Forming method of bullet train hood of carbon fiber sandwich structure

A sandwich structure and molding method technology, applied in the field of motor vehicle hoods, can solve the problems of inability to locate the internal mounting surface, etc., and achieve the effects of stable size, good heat insulation and sound insulation performance, and good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with drawings and embodiments.

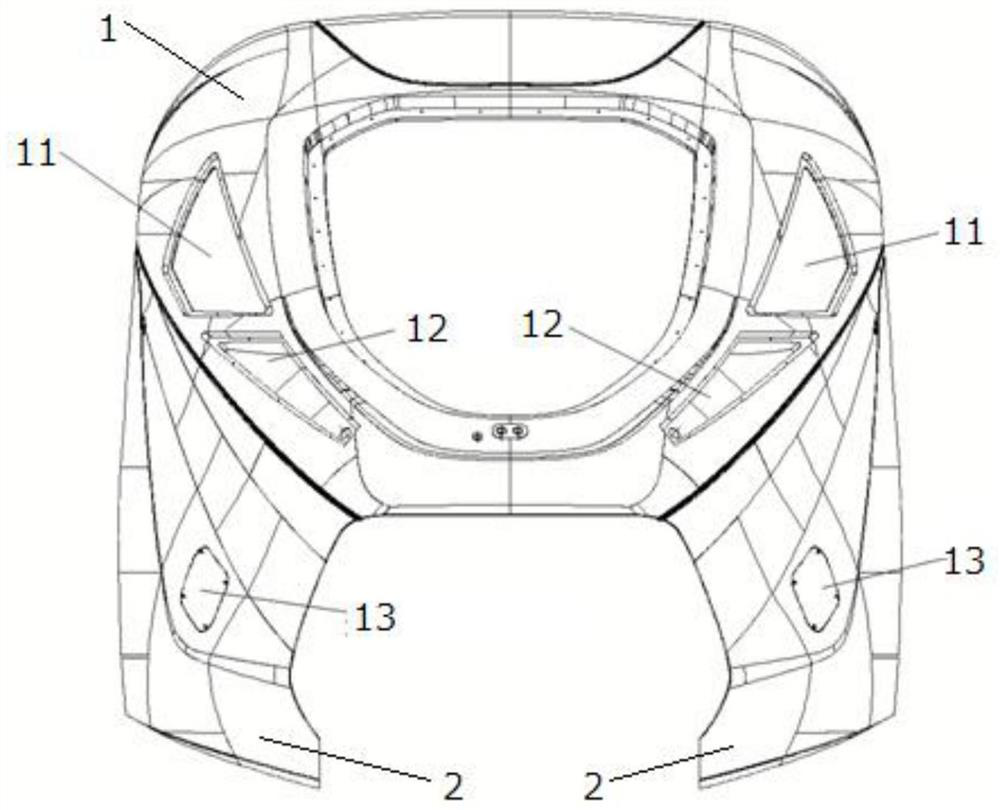

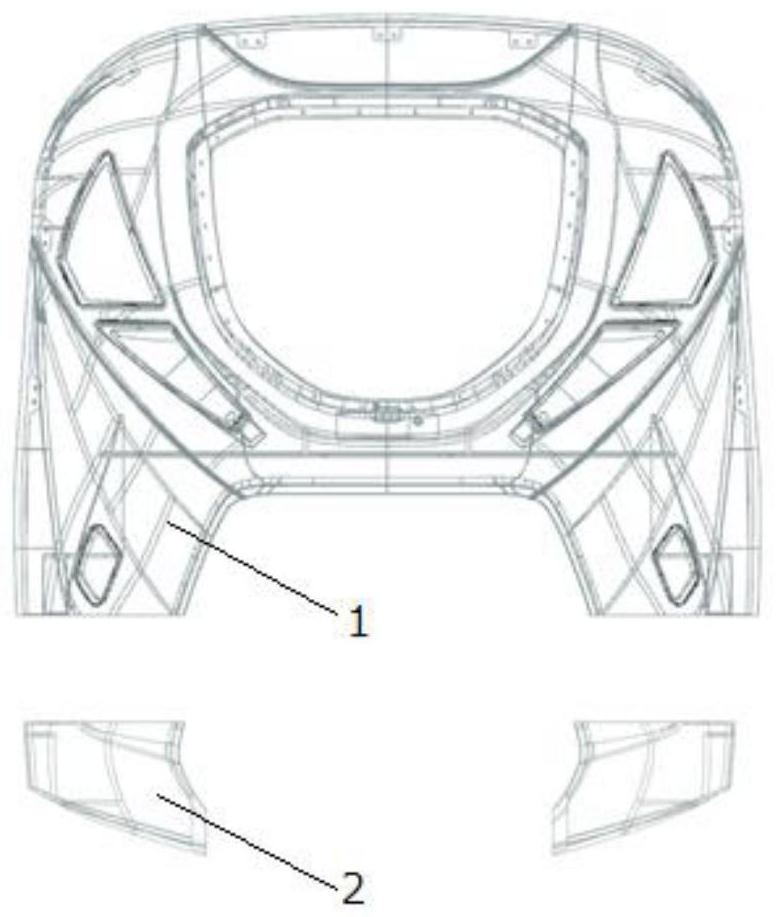

[0035] A method for forming the head cover of a carbon fiber sandwich structure, using such as Figure 1~5 Shown mold makes headgear, and this forming method comprises the following steps:

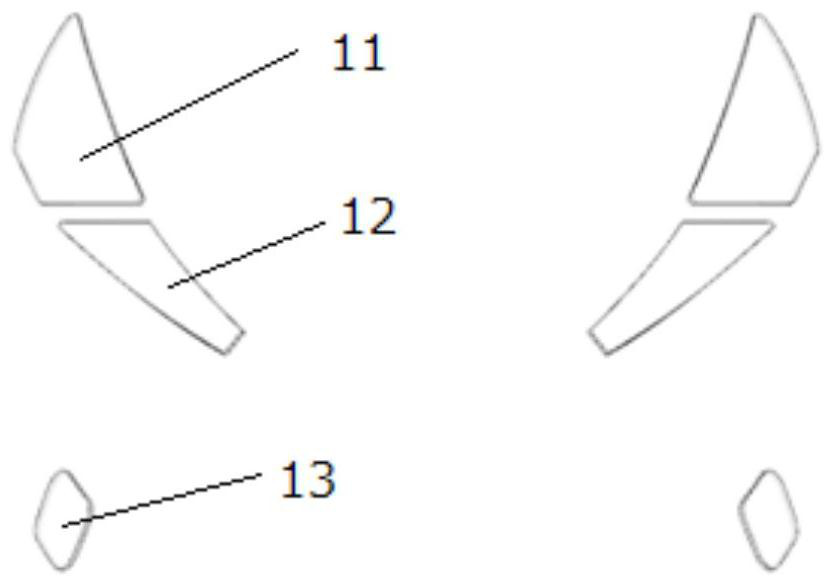

[0036] 1) Clean the first installation block 11, the second installation block 12 and the third installation block 13 with alcohol or acetone, and then install the first installation block 11, the second installation block 12 and the third installation block 13 respectively on the The inner side of the main form 1 corresponds to the position of the side window, the lamp house and the inspection door; then install the flange side mold 3 horizontally on the bottom of both sides of the main form 1, and ensure that one side of the flange side mold 3 extends into the main form 1 internal;

[0037] 2) Apply a release agent on the main mold 1, the first installation block 11, the second ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap