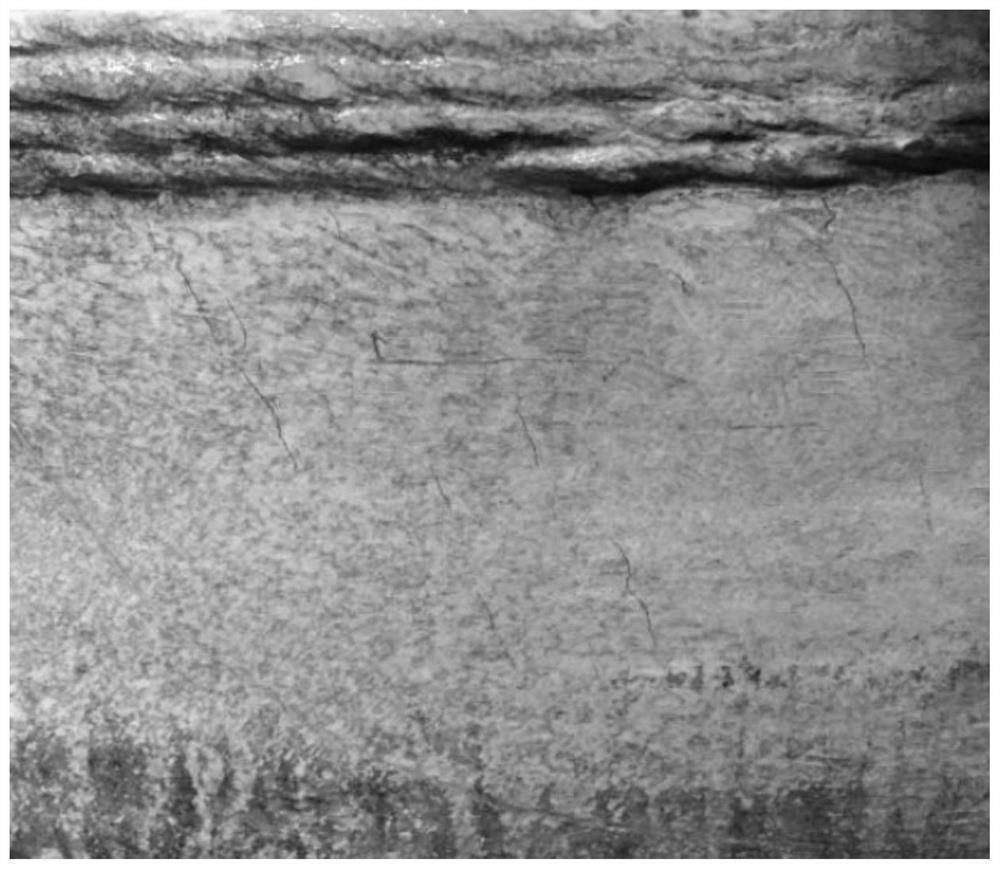

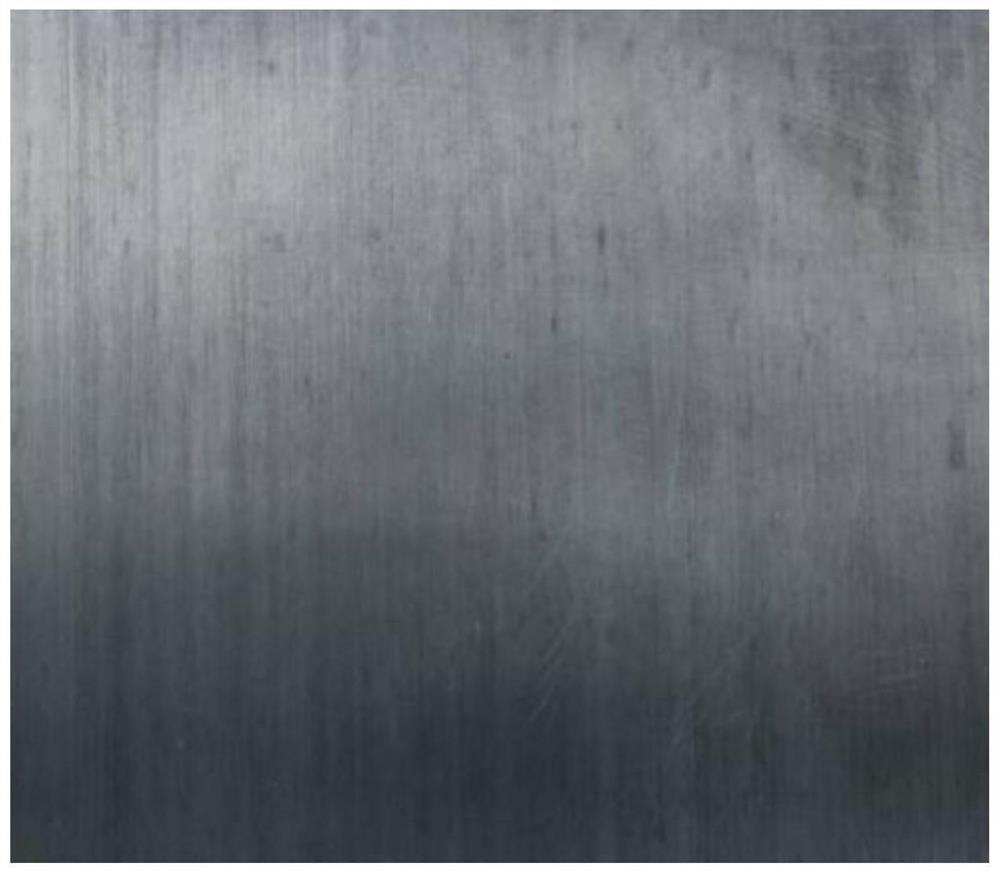

Production process for controlling surface cracks of micro-alloyed hot-rolled round steel

A technology of micro-alloying and surface cracking, which is applied in the field of iron and steel metallurgy and steel rolling, can solve the problems of billet quality decline, steel bar surface warping, and billet surface transverse cracks, etc., so as to improve the quality of billet products, reduce cracking tendency, Reduce the effect of surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A production process for controlling surface cracks of micro-alloyed hot-rolled round steel, comprising the following steps: continuously casting molten steel to obtain a billet, and sequentially reheating, rough rolling, finish rolling, normalizing, and cooling the billet; specifically :

[0029] In the steel slab, based on the total weight of the steel slab, the content of each component is: C 0.11-0.13wt%, Si0.10-0.20wt%, Mn 1.75-1.85wt%, V 0.03-0.06wt%, Mo 0.01-0.02wt%, N 0.01-0.013wt%, Ni 0.03-0.06wt%, and the rest are Fe and unavoidable impurities.

[0030] When reheating the steel slab, the steel slab was heated to 950°C.

[0031] The start rolling temperature of the rough rolling is 900°C, and the finish rolling temperature of the rough rolling is 870°C.

[0032] The start rolling temperature of the finish rolling is 800°C, and the finish rolling temperature is 750°C.

[0033] Normalizing heat treatment: Due to the use of microalloying, in order to ensure tha...

Embodiment 2

[0036] A production process for controlling surface cracks of micro-alloyed hot-rolled round steel, comprising the following steps: continuously casting molten steel to obtain a billet, and sequentially reheating, rough rolling, finish rolling, normalizing, and cooling the billet; specifically :

[0037] In the steel slab, based on the total weight of the steel slab, the content of each component is: C 0.11-0.13wt%, Si0.10-0.20wt%, Mn 1.75-1.85wt%, V 0.03-0.06wt%, Mo 0.01-0.02wt%, N 0.01-0.013wt%, Ni 0.03-0.06wt%, and the rest are Fe and unavoidable impurities.

[0038] When reheating the steel slab, the steel slab is heated to 1000°C.

[0039] The start rolling temperature of the rough rolling is 920°C, and the finish rolling temperature of the rough rolling is 880°C.

[0040] The start rolling temperature of the finish rolling is 820°C, and the finishing rolling temperature is 760°C.

[0041] Normalizing heat treatment: Due to the use of microalloying, in order to ensure ...

Embodiment 3

[0044] A production process for controlling surface cracks of micro-alloyed hot-rolled round steel, comprising the following steps: continuously casting molten steel to obtain a billet, and sequentially reheating, rough rolling, finish rolling, normalizing, and cooling the billet; specifically :

[0045] In the steel slab, based on the total weight of the steel slab, the content of each component is: C 0.11-0.13wt%, Si0.10-0.20wt%, Mn 1.75-1.85wt%, V 0.03-0.06wt%, Mo 0.01-0.02wt%, N 0.01-0.013wt%, Ni 0.03-0.06wt%, and the rest are Fe and unavoidable impurities.

[0046] When reheating the steel slab, the steel slab was heated to 1100°C.

[0047] The start rolling temperature of the rough rolling is 950°C, and the finish rolling temperature of the rough rolling is 890°C.

[0048] The start rolling temperature of the finish rolling is 850°C, and the finish rolling temperature is 770°C.

[0049] Normalizing heat treatment: Due to the use of microalloying, in order to ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com