Semiconductor equipment precision assembly

A semiconductor and equipment technology, applied in the field of precision components of semiconductor equipment, can solve the problems affecting the service life of precision components of semiconductor equipment, poor cooling effect, damage to semiconductor chips, etc., to improve heat dissipation initiative, ensure stability, and improve safety protection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

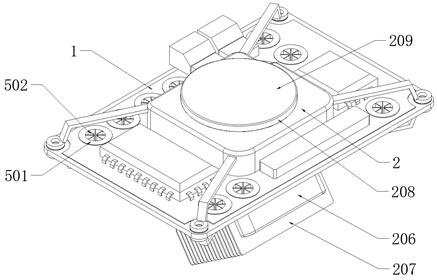

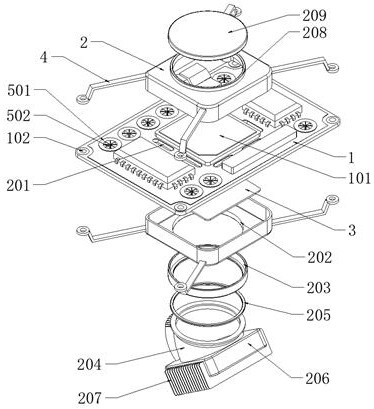

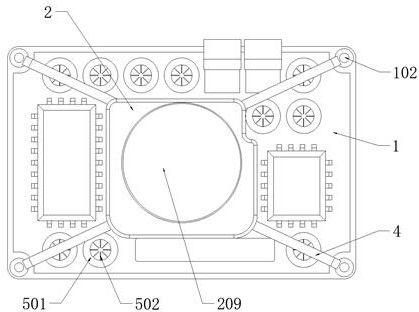

[0046] see Figure 1-10 , a precision assembly of semiconductor equipment, comprising a circuit board 1, a semiconductor chip 101 is fixedly installed at the middle position of the top of the circuit board 1, and a casing 2 sleeved on the outside of the semiconductor chip 101 is fixedly installed at the middle position of the circuit board 1, The inside of the circuit board 1 is provided with a plurality of conduction holes 201 arranged around the semiconductor chip 101, and a connecting screw 202 is fixedly installed on the outer end wall of the bottom of the casing 2, and the outer thread of the connecting screw 202 is connected with a screw thread. Sleeve 203, the interior of threaded sleeve 203 is installed with downwardly extending conduit 204, and the lower end of conduit 204 is fixedly connected with heat exchange box 206, the inside of casing 2 is filled with paraffin and magnetic fluid mixture, the bottom of circuit board 1 is fixedly installed There is a permanent ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com