Forming die for producing nickel-zinc ferrite magnetic core

A technology of nickel-zinc ferrite and forming molds, applied in the directions of molds, forming indenters, ceramic forming machines, etc., can solve problems such as high cost, disadvantageous mass production, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

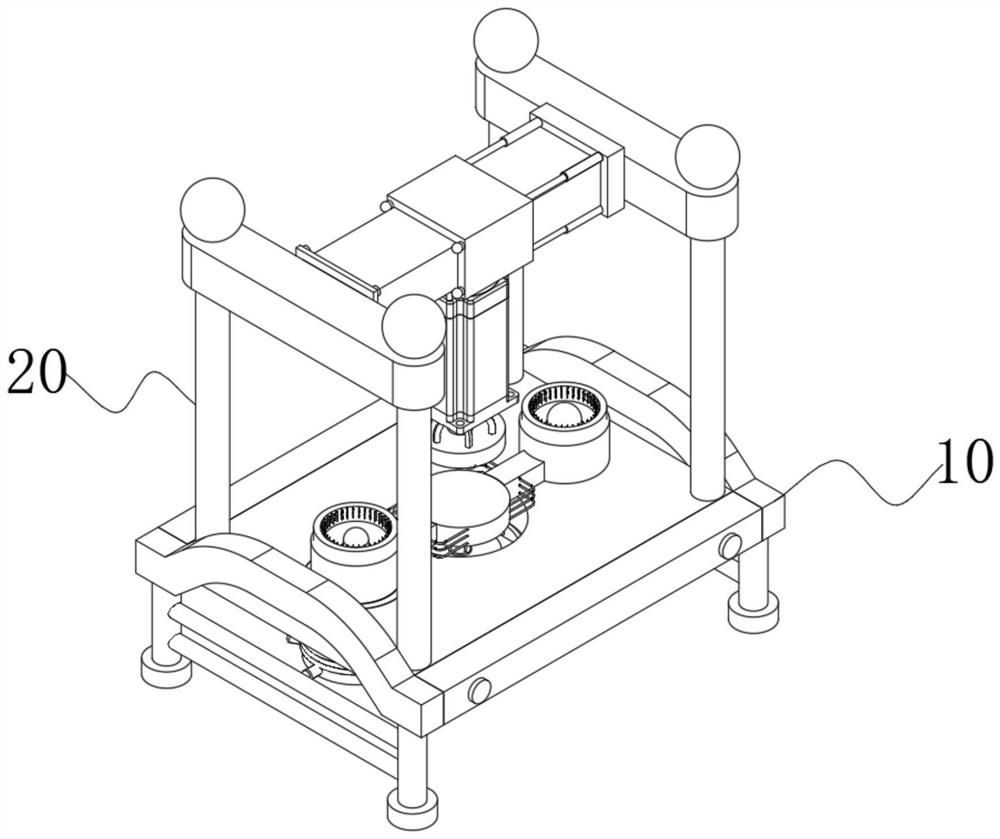

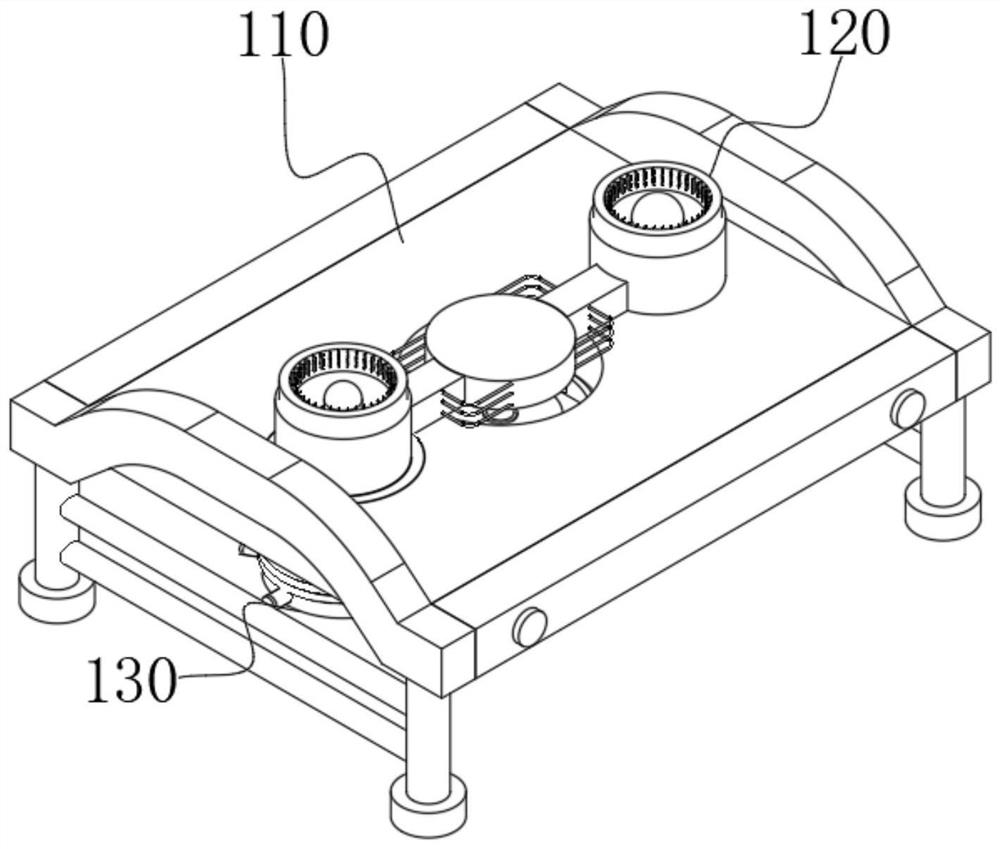

[0072] see Figure 1-Figure 11 As shown, there is provided a molding die for nickel-zinc ferrite core production, including a mold base 10 and an extrusion device 20 installed on the top of the mold base 10, and the mold base 10 at least includes;

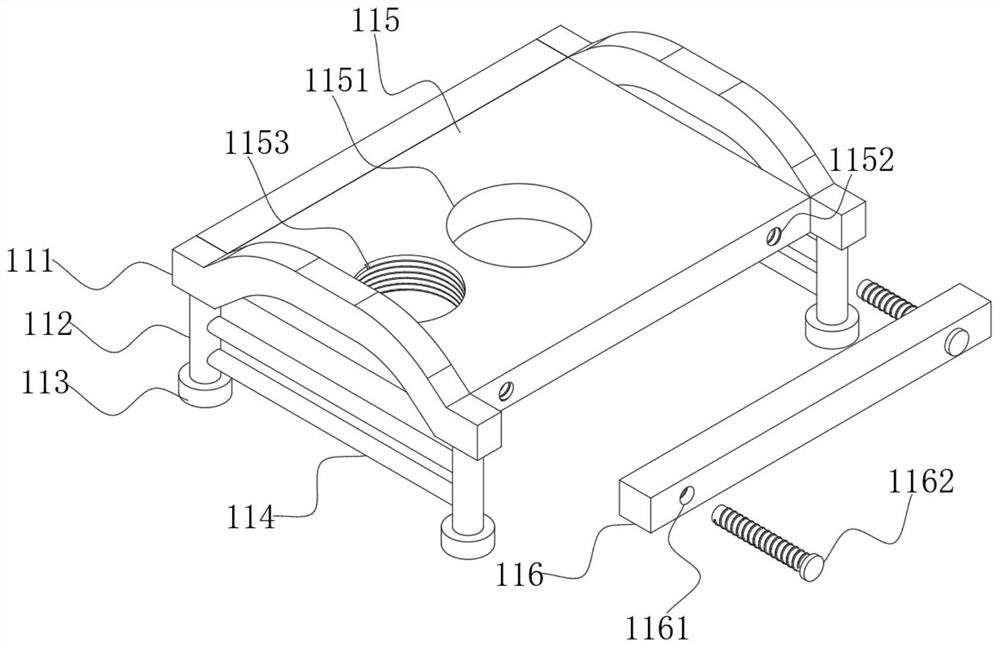

[0073] Mold plate 110, the mold plate 110 includes a pair of support frames 111, support columns 112 are installed on the bottom ends of both sides of the support frames 111, support plates 113 are installed on the bottom ends of the support columns 112, and a pair of horizontal rods are connected between the two support columns 112 114, a bottom plate 115 is connected between the two support frames 111, a fixing hole 1151 is provided in the middle of the top of the bottom plate 115, a pair of first internal threads 1152 are provided on both ends of the bottom plate 115, side plates 116 are installed on both ends of the bottom plate 115 ;

[0074] Mold forming device 120, the mold forming device 120 includes a turntable 121, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com