Method for realizing automatic early warning of production process quality based on IFIX

An automatic early warning and production process technology, applied in program control, electrical program control, comprehensive factory control, etc., can solve the problem that quality indicators cannot be alarmed in real time, and achieve the effect of reducing the labor intensity of employees, realizing real-time monitoring, and ensuring stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate those skilled in the art to understand and realize the present invention, the technical solution of the present invention is now further described in conjunction with the drawings and specific embodiments.

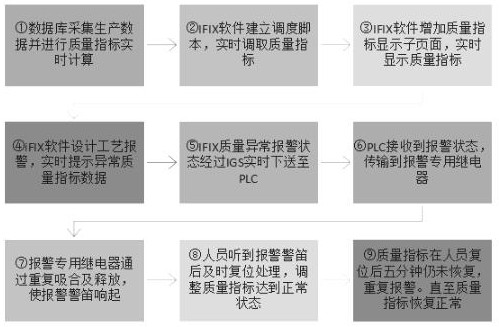

[0021] Described method comprises that step 1 database collects production data and carries out quality index real-time calculation, step 2, IFIX software establishes scheduling script, transfers quality index in real time, step 3, FIX software increases quality index display sub-page, real-time display quality index, Step 4, ifix software design process alarm, prompt abnormal quality index data in real time, step 5, IFIX quality abnormal alarm status is sent to PLC in real time through IGS, step 6, PLC receives alarm status, transmits to alarm special relay, step 7, The alarm special relay makes the alarm siren sound through repeated pull-in and release. Step 8, the personnel reset in time after hearing the alarm siren, and adjust the quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com