An optimization method for the throttling window of the sleeve of the main feedwater regulating valve

A throttling window and optimization method technology, applied in multi-objective optimization, design optimization/simulation, valve device, etc., can solve the problem of affecting the control accuracy of the main feedwater regulating valve, increasing the friction between the valve core and the sleeve, and hindering the valve core. Movement and other issues, to achieve the effect of saving manpower and material resources, reducing unbalanced torque, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] This embodiment provides a method for optimizing the throttling window of the main feedwater regulating valve sleeve that can overcome the unbalanced moment of the spool. The implementation steps are as follows:

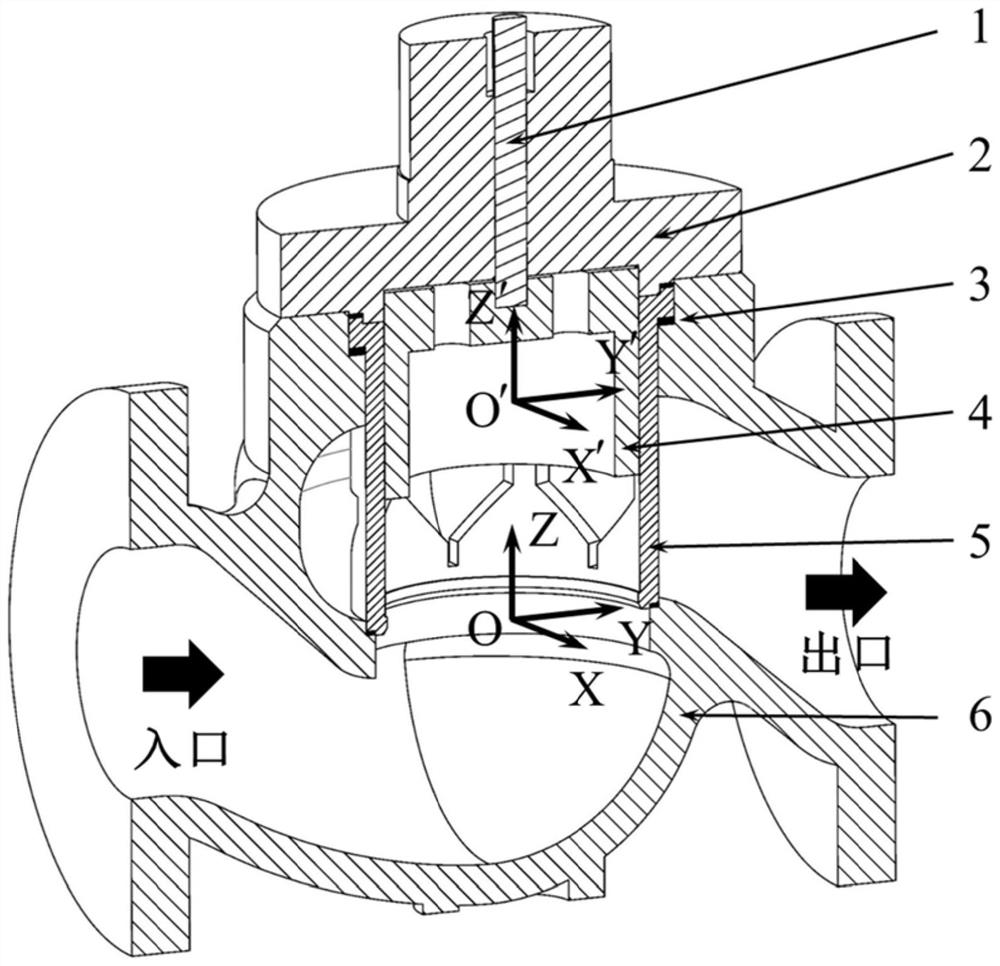

[0065] S1: According to the original main feedwater regulating valve design documents, construct the original three-dimensional structural model of the main feedwater regulating valve in the 3D modeling software. Such as figure 1 As shown, the original three-dimensional structure original model of the original main feedwater regulating valve includes valve stem 1, valve cover 2, gasket 3, valve core 4, sleeve 5 and valve body 6, which can clearly reflect the original main feedwater regulation The structure of each part of the valve.

[0066] The design documents include the composition information and operating condition information of the main feedwater regulating valve. The composition information includes the structure and size of the main feedwater regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com