Biological fermentation condition detection device used during biological fermentation

A bio-fermentation and detection device technology, which is applied in the field of detection devices, can solve problems such as difficult detection of fermentation conditions, and achieve the effect of simplifying the operation process and making it easy to take out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

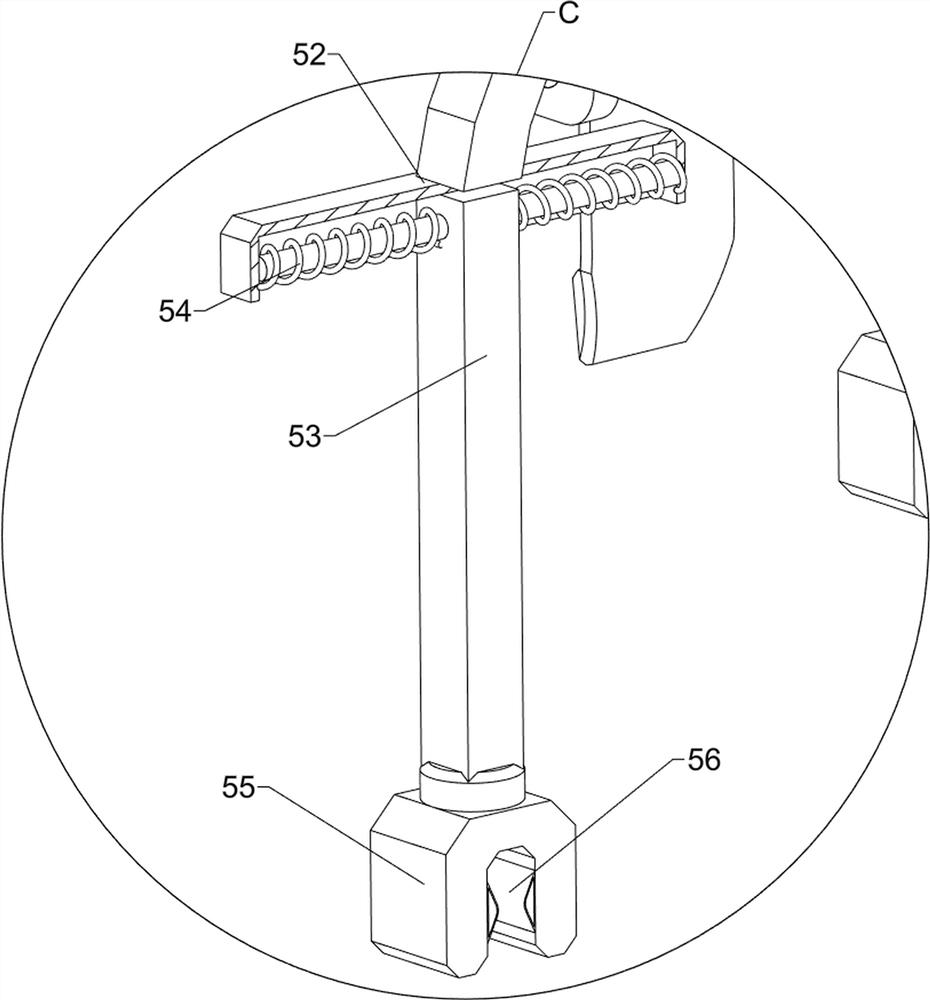

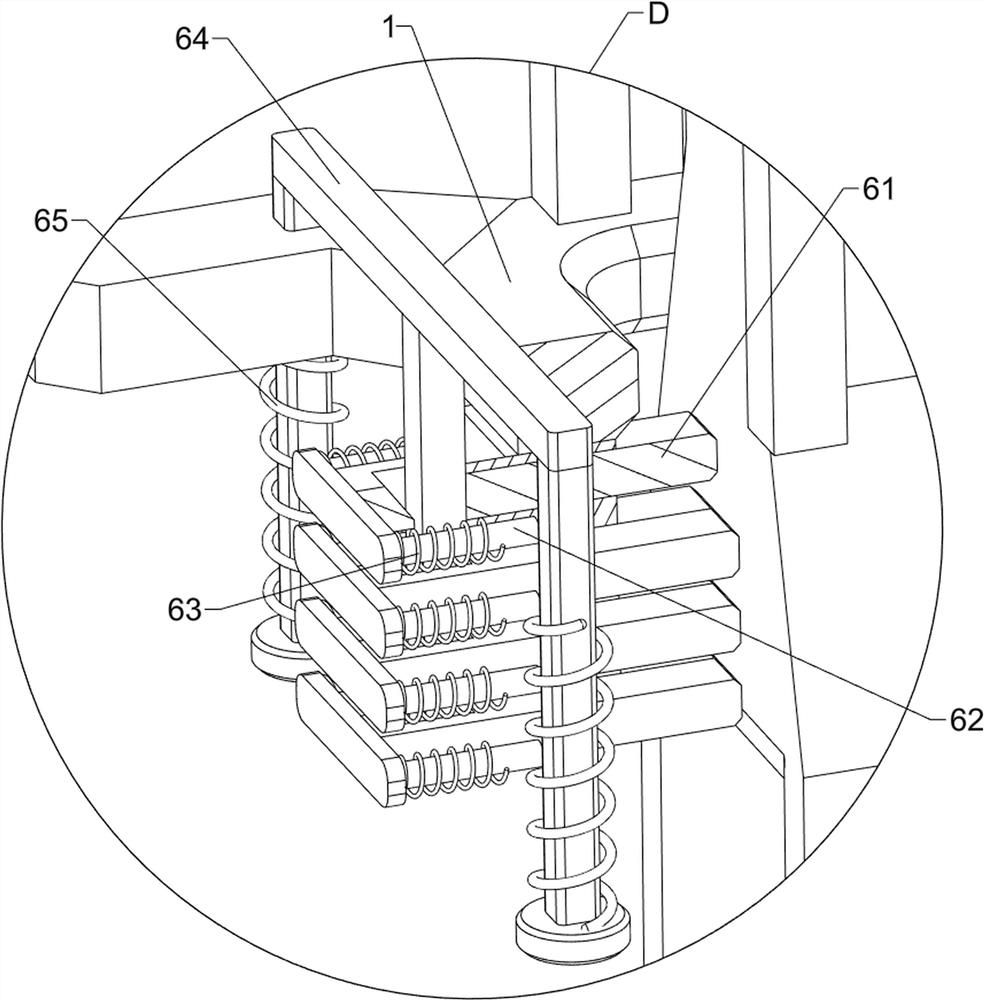

[0076] A device for detecting biological fermentation conditions during biological fermentation, such as figure 1 As shown, it includes a support plate 1, a pressing assembly 2, a retrieving assembly 3 and a clamping assembly 4. The supporting plate 1 is slidably connected to the pressing assembly 2, and the lower side of the pressing assembly 2 is connected to the retrieving assembly 3. A clamping assembly 4 is connected to the upper side of the support plate 1 .

[0077] When the device needs to be used, the user can place the device above the fermented product, push down the pressing assembly 2, and then continue to push down the pressing assembly 2, at this time the pressing assembly 2 is compressed to facilitate the removal of the fermented product , for the purpose of simplifying the operation process, the downward movement of the pressing component 2 drives the retrieving component 3 to move downward, and then makes the retrieving component 3 rotate forward, and the fer...

Embodiment 2

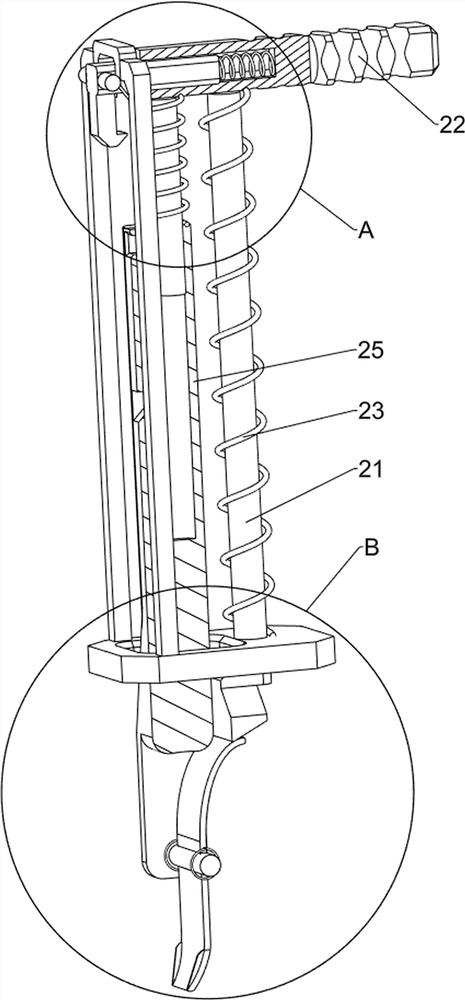

[0079] On the basis of Example 1, such as figure 2 and image 3 As shown, the pressing assembly 2 includes a first connecting rod 21, a handle 22, a first spring 23, a second connecting rod 24, a third connecting rod 25 and a second spring 26, and the support plate 1 is slidably connected with a second A connecting rod 21, the top of the first connecting rod 21 is connected with a handle 22, the first connecting rod 21 is wound with a first spring 23, the lower side of the handle 22 is connected with a second connecting rod 24, and the second connecting rod 24 slides A third connecting rod 25 is connected in a formula, the third connecting rod 25 passes through the support plate 1 , and the second connecting rod 24 is wound with a second spring 26 .

[0080] When the device needs to be used, the user can place the device above the fermented product, push the handle 22 downward, and the downward movement of the handle 22 drives the first connecting rod 21 to slide downward in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com