Odor collecting system and method

A collection system and odor technology, applied in the direction of cleaning methods using gas flow, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problem of large deviation of design values, difficulty in achieving precise control, and difficulty in achieving effective suction Negative pressure and other problems, to achieve the effect of precise collection and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

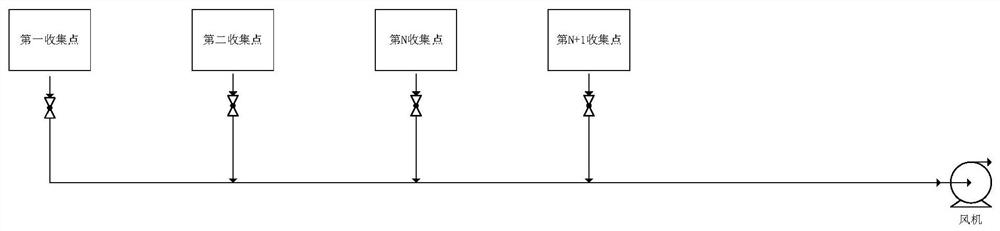

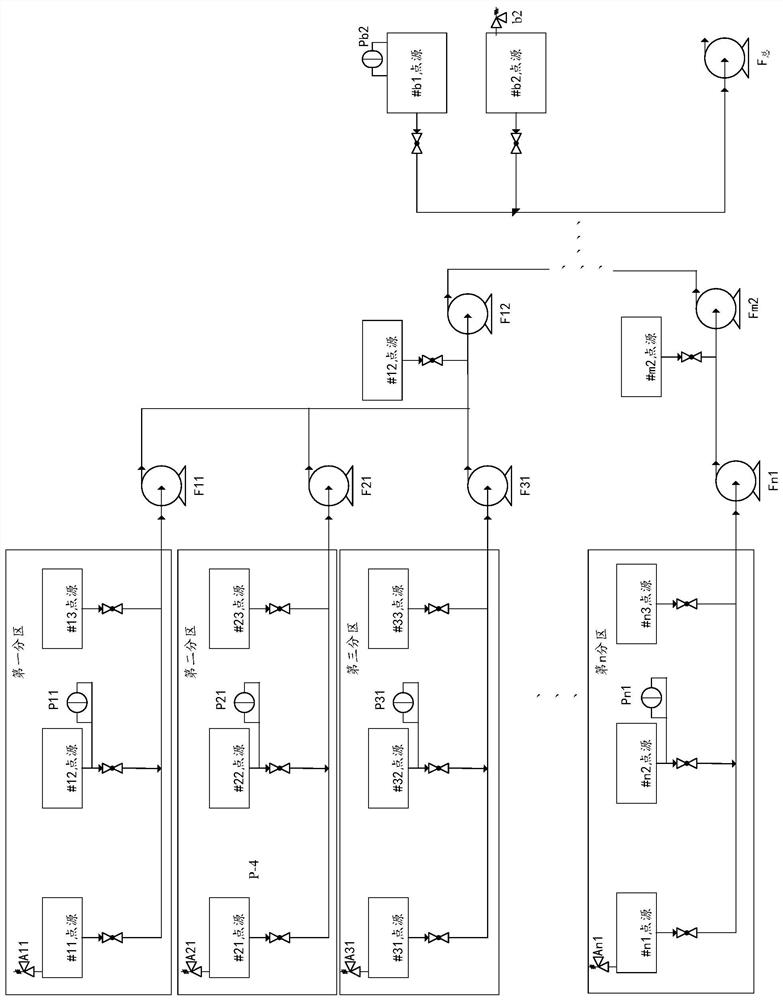

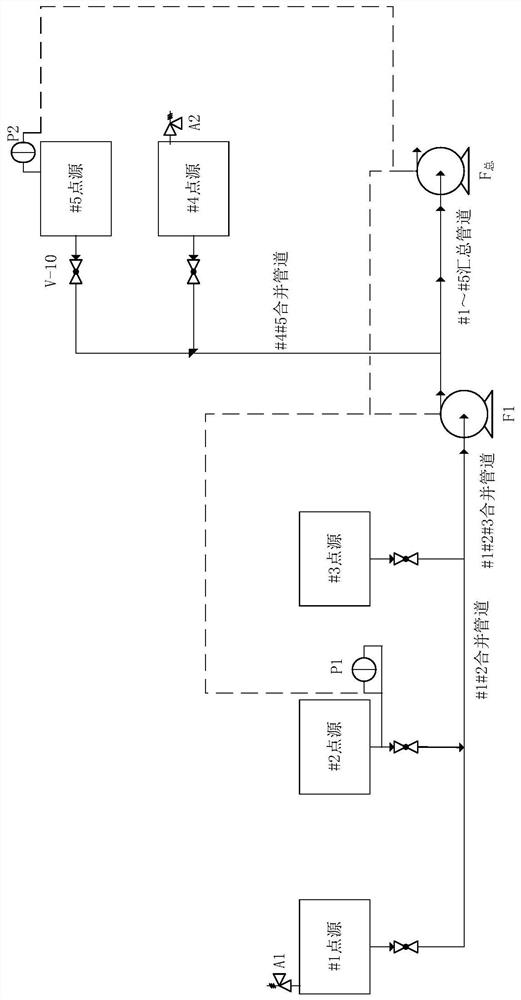

[0032] Such as figure 2 As shown, the odor collection system of this embodiment includes a control unit and a plurality of collection branch pipes, and the collection branch pipes are used to collect odor from odor point sources; multiple point sources are divided into multiple areas, and points in each area The collection branch pipes corresponding to the source are connected to a first-level main pipe. One end of the collection main pipe is provided with a first-level fan. Each first-level fan is divided into multiple groups. The second-level fan is connected, and so on, until all n-level fans are connected to the main fan through the main duct; among them, the second-level fan to the n-level fan and the main fan are connected to at least one independent collection pipe; in each area At least A first pressure detection piece is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com