Chip transfer robot

A chip transfer and manipulator technology, applied in the direction of conveyor objects, electrical components, transportation and packaging, etc., can solve the problems of single function of the manipulator, low production efficiency, large workshop area, etc., to improve production efficiency, improve positioning accuracy, Effect of less workshop area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] As mentioned above, in the prior art, due to the single function of the manipulator, it is necessary to use two or more manipulators to transfer the chips, which occupies a large area of the factory building, has low production efficiency and high cost.

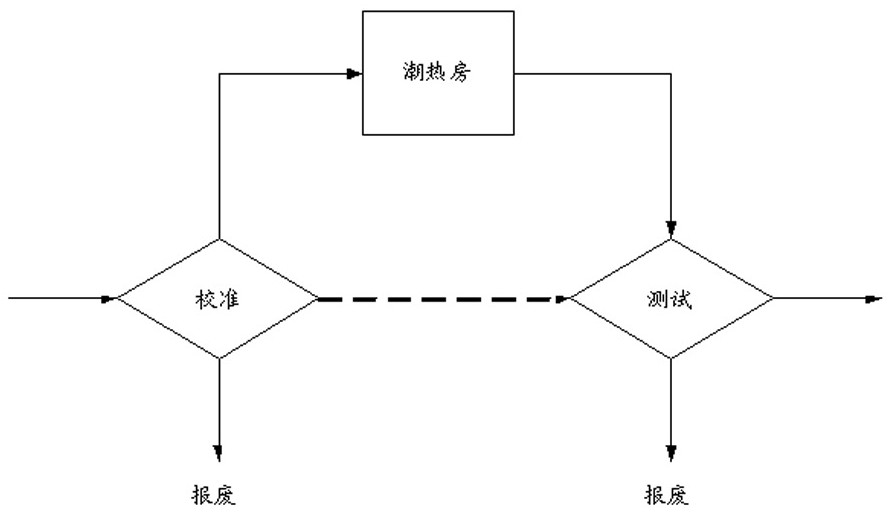

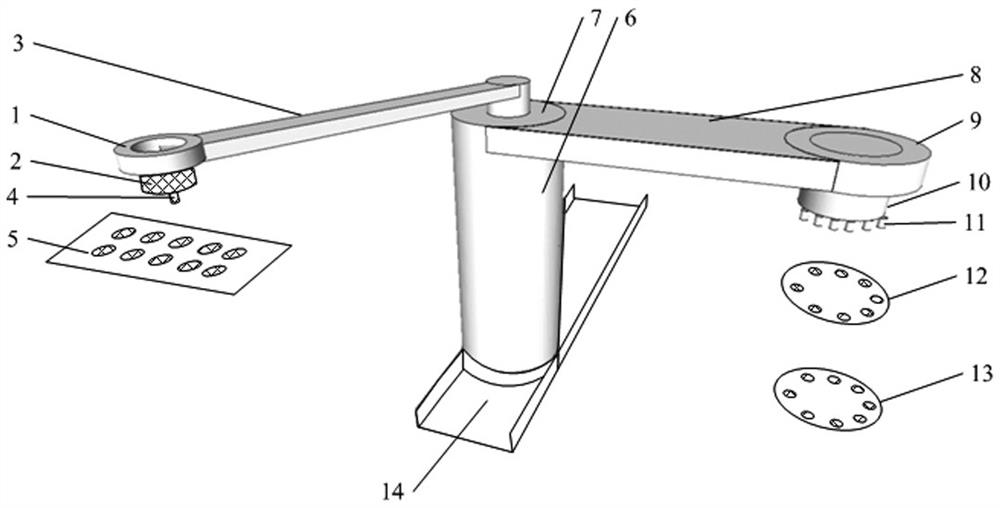

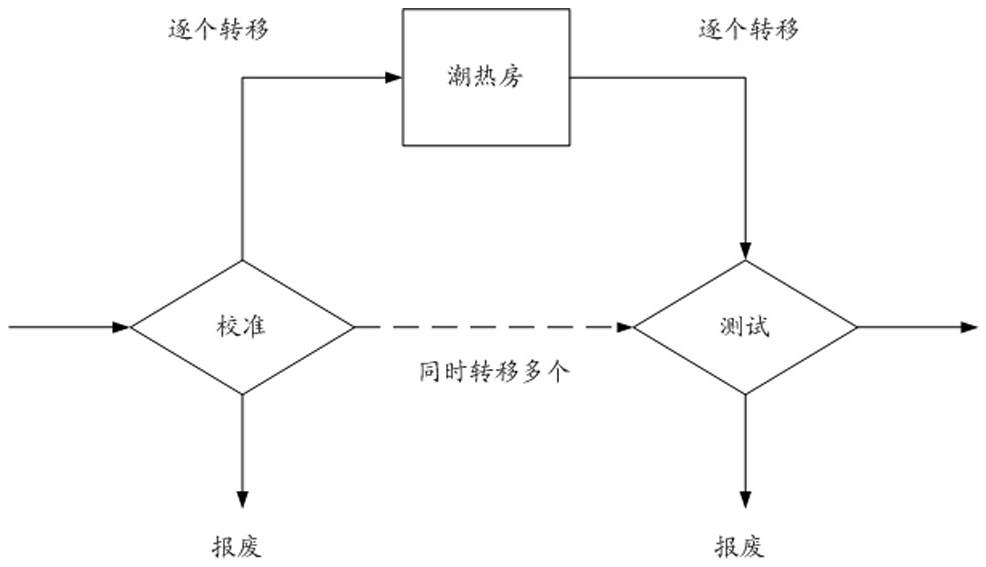

[0027] refer to figure 1 , figure 1 It is a schematic diagram of a working scene of a chip transfer manipulator in the prior art.

[0028] Specifically, such as figure 1 As shown in the straight line path, the chip transfer robot can be used in the chip measurement stage, including baking and testing the chip.

[0029] More specifically, the chip can be calibrated and burned first, and the abnormal bad chips are screened out and put into the bad product box for scrapping.

[0030] Then, use the robot to place the chip into the baking tray, send it into the hot flash room or humidification box for baking, so that the steam enters the chip through the acoustic space, so that various foreign objects on the chip appea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com