Real-time detection device and method for leakage rate of bottled high-pressure heptafluoropropane fire extinguishing agent

A heptafluoropropane, real-time detection technology, applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of container corrosion, difficult to measure accurately, large error, etc., and achieve the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

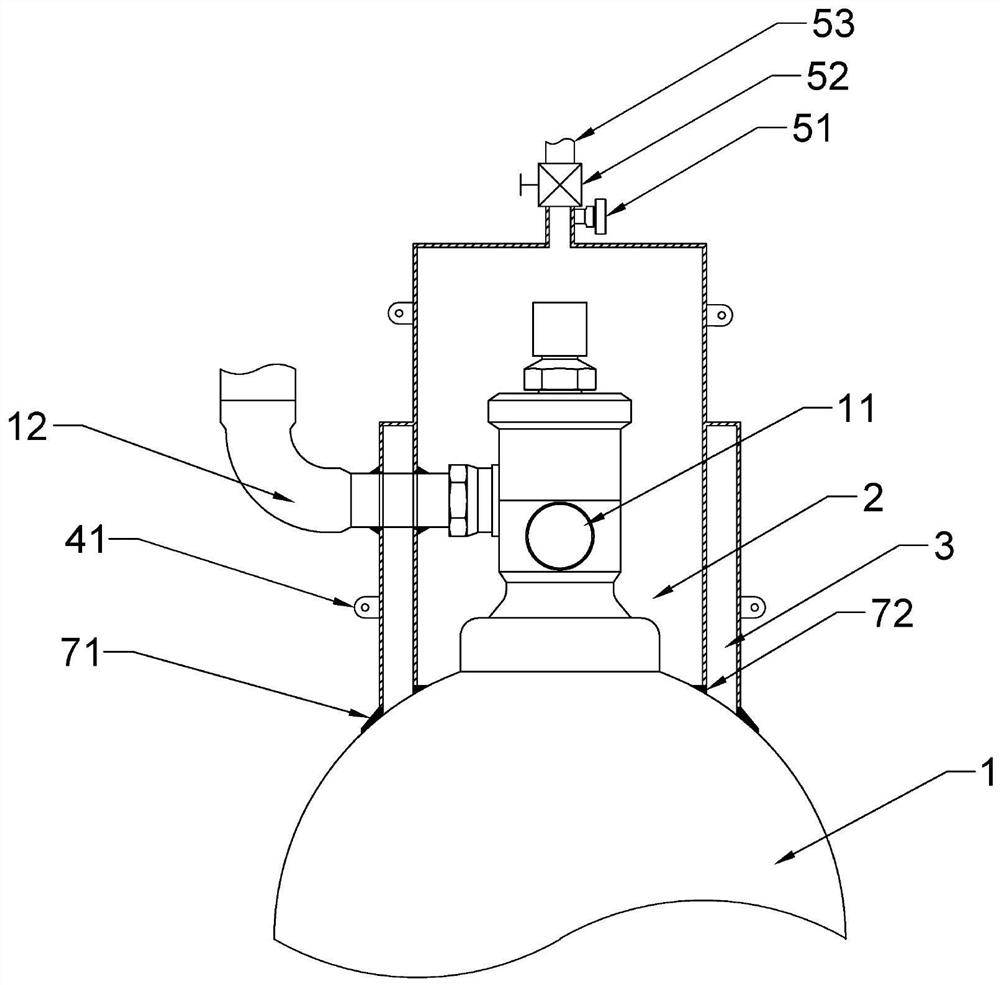

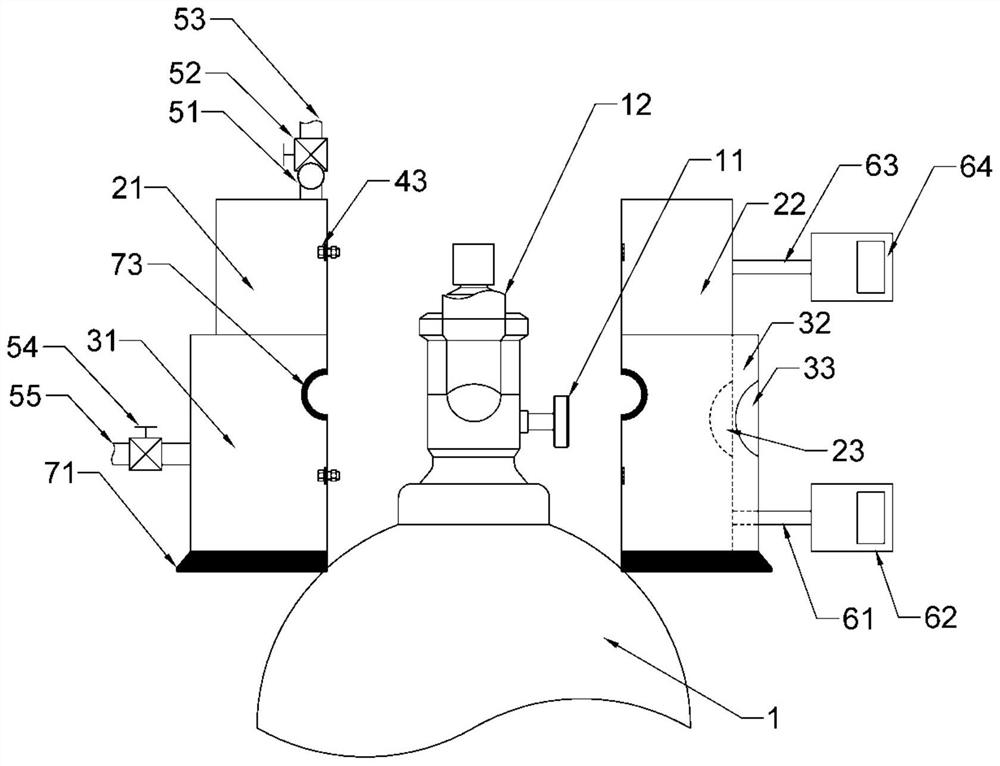

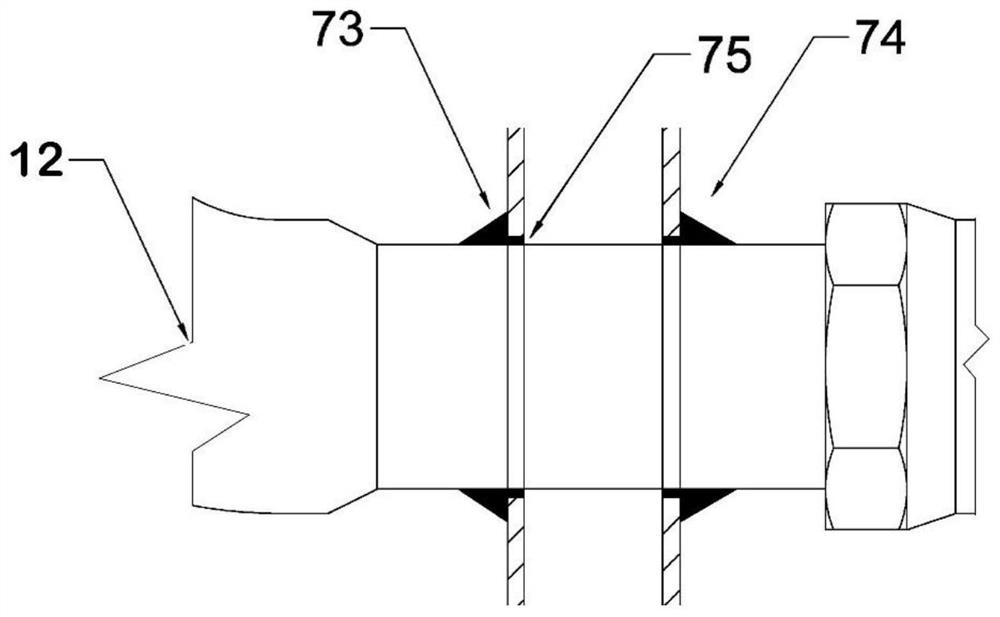

[0040] Such as figure 1 , figure 2 As shown, this embodiment is a real-time detection device for bottled high-pressure heptafluoropropane fire extinguishing agent leakage, which is installed on the bottle body 1 to be measured. The described heptafluoropropane fire extinguishing agent leakage detection device consists of a measuring chamber 2 and a vacuum fixed chamber 3 constitute the main part. The fire extinguishing agent delivery pipeline 12 passes through the opening for passing through the measuring cavity 2 and the vacuum fixed cavity 3, closes the left shell 21 of the measuring cavity and the right shell 22 of the measuring cavity, and connects the left shell 31 of the vacuum fixed cavity and the right shell of the vacuum fixed cavity. 32 is closed, so that the third sealing member 73 and the fourth sealing member 74 tightly wrap the fire extinguishing agent delivery pipeline 12, and the fire extinguishing agent delivery pipeline 12 is wrapped by the sealing ring 75,...

Embodiment 2

[0046] The difference between this embodiment and Embodiment 1 is that the bottled high-pressure heptafluoropropane fire extinguishing agent leakage detection device has been installed and the known working time is t k . Read the reading of the pressure gauge 51 and compare it with the reference pressure of 20kPa to judge the leakage state of the bottled high-pressure heptafluoropropane fire extinguishing agent; record the heptafluoropropane concentration values detected by the lower gas detection module 62 and the upper gas detection module 64, and calculate got t k The amount of leakage and the leakage rate over time.

[0047] Connect the vacuum pump to the first interface 53, open the first valve 52, extract the gas in the measurement chamber 2, and disconnect the vacuum pump from the first interface 53, so that air enters the measurement chamber 2 Inside; repeat the above pumping steps until the lower gas detection module 62 and the upper gas detection module 64 show t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap