Pellet composite binder for widening moisture range of pelletizing raw materials and using method of composite binder

A binder and organic binder technology, applied in the field of composite binders for pellets, can solve the problems of narrow suitable water range for pelletizing, and achieve the effect of improving the quality of green pellets and alleviating bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

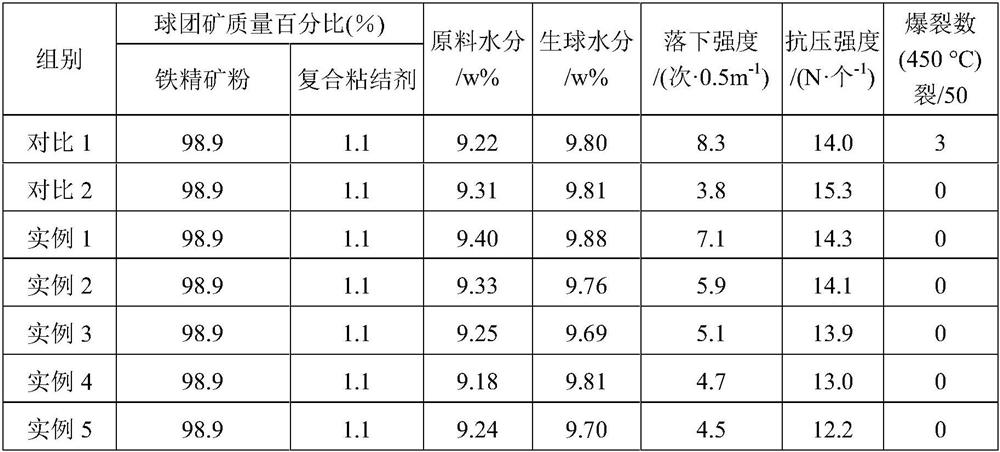

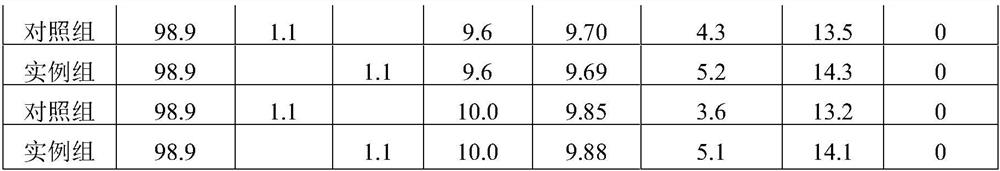

Examples

Embodiment 1

[0021] The invention relates to a composite binder for pellets which widens the water range of pelletizing raw materials, and its component mass percentage is: 90% of sodium bentonite and 10% of composite organic binder. The mass percent of the composite organic binder is 40% of water-absorbing resin; 20% of sodium humate; 20% of carboxymethyl cellulose sodium; and 20% of polyacrylamide. All components are mixed according to the proportion.

Embodiment 2

[0027] The invention relates to a composite binder for pellets which widens the water range of pelletizing raw materials, and its component mass percentage is: 90% of sodium bentonite and 10% of composite organic binder. The mass percentage of the composite organic binder is 45% of water-absorbing resin; 18% of sodium humate; 18% of carboxymethyl cellulose sodium; and 19% of polyacrylamide. All components are mixed according to the proportion.

Embodiment 3

[0029] The invention relates to a composite binder for pellets which widens the water range of pelletizing raw materials, and its component mass percentage is: 90% of sodium bentonite and 10% of composite organic binder. The mass percent of the composite organic binder is 50% of water-absorbing resin; 15% of sodium humate; 17% of carboxymethyl cellulose sodium; and 18% of polyacrylamide. All components are mixed according to the proportion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com