, and the first fixed rod 4 and the second fixed rod 18 are respectively inserted in the assembly sockets 8, and the position of the second fixed rod 18 is uniform Corresponding to 5, the bottom of the first fixed rod 4 and the second fixed rod 18 are uniformly provided with a tail rod 33, and a bearing thread 34 is arranged between the tail rod 33 and the first fixed rod 4 and the second fixed rod 18 , the diameter of the tail rod 33 is smaller than the size of the bearing thread 34, the bearing nut 11 is installed on the outer wall of the bearing thread 34, the top of t...

Embodiment 2

[0054] A construction method for foundation pit support pile top crown beam structure, such as Figure 1-6 shown, including the following steps:

[0055] S1: pre-embed the first fixing rod 4 and the second fixing rod 18 with the bearing nut 11 and the ring gasket 10 through the tail rod 33;

[0056] S2: Disassemble and assemble the connecting rod 6 and the connecting sleeve 3 according to the construction requirements;

[0057] S3: Put the second frame body 2 on the first fixed rod 4 and the second fixed rod 18, so that the first fixed rod 4 and the second fixed rod 18 pass through the assembly socket 8 of the second frame body 2;

[0058] S5: Put the socket piece 22 on the second fixing rod 18;

[0059] S4: put the first frame body 1 on the first fixed rod 4 and the second fixed rod 18, so that the first fixed rod 4 and the second fixed rod 18 pass through the assembly socket 8 of the first frame body 1; at the same time The connecting sleeve 3 of the first frame body 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com