LED curing high-filling vacuum spraying primer and preparation method thereof

A vacuum spraying and primer technology, applied in primers, coatings, polyester coatings, etc., can solve problems such as increasing the cost of primers, poor filling performance, and affecting the production efficiency of small workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

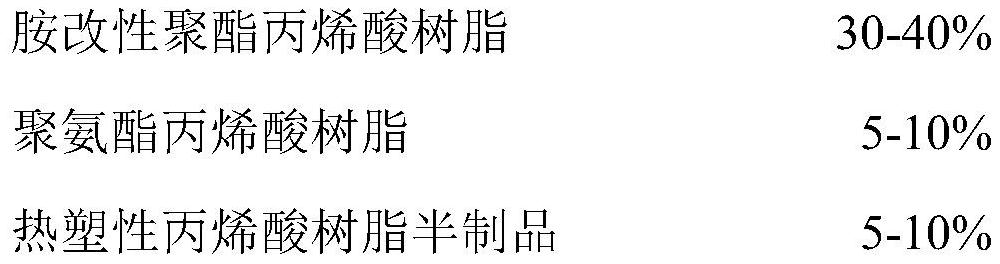

[0030] A kind of LED curing high filling vacuum spraying primer of the present embodiment, it is made up of the raw material of following percentage by weight:

[0031]

[0032] Wherein, the preparation method of the thermoplastic acrylic resin semi-finished product is: mix HDDA and thermoplastic acrylic solid resin in a mass ratio of 1.5:1, and then stir at 800 rpm for 40 minutes.

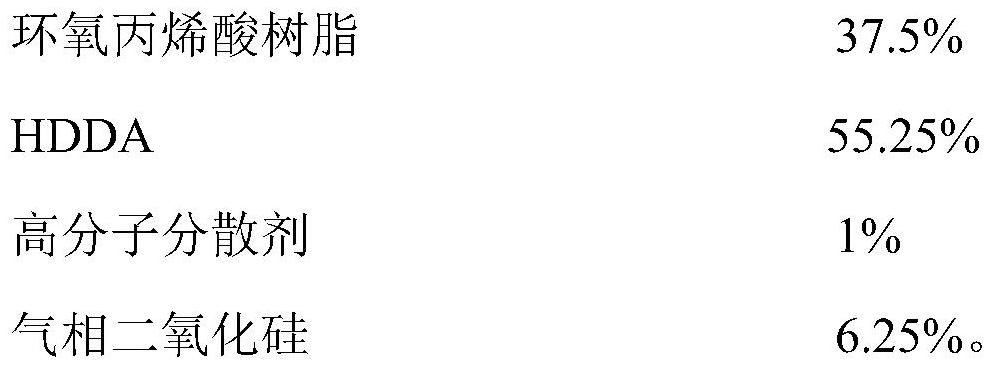

[0033] Wherein, the fumed silica semi-finished product is made of the following raw materials in weight percentages of raw materials:

[0034]

[0035] Wherein, the preparation method of the fumed silica semi-finished product is: first mix the epoxy acrylic resin, HDDA and polymer dispersant, stir at 600rpm for 10 minutes, then add fumed silica, and stir at 800rpm After 40 minutes, use a horizontal sand mill to grind to a fineness of less than 15 microns to obtain a fumed silica semi-finished product.

[0036] Wherein, the polymer dispersant is a polymer dispersant commonly used in the tech...

Embodiment 2

[0044] A kind of LED curing high filling vacuum spraying primer of the present embodiment, it is made up of the raw material of following percentage by weight:

[0045]

[0046]

[0047] Among them, the thermoplastic acrylic resin semi-finished product, fumed silica semi-finished product, polymer dispersant, wetting and dispersing agent and polymer resin particle powder are as shown in Example 1.

[0048] Referring to the preparation method of a LED-cured high-fill vacuum spray primer in Example 1, the LED-curable high-fill vacuum spray primer of this embodiment was obtained.

Embodiment 3

[0050] A kind of LED curing high filling vacuum spraying primer of the present embodiment, it is made up of the raw material of following percentage by weight:

[0051]

[0052] Among them, the thermoplastic acrylic resin semi-finished product, fumed silica semi-finished product, polymer dispersant, wetting and dispersing agent and polymer resin particle powder are as shown in Example 1.

[0053] Referring to the preparation method of a LED-cured high-fill vacuum spray primer in Example 1, the LED-curable high-fill vacuum spray primer of this embodiment was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com