One-bath dyeing-cleaning method for recycle polyester

A technology of recycled polyester and dyeing solution, which is applied in the field of textile printing and dyeing, can solve the problems of poor alkali resistance and damaged recycled polyester, and achieve ideal results, shorten the total water consumption, and shorten the total time-consuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

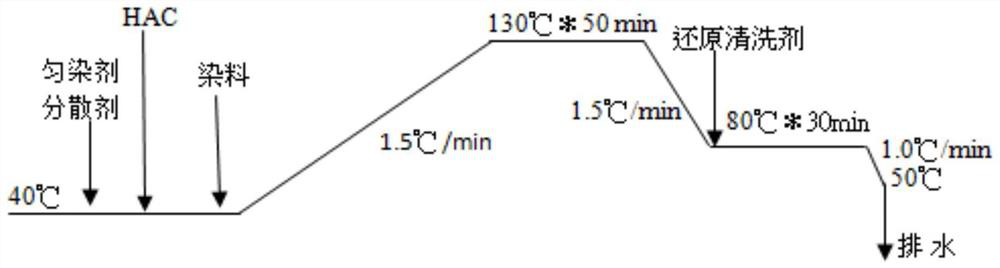

[0046] This embodiment provides a method for one-bath dyeing-cleaning of regenerated polyester, the method for one-bath dyeing-cleaning of regenerated polyester comprises the following steps:

[0047] (1) Put the regenerated polyester knitted fabric in the dye vat, soak it with water, add leveling agent K, dispersant P, acetic acid and dyes at 40°C to obtain a dyeing solution, and then raise the temperature at a constant rate of 1.5°C / min to 130°C, and finally insulated and dyed at a constant temperature of 130°C for 50 minutes; wherein, the bath ratio of the dyeing solution of the regenerated polyester knitted fabric is 1:10; the dyeing solution includes the following components by mass concentration: 4.1% (owf) Disperse Black ECT300%, 1.2% (owf) Disperse Dark Blue HGL200%, 0.7% (owf) Disperse Scarlet GS200%, 1.0g / L Dispersant P, 1.5g / L Leveling Agent K, 0.5g / L L of acetic acid;

[0048] (2) After the dyeing is completed, cool down to 80°C at a constant rate of 1.5°C / min, ad...

Embodiment 2

[0051] This embodiment provides a method for one-bath dyeing-cleaning of regenerated polyester, the method for one-bath dyeing-cleaning of regenerated polyester comprises the following steps:

[0052] (1) Put the regenerated polyester knitted fabric in the dye vat, soak it with water, add leveling agent K, dispersant P, acetic acid and dyes at 40°C to obtain a dyeing solution, and then raise the temperature at a constant rate of 1.5°C / min to 130°C, and finally insulated and dyed at a constant temperature of 130°C for 50 minutes; wherein, the liquor ratio of the dyeing solution of the regenerated polyester knitted fabric is 1:10; the dyeing solution includes the following components in terms of mass concentration: 3.0% (owf) Disperse Black ECT300%, 1.0% (owf) Disperse Dark Blue HGL200%, 1.0% (owf) Disperse Scarlet GS200%, 1.0g / L Dispersant P, 1.5g / L Leveling Agent K, 0.5g / L L of acetic acid;

[0053] (2) After the dyeing is completed, cool down to 80°C at a constant rate of 1....

Embodiment 3

[0056] This example provides a one-bath dyeing-cleaning method for regenerated polyester. The only difference from Example 1 is that in step (1), the temperature is raised to 130°C at a constant rate of 2.5°C / min, and other steps are the same as in Example 1. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com