Side wall clamping and pressing type seed metering device

A seed metering device and seed technology, which is applied to sowing, single-grain seeding machines, planting machine parts, etc., can solve the problems of long manufacturing process, waste of seeds, and difficult manufacturing, etc., and achieve the effect of simple structure, easy manufacturing, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

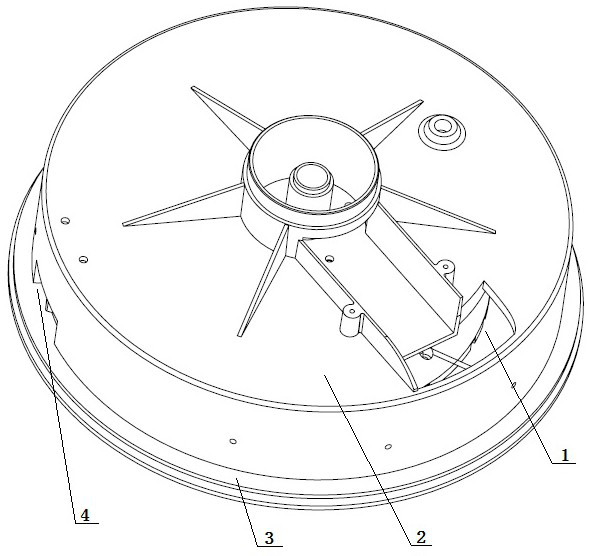

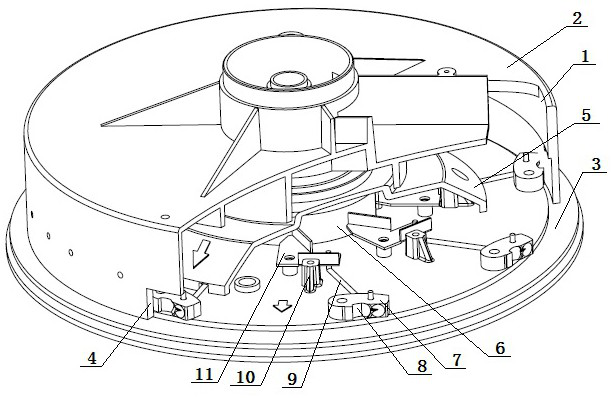

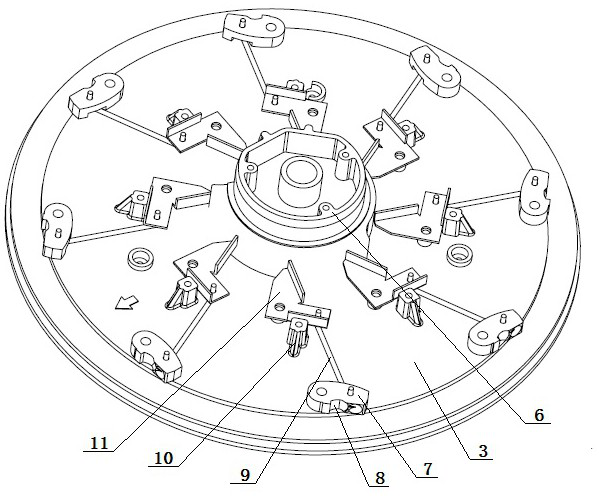

[0023] see Figure 1-5 , Embodiment 1, the present embodiment is a kind of side wall clamping type seed metering device, which includes chassis 3, cam 6, clamping type seed taking assembly, partition cover 5 and seed bin cover 2, and the above described chassis 3 is provided with the same The cam 6 of the shaft is matched with a gap, and the eight clamp-type seed-taking components are placed on the chassis 3 and arranged evenly along the circumference. One end of the clamp-press-type seed-taking component extends into the partition 5 and contacts the side wall of the cam 6. The partition cover 5 is placed on the cam 6 and the pinch type seed-taking assembly, and is sleeved on the cam 6 with a clearance fit. The seed bin cover 2 is placed on the chassis 3, and the mouth is in contact with the chassis 3. The seed bin cover 2. The inner side wall is in co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com