Anti-collision lithium battery pack welding device

A lithium battery pack and welding device technology, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve problems such as low efficiency, inability to realize automatic docking between welding sheets and lithium battery packs, etc., and achieve the effect of automatic docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

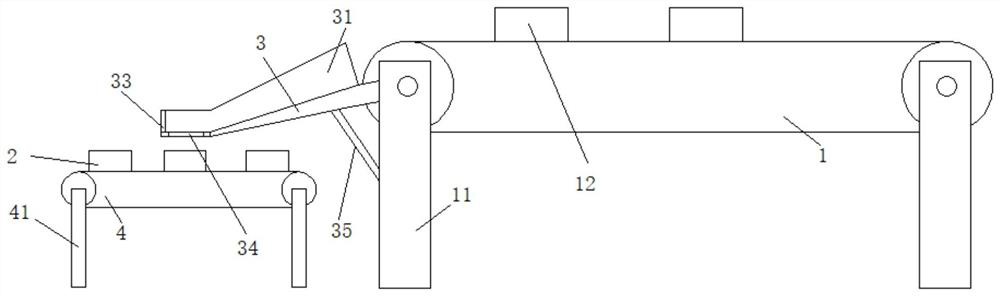

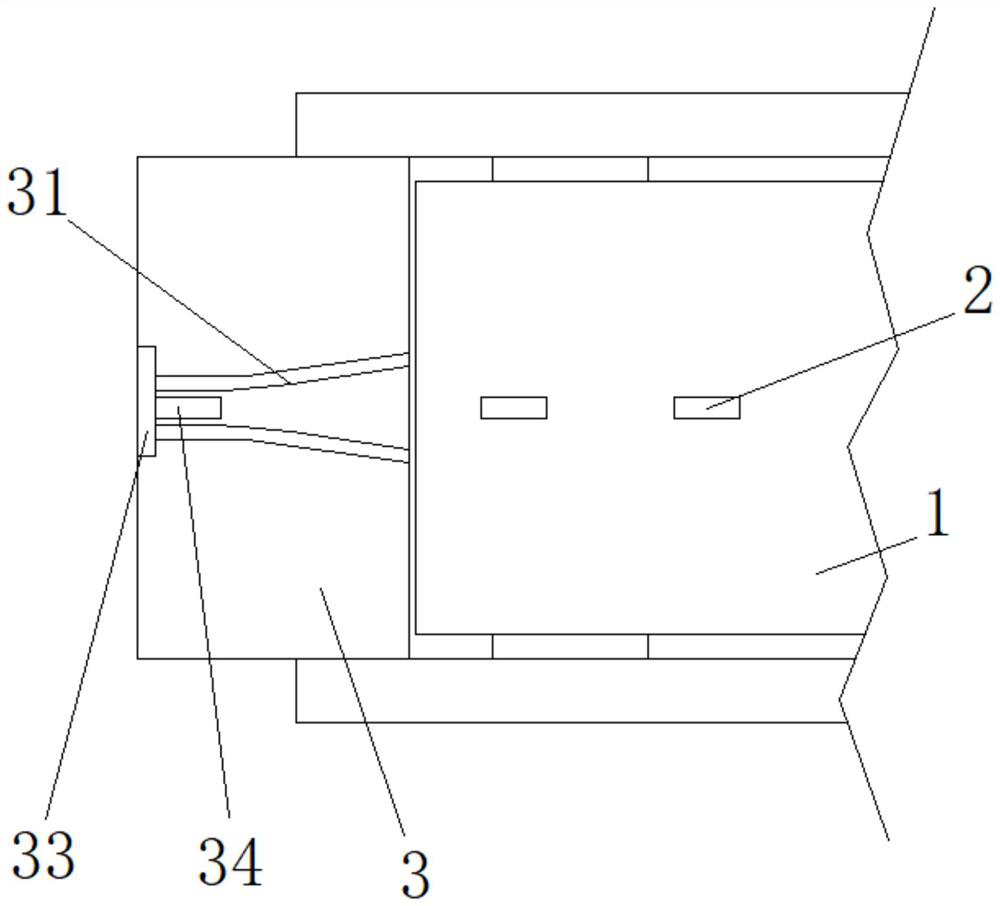

[0031] see Figure 1-3 , a collision-proof lithium battery pack welding device, including a first conveyor belt 1, a second conveyor belt 4 and a transfer plate 3, the first conveyor belt 1 is provided with evenly distributed lithium battery packs 12, and the second The output end of a conveyor belt 1 is provided with an inclined downward transfer plate 3, and the transfer plate 3 is provided with symmetrically distributed deflectors 31, and the extension end of the transfer plate 3 is provided with a fixedly connected baffle plate 33 The baffle 33 and the deflector 31 are connected and fixed to each other, and the transfer plate 3 on one side of the baffle 33 is provided with a transfer hole 34, and the transfer hole 34 is provided with a symmetrical distribution. and a telescopic positioning plate 341, and a second conveyor belt 4 is provided below the transfer hole 34, and the positioning box 2 that is evenly distributed and matched with the lithium battery pack 12 is provi...

Embodiment 2

[0038] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

[0039] see Image 6 The baffle plate 33 is provided with a pressure sensor 32 for sensing, and the inner walls of both sides of the transfer hole 34 are provided with symmetrically distributed adjusting grooves 342, and the positioning plate 341 is slidably connected in the adjusting groove 342, so that A fixedly connected second hydraulic rod 343 is arranged inside the adjustment groove 342 , and the extension end of the second hydraulic rod 343 is connected and fixed to the end of the positioning plate 341 .

[0040] The design of the pressure sensor 32 realizes the automatic control of the lithium battery pack 12 through the induction of the pressure sensor 32 and improves the overall efficiency.

[0041] Further, the second hydraulic rod 343 is an electro-hydraulic push rod, and the pressure sensor 32 is electrically connected to the second hydraulic rod 343 .

Embodiment 3

[0043] The same as embodiment 1 is not repeated, and the difference with embodiment 1 is:

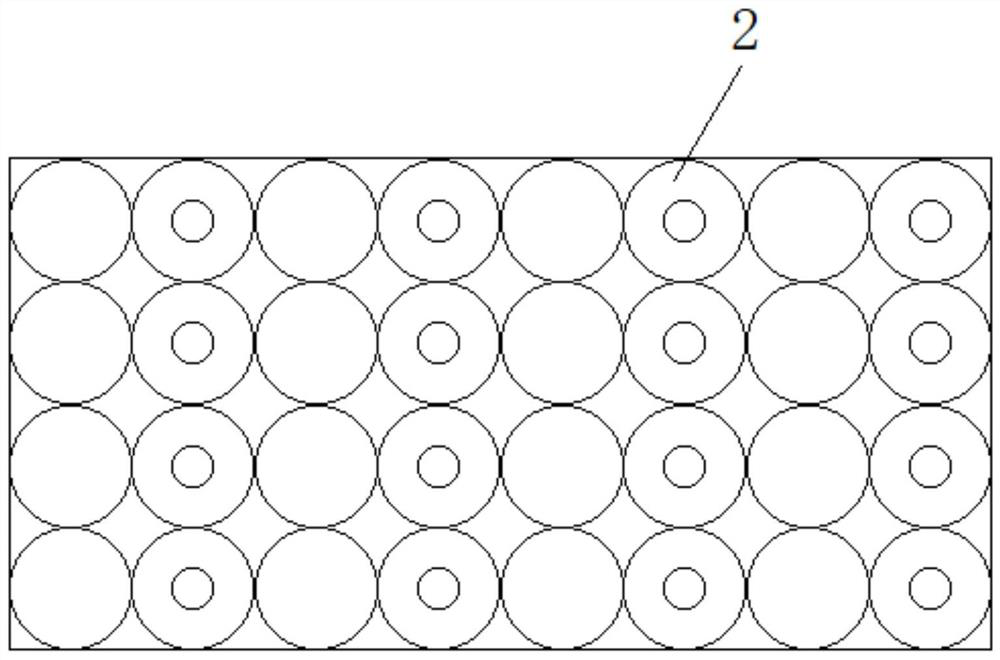

[0044] see Figure 7-8 , the positioning box 2 is a square frame, and the positioning box 2 is provided with a welding plate 21 that can move up and down. The middle part of the welding plate 21 is provided with a welding hole 23 for welding. The welding plate 21 is provided with a welding groove 22 for engaging the welding piece 24 .

[0045]The unique design of the positioning box 2 enables the welding plate 21 to move upwards directly when the first hydraulic rod 51 rises, so that the welding plate 21 can be closer to the transfer hole 34, effectively preventing the lithium battery pack 12 from automatically When falling, the distance is too far, resulting in vibration damage to the lithium battery pack 12, and can effectively improve the drop accuracy of the lithium battery pack 12. When the first hydraulic rod 51 descends, the positioning box 2 contacts the second conveyor belt 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com