Industrial robot electrical connector surface abrasion detection method and device

A technology for electrical connectors and industrial robots, which is applied to measuring devices, chemical instruments and methods, and optical devices, etc., can solve the problem of inability to observe the wear condition of the contact surface, cannot be used as a reliability test for connectors, and cannot completely solve the problem of connectors. crumb issues and more

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

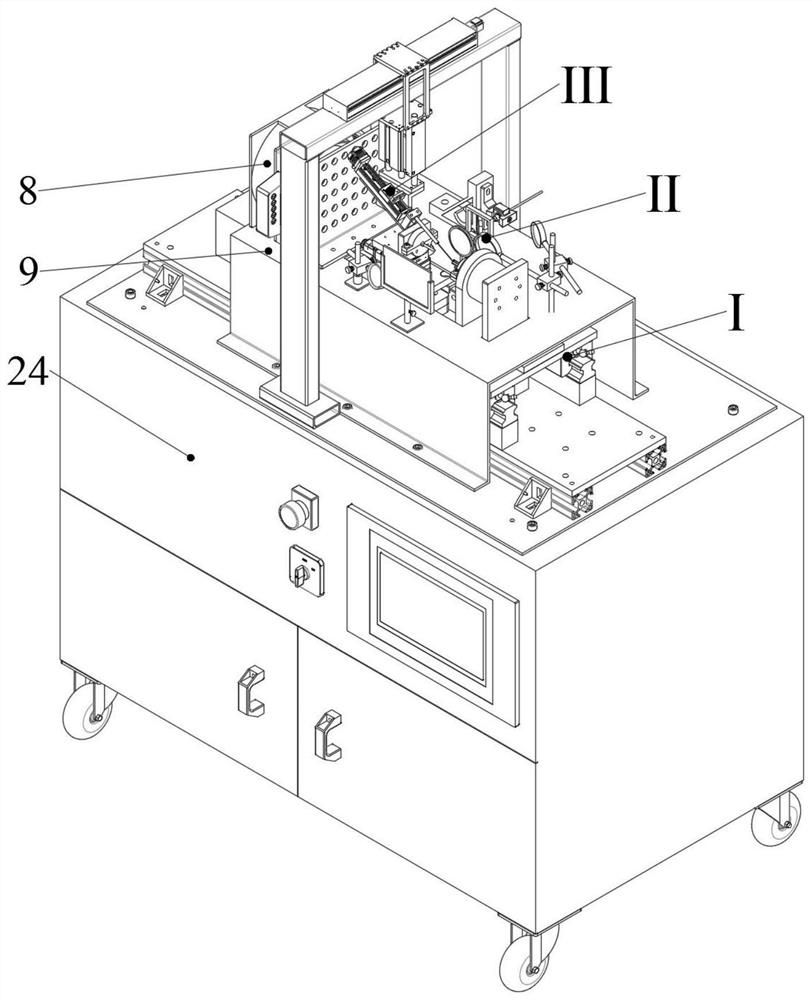

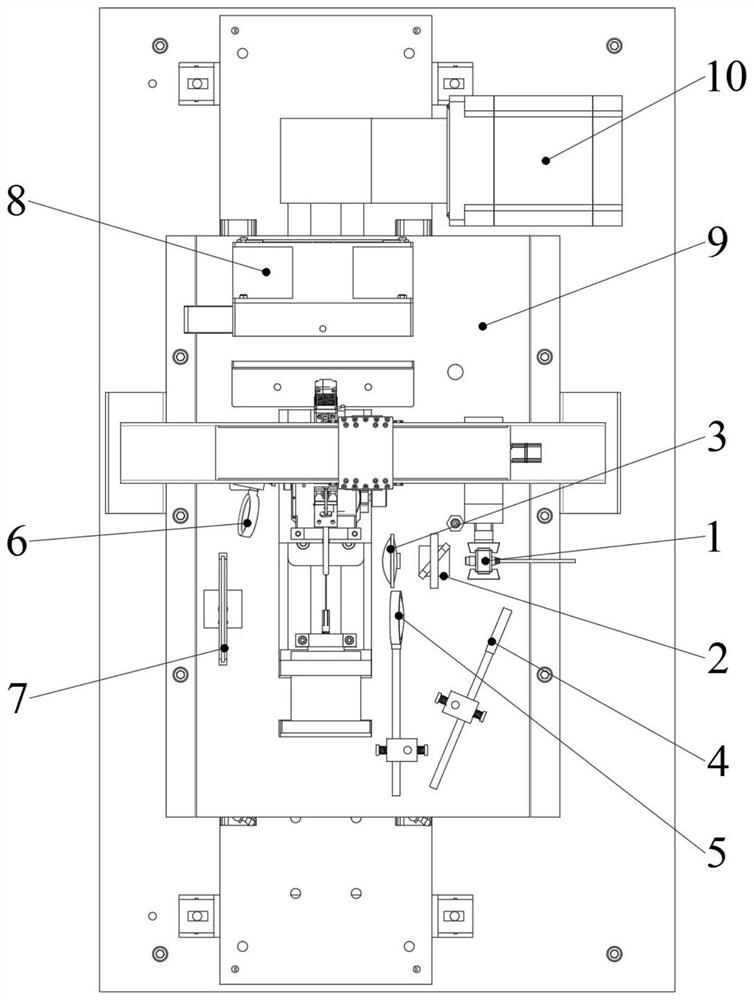

[0055] Such as figure 1 , 2 , 3, 4 and 5, a kind of industrial robot electrical connector surface wear detection and wear debris cleaning device, including test box 24 (the top case shell is hidden), connector plug-in module I, fan heater 8, Surface roughness detection module II and cleaning module III. The connector plug-in module, the surface detection module and the fan heater 8 are all installed on the test box 24 through the heat shield 9 . The fan heater 8 faces the plug-in module for adjusting the temperature of the plug-in.

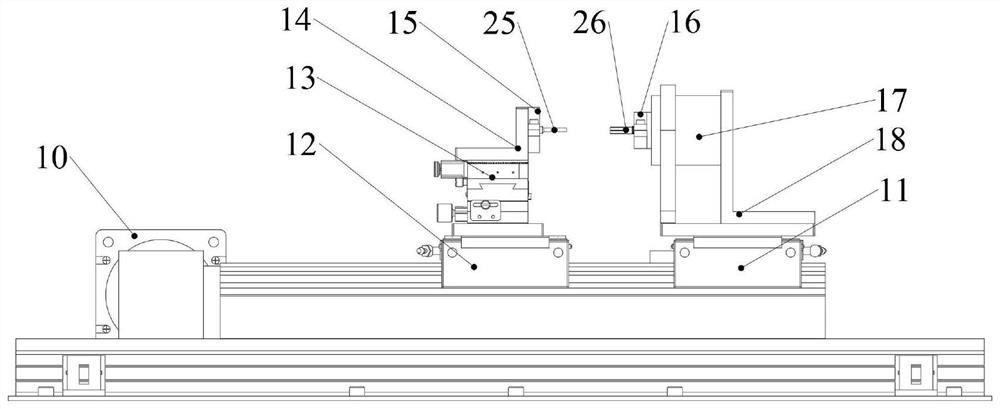

[0056] The connector plug-in module includes a plug-in electric slide table, a miniature electric rotary table 13, a male end L plate 14, a male end clamp 15, a female end clamp 16, a three-way force sensor 17 and a female end L plate 18. The plug-in electric slide table includes two guide rails, two movable sliders 12, two fixed slide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com