A Bearing Fatigue Life Prediction Method for Huge Ring-hugging Tire Unloading Machine

A fatigue life prediction and fatigue life technology, applied in the field of tire unloaders, can solve the problems of bearing failure, complex bearing force in key parts, strong vibration, etc., and achieve the effect of scientific analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

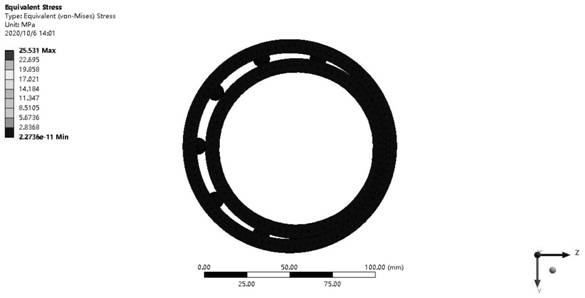

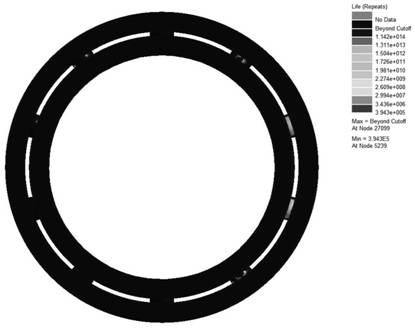

[0030] The present invention is a bearing fatigue life prediction method of a ring-enclosed giant tire unloader. The mechanical structure of the tire unloader is as follows: figure 1 As shown, the tire unloader has a total of 8 guide wheels and 16 pairs of rocker arms. Each guide wheel and the rocker arm are equipped with two deep groove ball bearings, which are used for the bearings at the rocker arm of the tire unloader and the bearings at the guide wheels. Bearings are subjected to fatigue life prediction; the method includes the following steps:

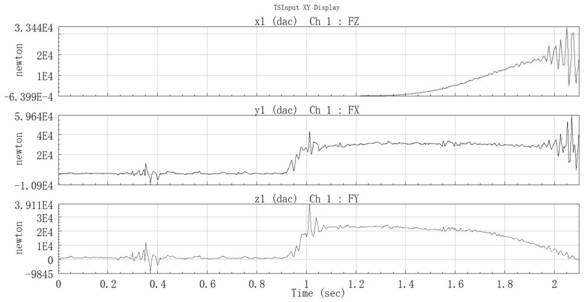

[0031] 1) Build a tire unloader model and perform dynamic simulation analysis on the tire unloader as a whole, such as figure 2 Add the overall constraints and drives to the tire unloader model, simulate the operation of the tire unloader, and obtain the load spectrum of the bearing at the bottom rocker arm and the bearing at the top guide wheel on the tire unloader (the load spectrum includes the vertical force load spectrum, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com