Conductive water-based white primer for plastic base material and preparation method thereof

A white primer, water-based technology, applied in the direction of primer, conductive paint, coating, etc., can solve the problems of low utilization rate and non-conductive properties of the back paint, and achieve the effect of reducing static electricity, good adhesion, and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of preparation that is used for the conductive water-based white primer of plastic substrate, specifically comprises the following steps:

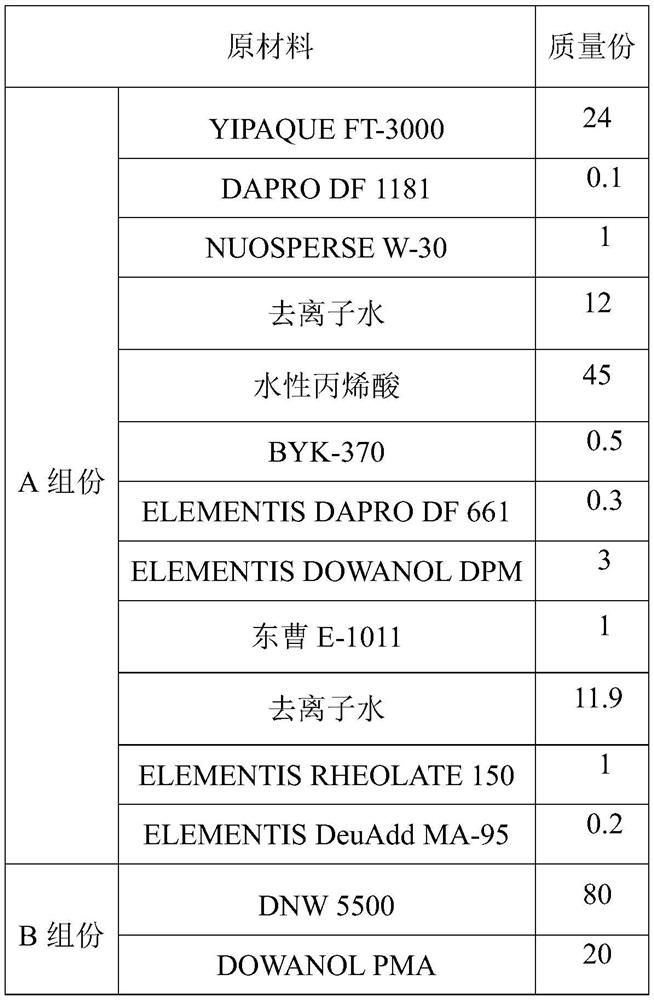

[0047] Weighing of components:

[0048]

[0049] Preparation of component A:

[0050] (1) Add 7.5 parts of methyl methacrylate and 8 parts of butyl acrylate to the kettle, and raise the temperature after mixing; then add 6 parts of butyl methacrylate, 14 parts of acrylic acid-β- Hydroxypropyl ester, 4 parts of styrene, 4 parts of acrylonitrile, 5 parts of methacrylic acid, 1.5 parts of glycidyl methacrylate, 0.5 parts of mercaptoethanol, 0.7 parts of azobisisobutyronitrile, 9.5 parts of n-butanol, 3.5 parts part of ethanol, continue to react, then lower the temperature; add 5.3 parts of dimethylethanolamine under full stirring, then add 30.5 parts of deionized water under high shear, finally obtain water-based acrylic resin;

[0051] (2) Calculate the amount required for each material of A according to the amount of disp...

Embodiment 2

[0061] A conductive water-based white primer for plastic substrates, the preparation steps of which are as follows:

[0062] (1) Preparation of water-based acrylic resin: Add 7.5 parts of methyl methacrylate and 8 parts of butyl acrylate into the reactor, and raise the temperature to 115°C after mixing; then add 6 parts of methacrylic acid into the reactor Butyl ester, 14 parts of β-hydroxypropyl acrylate, 4 parts of styrene, 4 parts of acrylonitrile, 5 parts of methacrylic acid, 1.5 parts of glycidyl methacrylate, 0.5 parts of mercaptoethanol, 0.7 parts of azobisisobutyl Nitrile, 9.5 parts of n-butanol, 3.5 parts of ethanol, continue to react for 8 hours, then lower the temperature to 65°C; fully stir at 300 rpm, add 5.3 parts of dimethylethanolamine, and then add 30.5 parts of deionized water under high shear at 1000 rpm , finally get water-based acrylic resin;

[0063] (2) Preparation of component A: weigh 20 parts of YIPAQUE FT-3000, 10.3 parts of ELEMENTIS DAPRO DF 11810...

Embodiment 3

[0069] A conductive water-based white primer for plastic substrates, the preparation steps of which are as follows:

[0070] (1) Preparation of water-based acrylic resin: add 7.5 parts of methyl methacrylate and 8 parts of butyl acrylate into the reactor, and raise the temperature to 110°C after mixing; then add 6 parts of methacrylic acid into the reactor Butyl ester, 14 parts of β-hydroxypropyl acrylate, 4 parts of styrene, 4 parts of acrylonitrile, 5 parts of methacrylic acid, 1.5 parts of glycidyl methacrylate, 0.5 parts of mercaptoethanol, 0.7 parts of azobisisobutyl Nitrile, 9.5 parts of n-butanol, 3.5 parts of ethanol, continue to react for 12 hours, then cool down to 60°C; fully stir at 400rpm, add 5.3 parts of dimethylethanolamine, and then add 30.5 parts of deionized water under high shear at 900rpm , finally get water-based acrylic resin;

[0071] (2) Preparation of component A: Weigh 25 parts of YIPAQUE FT-3000, 10.2 parts of ELEMENTIS DAPRO DF 11810, 2 parts of N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com