Quick insertion locking joint

A fast technology for locking joints, which is applied in the direction of pipes/pipe joints/fittings, packing seals with fluid pressure, passing components, etc. It can solve problems such as complex structures, large handles occupying space, and time-consuming and labor-intensive quick joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

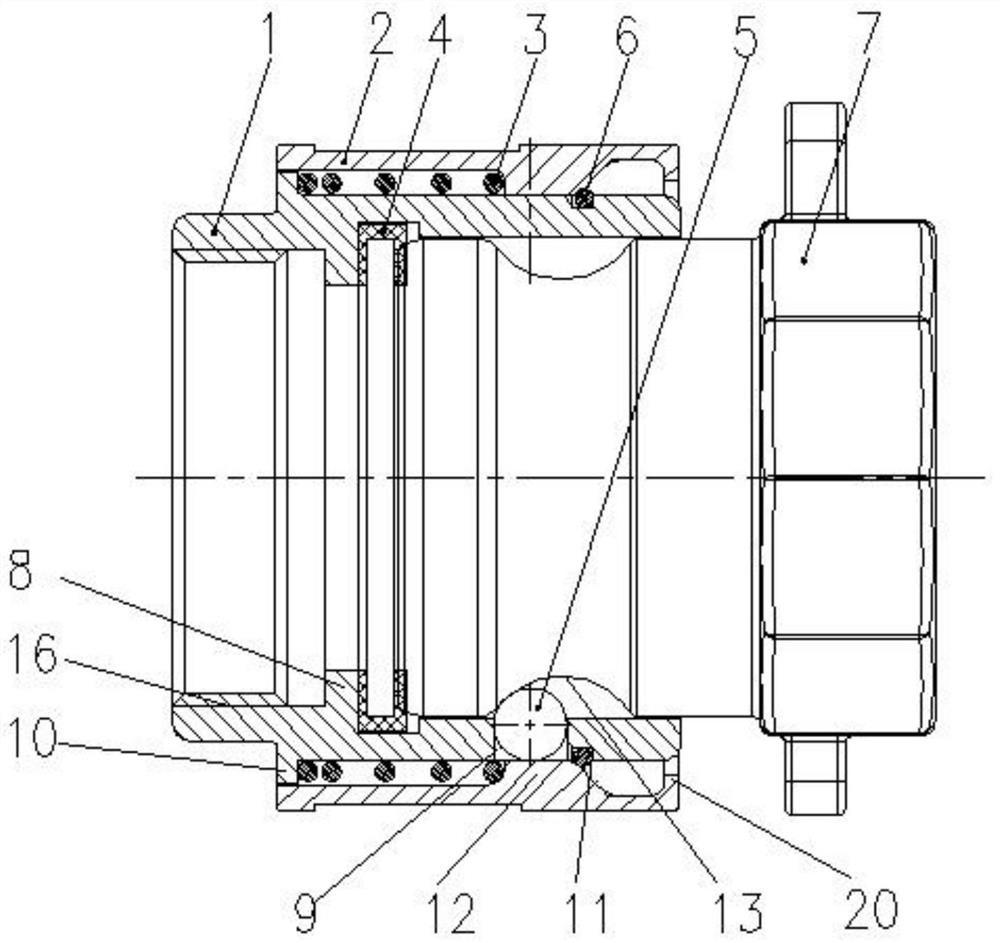

[0030] Such as figure 1 As shown, this embodiment provides a quick insertion locking joint, including a female body 1, a sliding sleeve 2, an elastic element 3, a sealing ring 4, a limiting element 5 and a retaining ring 6, and one end of the female body 1 is provided with a plug Interface, the socket is used to connect the Camlock male connector 7, the inner wall of the socket is provided with a sealing seat 8, the sealing ring 4 is arranged on the side of the sealing seat 8 close to the port of the socket, and the side wall of the socket is provided with a plurality of limit holes 9 Each limit hole 9 is provided with a limit element 5 and the limit hole 9 can limit the limit element 5 to break away from the limit hole 9 inwardly, and the outer wall of the female head body 1 is provided with a first boss 10, The sliding sleeve 2 is sleeved outside the first boss 10, and the outer wall of the female head body 1 is provided with a card slot 11, and the card slot 11 is arranged...

Embodiment 2

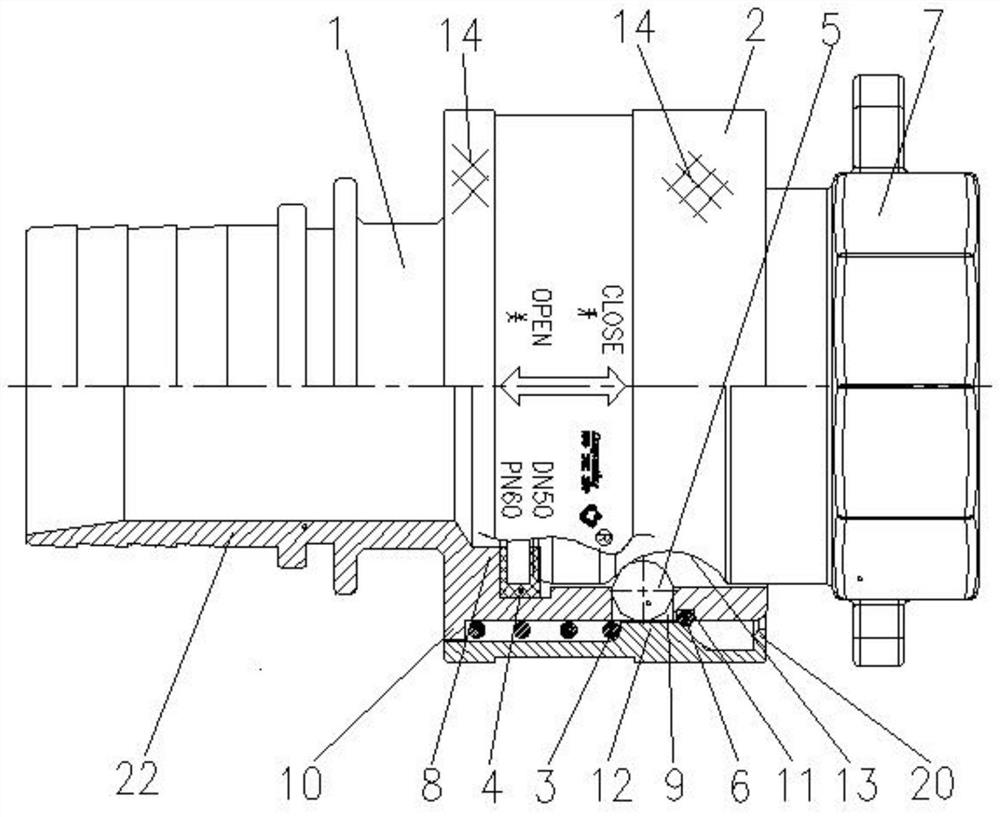

[0038] Such as figure 2 As shown, this embodiment provides a quick-insert locking joint, which is different from the quick-inserting locking joint in Embodiment 1 in that the outer surface of the sliding sleeve 2 is provided with anti-slip mesh protrusions 14, which can increase the sliding The frictional force between the cover 2 and the hand facilitates pushing the sliding cover 2.

[0039] Wherein, the connection port for connecting with the pipe fitting is set as a tail pipe 22, through which the tail pipe 22 is connected with the pipe fitting.

Embodiment 3

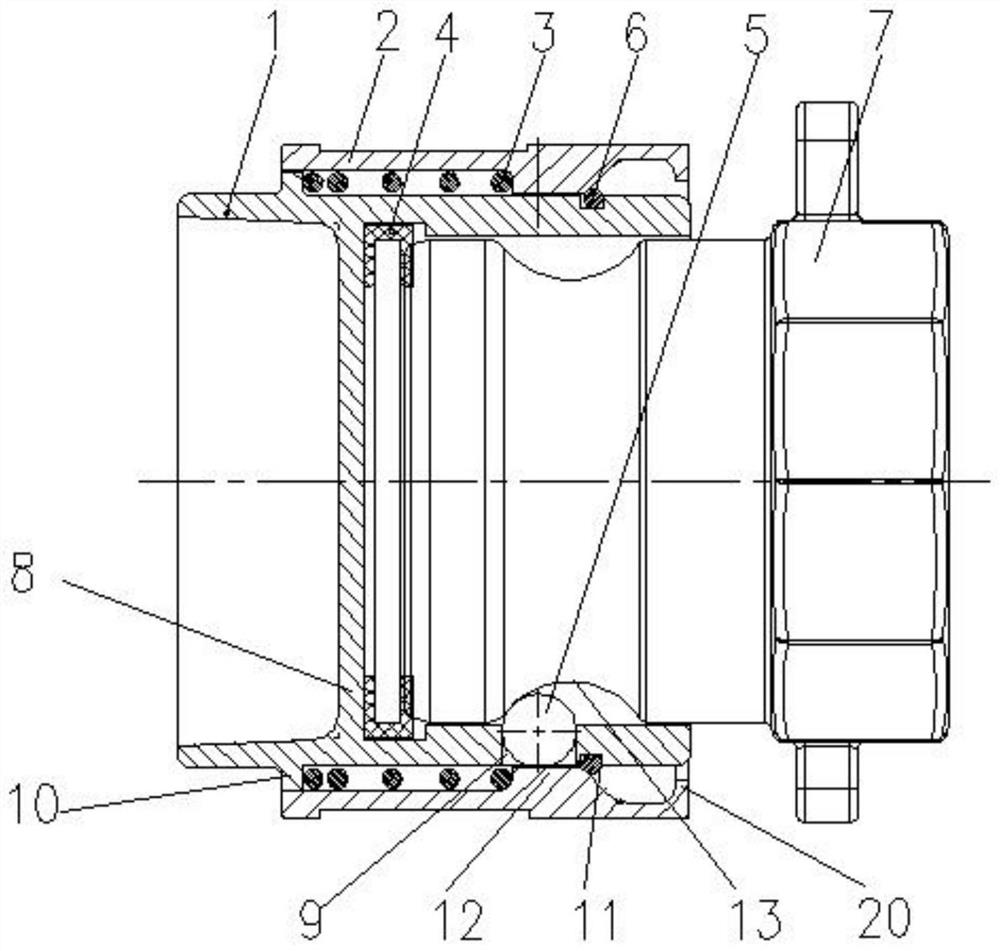

[0041] Such as image 3 As shown, in the quick insertion locking joint provided in this embodiment, the sealing seat 8 is a sealing partition, and the sealing partition seals the end of the female head body away from the socket, and the sealing ring 4 is arranged on the sealing partition close to the port of the socket. On one side, through the setting of the sealing partition, the pipe fittings can be sealed and dust can be prevented from entering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com