A kind of peelable protective film and its composition formula

A composition and protective film technology, applied in the field of peelable protective film and its composition formulation, can solve the problems of no environmental protection, time-consuming and laborious removal of residual glue, peeling, etc., and achieve the effects of excellent adhesion and good surface dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

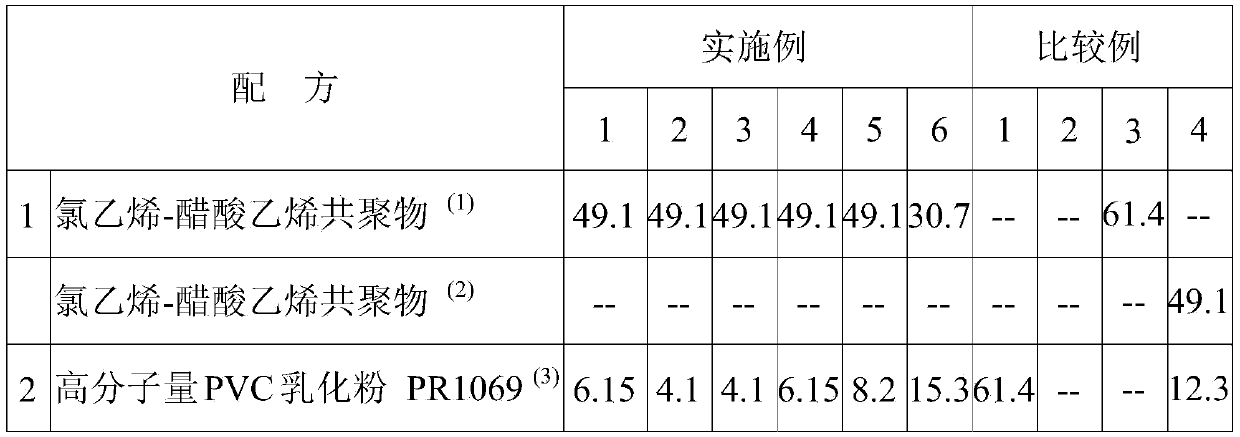

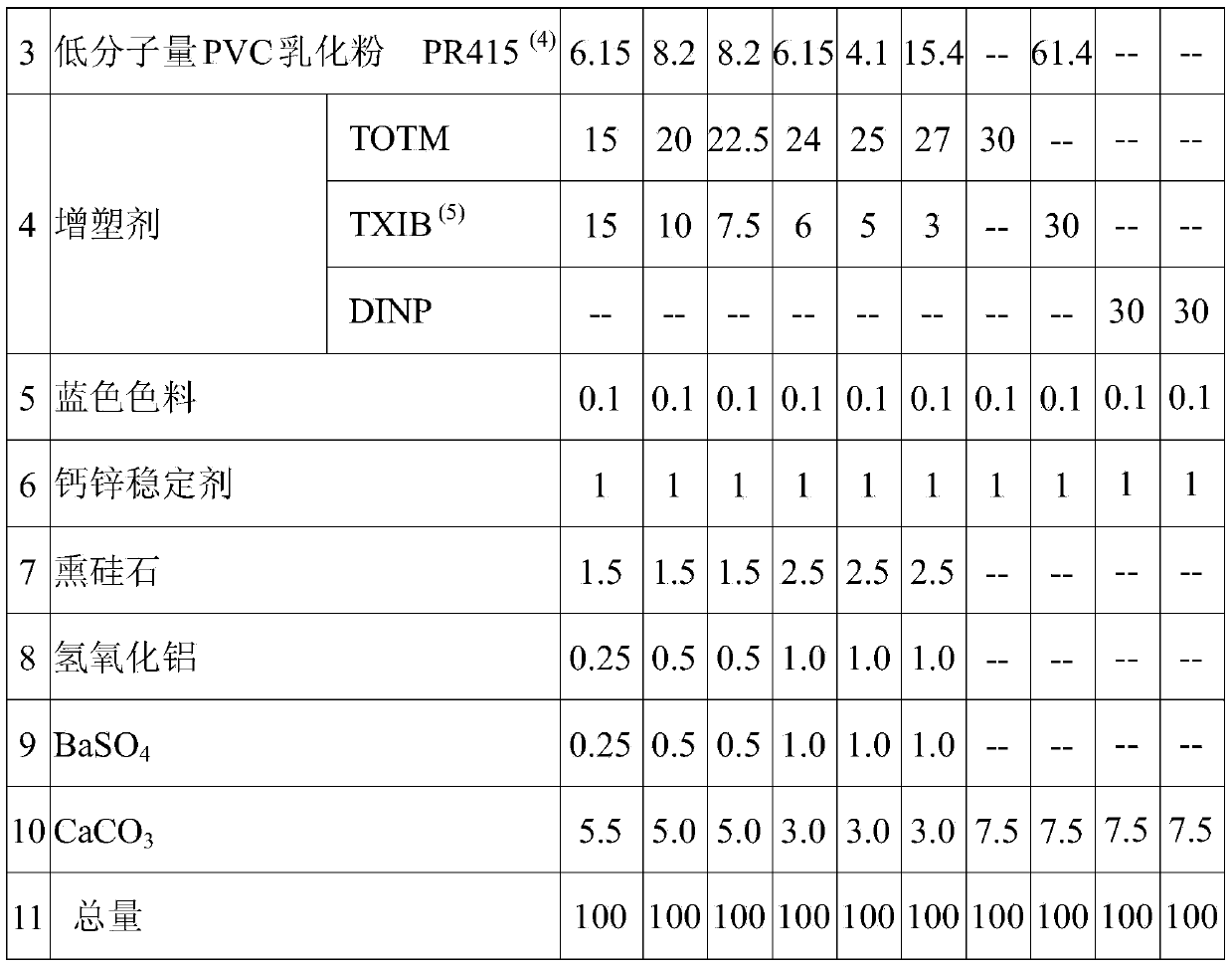

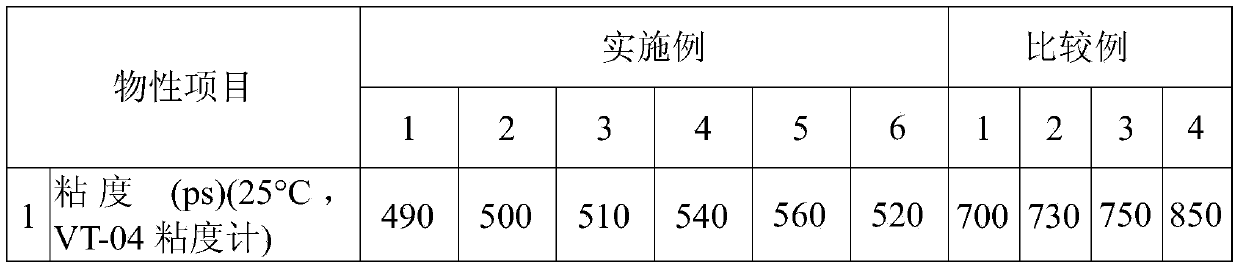

[0094] According to the formulation in Table 1 (numbers are parts by weight), the strippable compositions of Examples 1-6 were respectively prepared, and then their physical properties were measured respectively, including viscosity, TI value, viscosity stability and sag resistance. The measurement results were as follows Table 2 shows.

[0095]The prepared strippable compositions were prepared into strippable protective films through coating processing, and then their properties were measured, including baking resistance, peelability, adhesion and peel strength. The measurement results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com