Full-automatic battery cell film tearing machine and film tearing process thereof

A fully automatic, battery-powered technology, applied in the field of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The present invention will be further described below in conjunction with accompanying drawing:

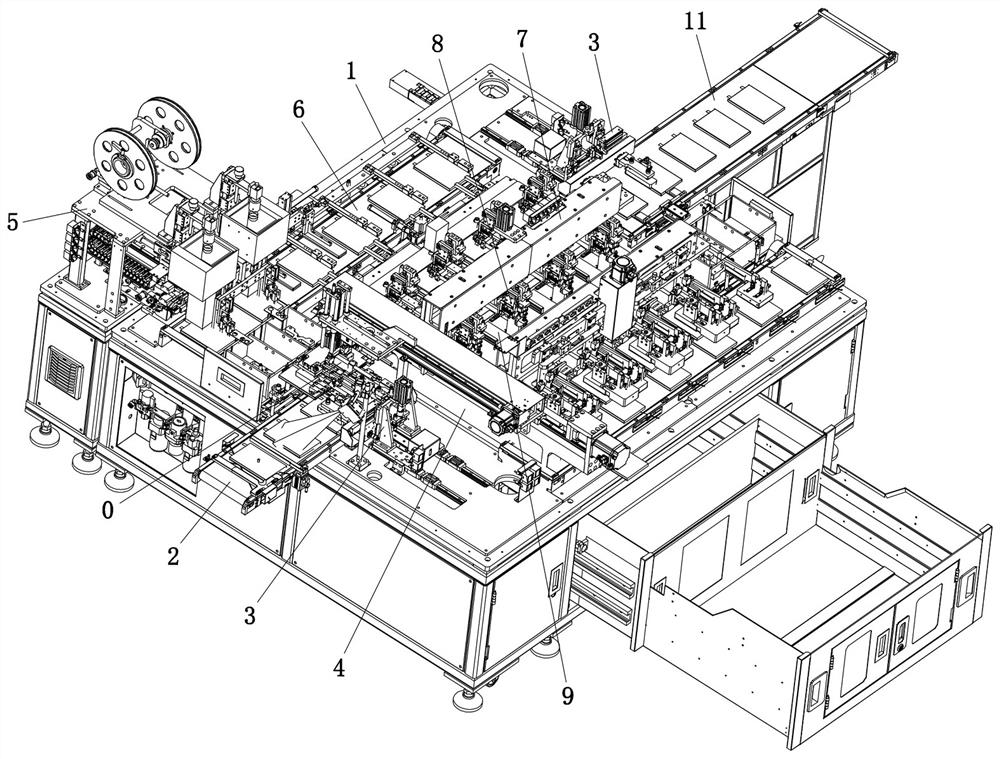

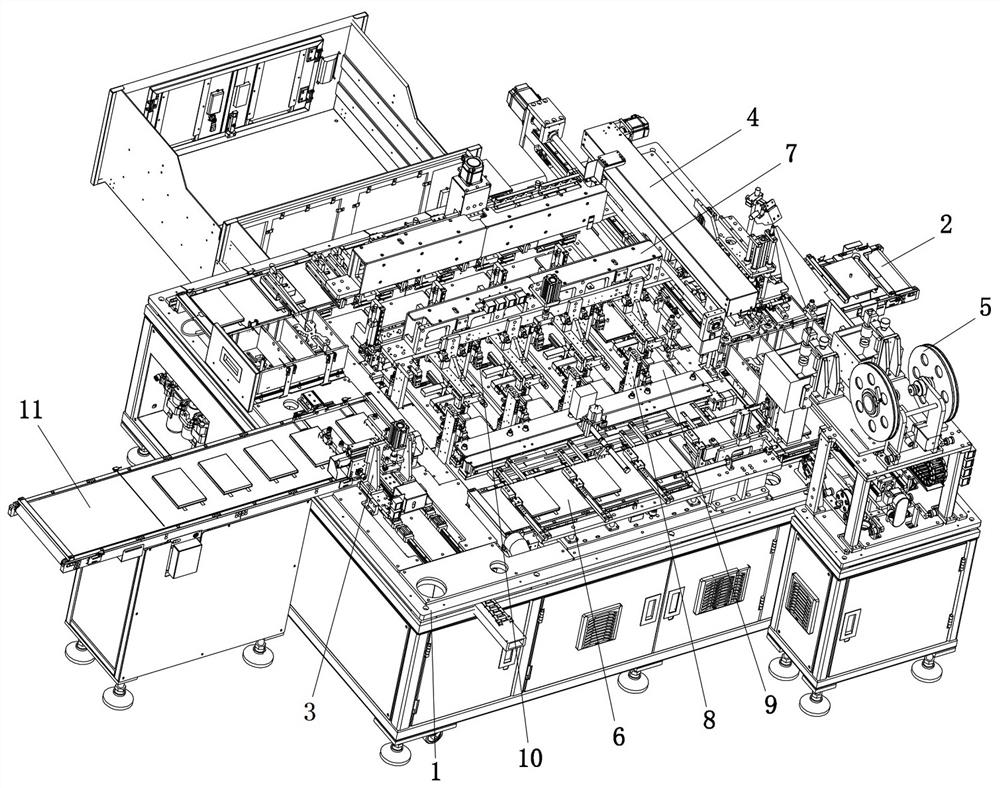

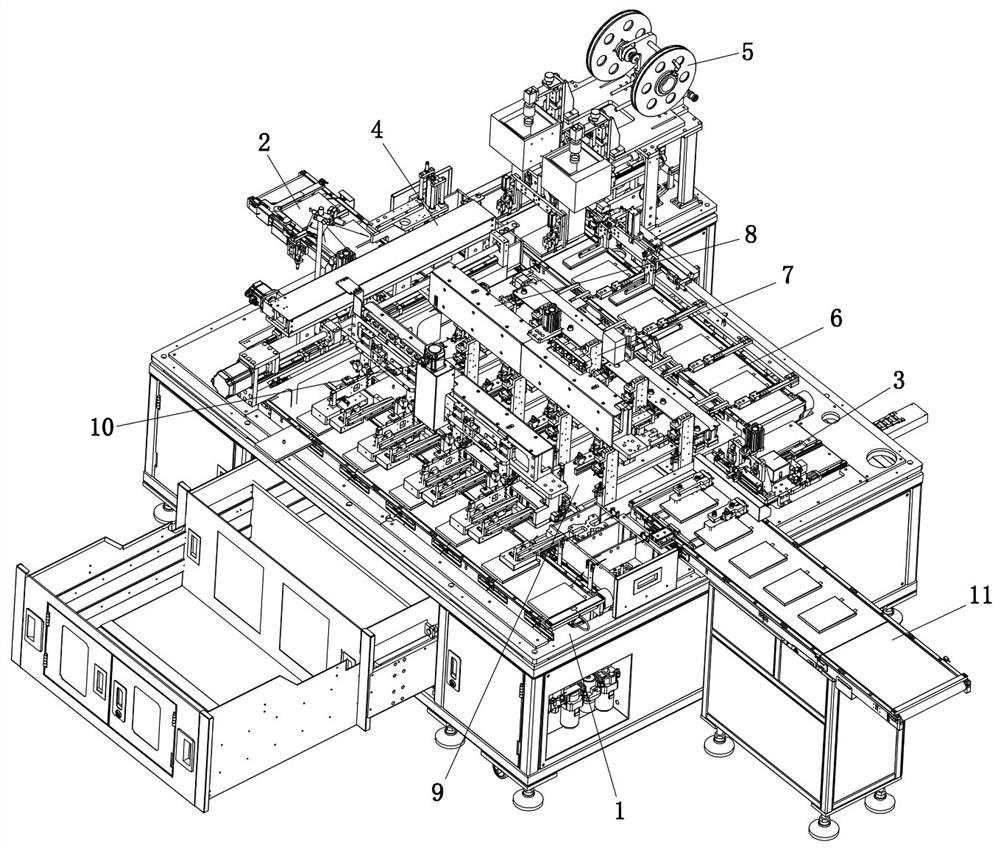

[0085] like Figure 1 to Figure 48As shown, the technical scheme adopted by the present invention is as follows: a fully automatic cell film tearing machine, comprising a feeding conveyor belt 2, a feeding mechanism 4, a pre-blowing mechanism 0, a transfer conveying mechanism 6, a transfer arm 7, a blowing Air and film tearing mechanism 8, film tearing platform 9, waste film clamping mechanism 10, transfer conveyor belt and unloading conveyor belt 11, wherein, the above-mentioned feeding conveyor belt 2 and unloading conveyor belt 11 are respectively arranged on the two sides of the machine 1 end; the above-mentioned transfer conveyor mechanism 6 and the transfer conveyor belt are arranged in parallel at intervals, and are located between the feeding conveyor belt 2 and the unloading conveyor belt 11; the above-mentioned feeding mechanism 4 straddles the upper feeding conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com