Composite absorption structure

An absorbent structure and composite paper technology, applied in absorbent pads, medical science, bandages, etc., can solve the problems of poor absorber stability, poor air permeability, poor dryness, etc., and achieve fast absorption speed, good air permeability, and large absorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

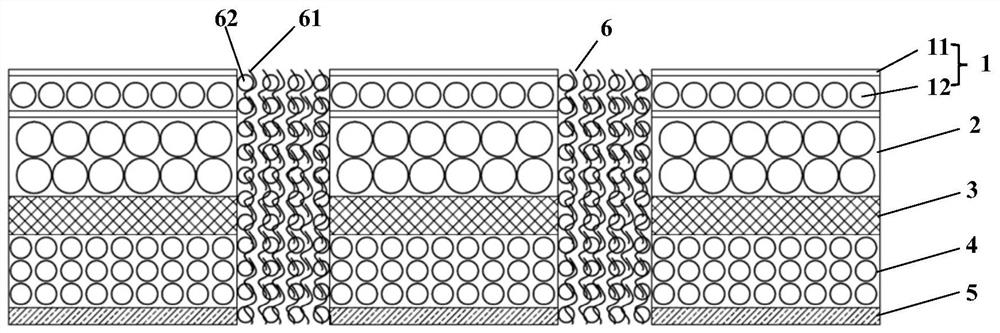

[0044] A composite absorbent structure, including a core structure, including from top to bottom:

[0045] Surface layer 1, the weight is 80g / m 2 , wherein the surface layer 1 is made of a layer of superabsorbent resin composite paper, which is formed by evenly distributing superabsorbent resin between two layers of base paper made of wood pulp through wet papermaking Super absorbent resin composite paper;

[0046] The first superabsorbent resin layer 2, the grammage is 150g / m 2 , containing superabsorbent resin particles of D 70 25-50 mesh;

[0047] Middle layer 3 (fluffy non-woven fabric layer), the grammage is 40g / m 2 ;

[0048] The second superabsorbent resin layer 4, the gram weight is 150g / m 2 , containing superabsorbent resin particles of D 80 35-80 mesh;

[0049] The bottom layer 5 (dust-free paper layer), the weight is 40g / m 2 ;

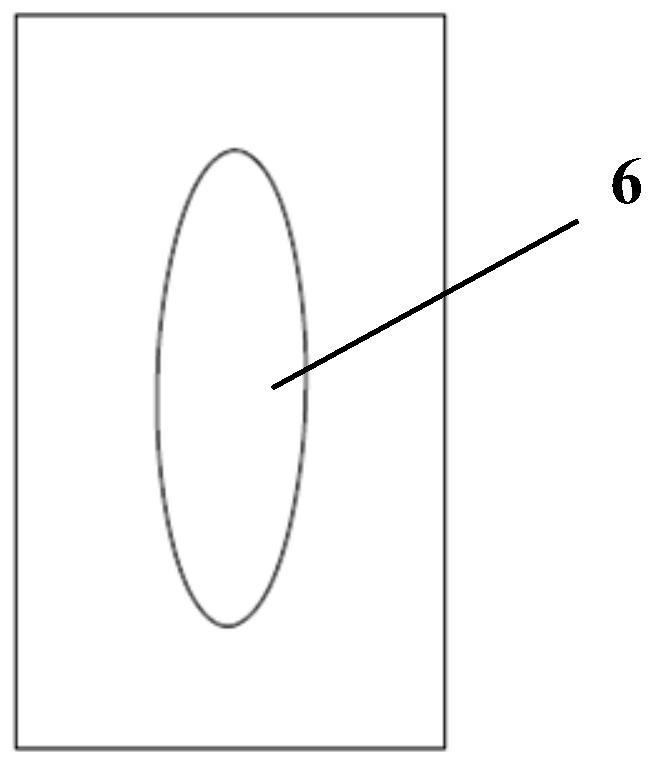

[0050] Such as figure 2 As shown, the core structure is provided with an oval diversion groove 6 penetrating from the surface l...

Embodiment 2

[0052] A composite absorbent structure comprising a core structure such as figure 1 As shown, from top to bottom include:

[0053] Surface layer 1, the grammage is 100g / m 2 , wherein the surface layer 1 is made of a layer of superabsorbent resin composite paper, which is formed by evenly distributing superabsorbent resin between two layers of base paper made of wood pulp through wet papermaking Super absorbent resin composite paper;

[0054] The first superabsorbent resin layer 2, the grammage is 160g / m 2 , containing superabsorbent resin particles of D 70 25-50 mesh;

[0055] Middle layer 3 (fluffy non-woven fabric layer), the grammage is 35g / m 2 ;

[0056] The second superabsorbent resin layer 4, the grammage is 130g / m 2 , containing superabsorbent resin particles of D 80 35-80 mesh;

[0057] Bottom layer 5 (spunlace non-woven fabric layer), the grammage is 28g / m 2 ;

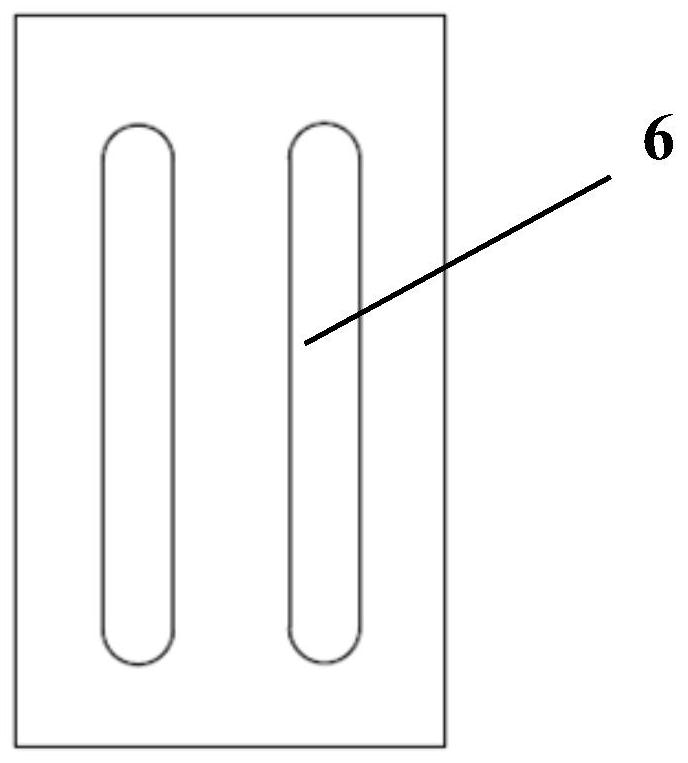

[0058] Such as image 3 As shown, the core structure is provided with two elongated guide groov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com