Heat treatment method for GH4169 high-temperature alloy wire after cold deformation

A technology of GH4169 and high-temperature alloy wire, which is applied in the field of high-temperature alloy wire preparation, can solve the problems of low pass rate, unstable performance, immature cold processing technology of GH4169 alloy, etc., and achieve the goal of inhibiting grain growth and strengthening grain boundaries Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0019] Step 1: Obtain the cold-drawn state wire material of the GH4169 superalloy wire material by a cold-drawing method, and the cold-drawing deformation amount thereof is 40%.

[0020] Step 2. Place the cold-drawn wire material obtained in step 1 in a segmented vacuum heat treatment furnace for solution heat treatment, keep it at 1020°C for 20 minutes, then cool it down to 960°C at a cooling rate of 20°C / min, and keep it warm for 60 minutes ; and then filled with argon for air cooling; and during the solution heat treatment process, the vacuum degree -3 Pa.

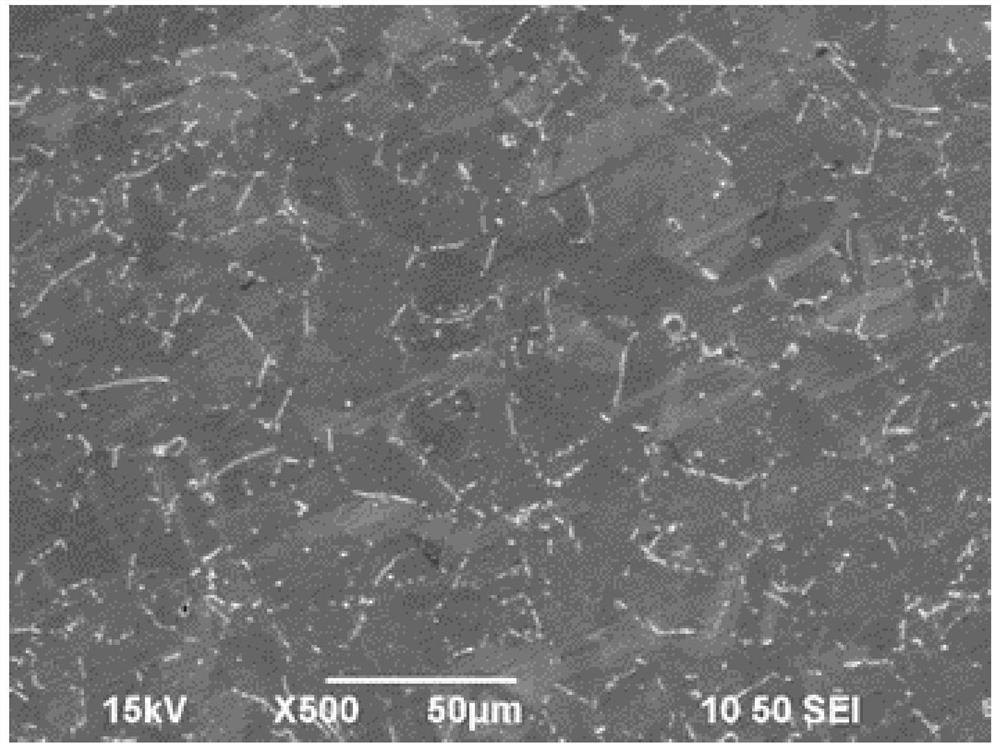

[0021] The microstructure of the alloy wire obtained after heat treatment is shown in figure 1 As shown, the alloy structure is uniform, recrystallized after deformation, and the precipitate phase is precipitated along the grain boundary, and the grain size is 8 grades. It meets the microstructure and performance requirements of GH4169 alloy for aerospace fasteners and spring wires.

specific Embodiment 2

[0023] Step 1: Obtain the cold-drawn state wire material of the GH4169 superalloy wire material by cold swaging method, and the deformation amount of the cold swaging method is 34%.

[0024] Step 2. Put the cold-drawn wire obtained in step 1 into a segmented vacuum heat treatment furnace for solution heat treatment, keep it at 1000°C for 10 minutes, then cool it down to 960°C at a cooling rate of 20°C / min, and keep it warm for 60 minutes , filled with argon for air cooling; and during the solution heat treatment process, the vacuum degree is -3 Pa.

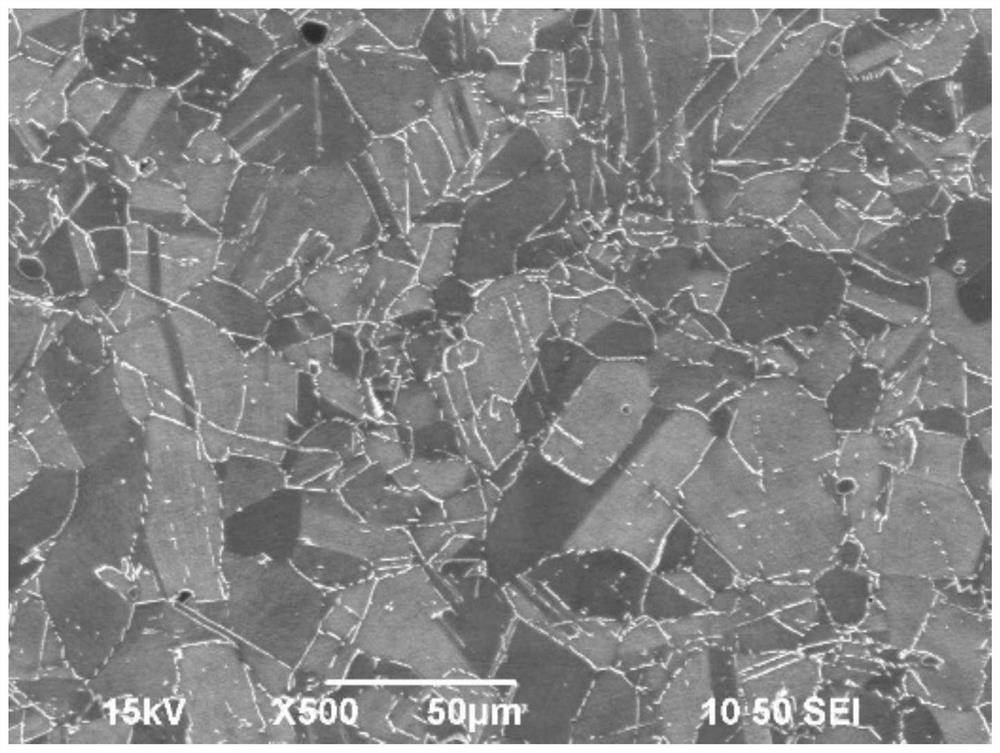

[0025] The microstructure of the alloy wire obtained after heat treatment is shown in figure 2 As shown, the alloy structure is uniform, and it is a recrystallized structure after deformation. The precipitate phase precipitates along the grain boundary, and the grain size is 7 grades. It meets the microstructure and performance requirements of GH4169 alloy for aerospace fasteners and spring wires.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com