Davit mounting method for construction of large suspension type steel structure

A technology for the construction and installation of steel structures, which is applied in the processing of building components, building structures, and building materials, etc., can solve the problems of difficulty in adjusting the precision of the suspenders, affect construction, and installation errors, and achieve the guarantee of structural firmness, Reduce construction errors and improve connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

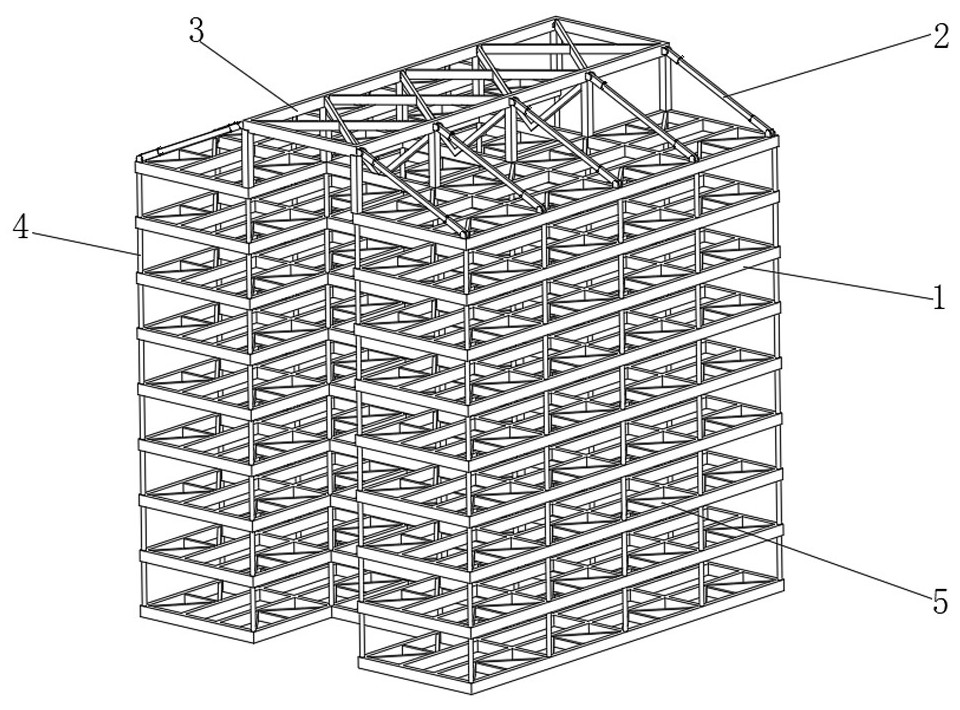

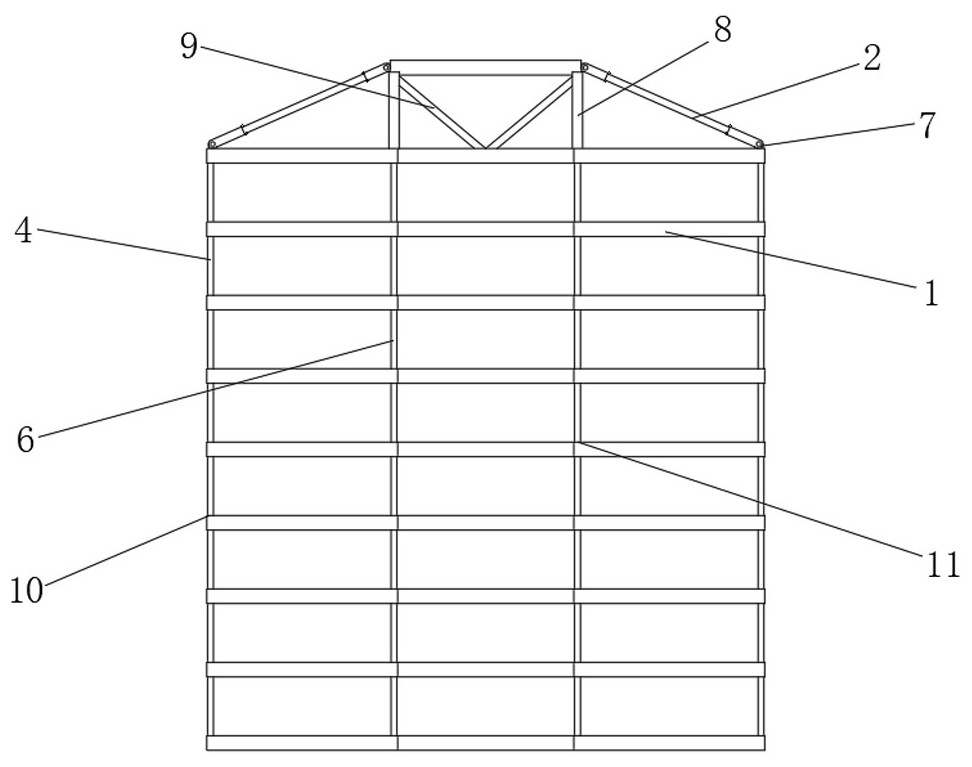

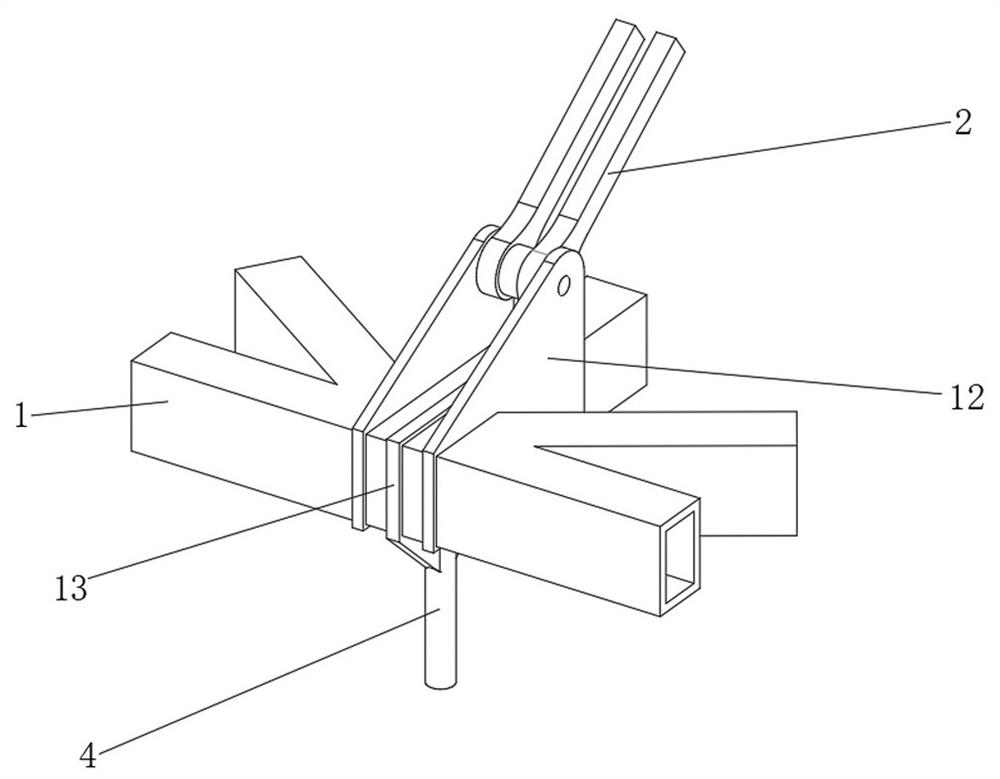

[0052] A method for installing a suspension column for large-scale suspended steel structure construction, such as Figure 1-6 As shown, the above-mentioned hanging columns are divided into three-section installation, and the number of floors where the steel beams on the first floor of the above-ground structure are located is set as X floor, the first section of hanging columns is installed on the X~X+1 floor, and the second section of hanging columns is installed on X +1~X+4 floors, the third section of the suspension column is installed on the X+4~X+6 floor; the first section of the suspension column installation and positioning axis of the X~X+1 floor takes the top hanging point as the reference point; The structure system of the hanging column and the steel beam includes a steel bar truss 1, an inner hanging column main body 6 and an outer hanging column main body 4, and the inner hanging column main body 6 is installed on the inner side of the steel bar truss 1 through an...

Embodiment 2

[0078] A method for installing a suspension column for large-scale suspended steel structure construction, such as Figure 1-6 As shown, in order to improve the reliability of the connection between the two suspenders; this embodiment makes the following improvements on the basis of Embodiment 1: the top outer walls of the outer suspender main body 4 and the inner suspender main body 6 are provided with positioning micro Groove 18, the outer wall of the bottom of the outer hanging column main body 4 and the inner hanging column main body 6 is uniformly provided with positioning protrusions 17, and the positioning protrusions 17 are adapted to the positioning micro-grooves 18; by setting the positioning protrusions 17 and positioning micro-grooves The groove 18 can facilitate auxiliary positioning between the two outer davit main bodies 4 or two inner davit main bodies 6 when connecting and fixing them, thereby improving construction accuracy and reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com