Photochromic pigment composition and preparation method thereof, plastic master batch and plastic workpiece

A technology for pigment composition and plastic workpieces, applied in the field of pigments, can solve problems such as poor color-dependent effects, and achieve the effects of high integrity, large particle size, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

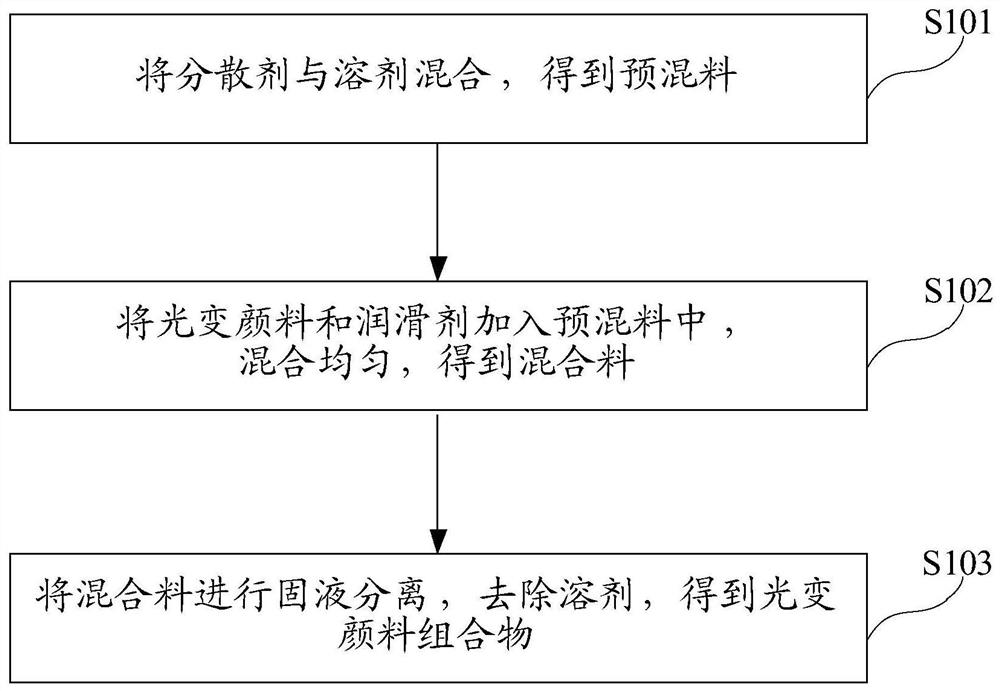

[0032] refer to figure 1 , figure 1 It is a schematic flow diagram of an embodiment of a preparation method of an optically variable pigment composition provided by the present application, including:

[0033] S101: mixing the dispersant with the solvent to obtain a premix;

[0034] S102: adding the optical variable pigment and the lubricant into the premix, and mixing uniformly to obtain a mixture;

[0035] S103: Separating the mixture into solid and liquid, removing the solvent, and obtaining an optically variable pigment composition.

[0036] Wherein, if the pigment auxiliary agent also includes a coupling agent, then in step 101, the coupling agent and the dispersant are added into the solvent and mixed uniformly to obtain a premix. It should be noted that, when mixing, the sequence of addition does not affect the properties of the final optically variable pigment composition. The preparation method also includes weighing each component according to the formulation amo...

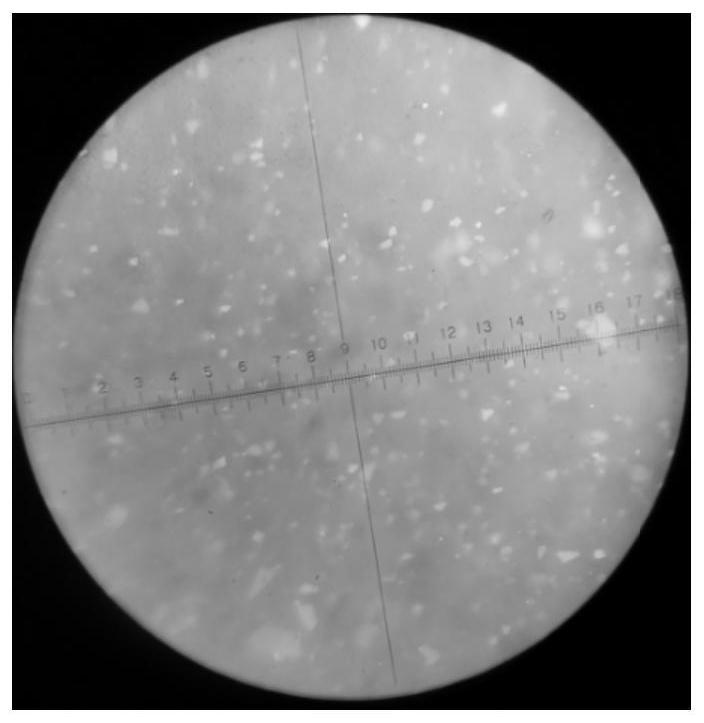

Embodiment 1

[0038] A kind of optically variable pigment composition, applied to the spray-free coating process, comprises the following components by parts by weight:

[0039] Light variable pigment 50 parts

[0040] Lubricant 10 parts

[0041] dispersant 3 parts

[0042] Among them, the optical variable pigment is the optical variable pigment of Huayang Optical, the particle size Dv50 is about 35 microns; the lubricant is methyl silicone oil; the dispersant is zinc stearate.

[0043] A preparation method of an optically variable pigment composition, comprising:

[0044] Add the dispersant to the ethanol solvent, stir for 5-10 minutes, and mix evenly to obtain a premix; add optical variable pigments and lubricants to the premix, and stir for 30 minutes to obtain a mixture; filter the mixture with suction , solid-liquid separation, solvent removal, and drying the filter cake to obtain optical variable pigment composition 1.

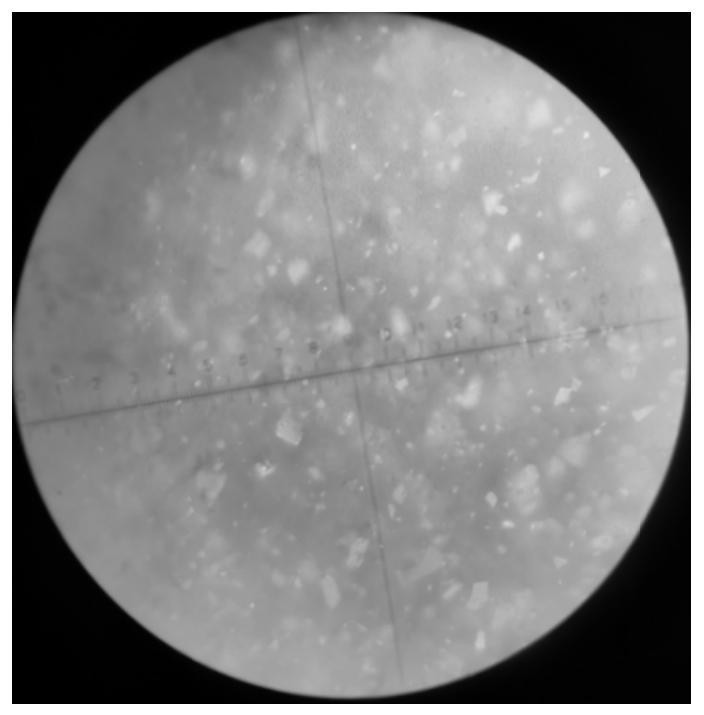

Embodiment 2

[0046] A kind of optically variable pigment composition, applied to the spray-free coating process, comprises the following components by parts by weight:

[0047] Light variable pigment 50 parts

[0048] Lubricant 5 parts

[0049] dispersant 3 parts

[0050] The optical variable pigment is the optical variable pigment of Huayang Optical, the particle size Dv50 is about 14 microns; the lubricant is methyl silicone oil; the dispersant is ethylene bis stearic acid amide EBS.

[0051] A preparation method of an optically variable pigment composition, comprising:

[0052] Add the dispersant to the ethanol solvent, stir for 5-10 minutes, and mix evenly to obtain a premix; add the pretreated optical variable pigment and lubricant to the premix, and stir for 30 minutes to obtain a mixture; mix the mixture performing suction filtration, solid-liquid separation, solvent removal, and drying the filter cake to obtain optically variable pigment composition II.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com