Strong stirring equipment for high-temperature binder for refractory material

A technology of high-temperature binder and strong stirring, which is applied to mixer accessories, mixers with rotating stirring devices, dissolution, etc., can solve problems such as insufficient stirring, slow finished product efficiency, and difficult cleaning of devices, and achieve uniform heating and increased Efficiency, sufficient stirring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

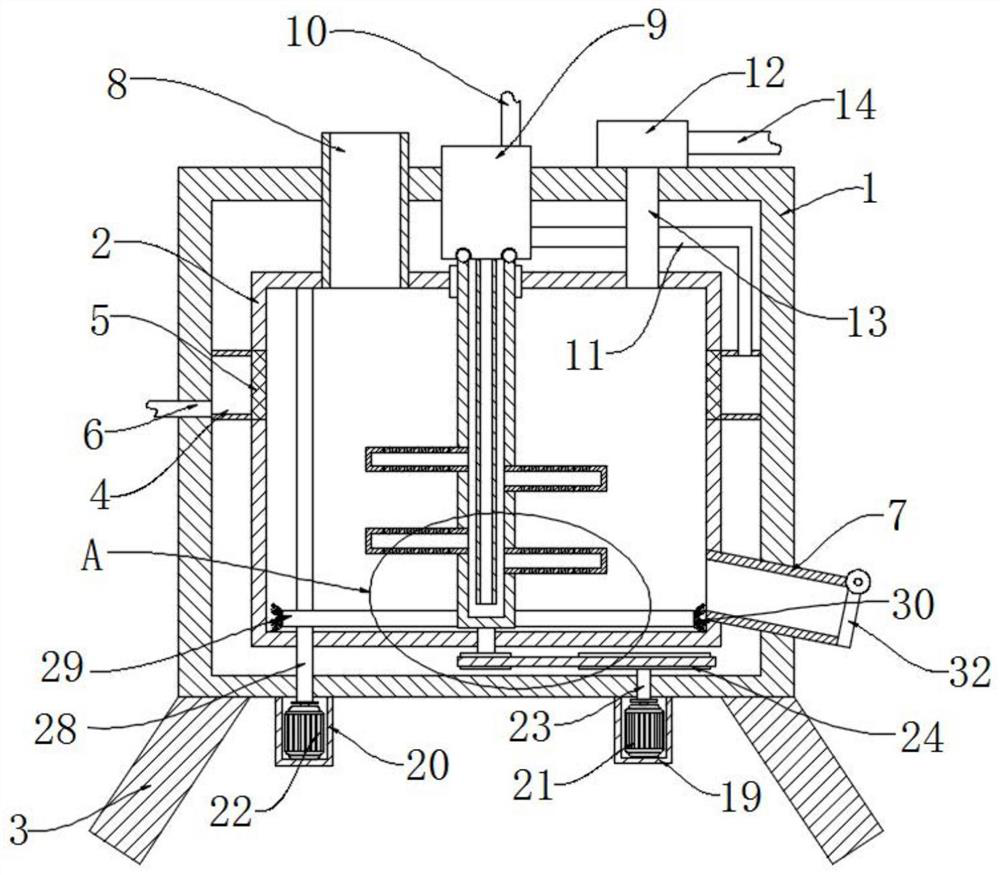

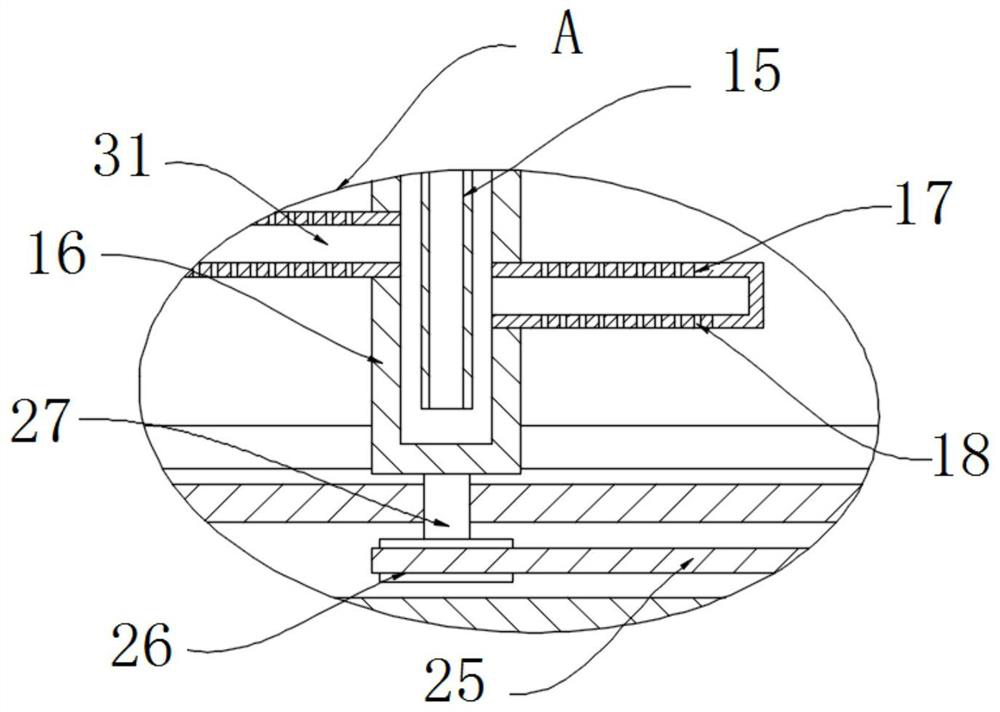

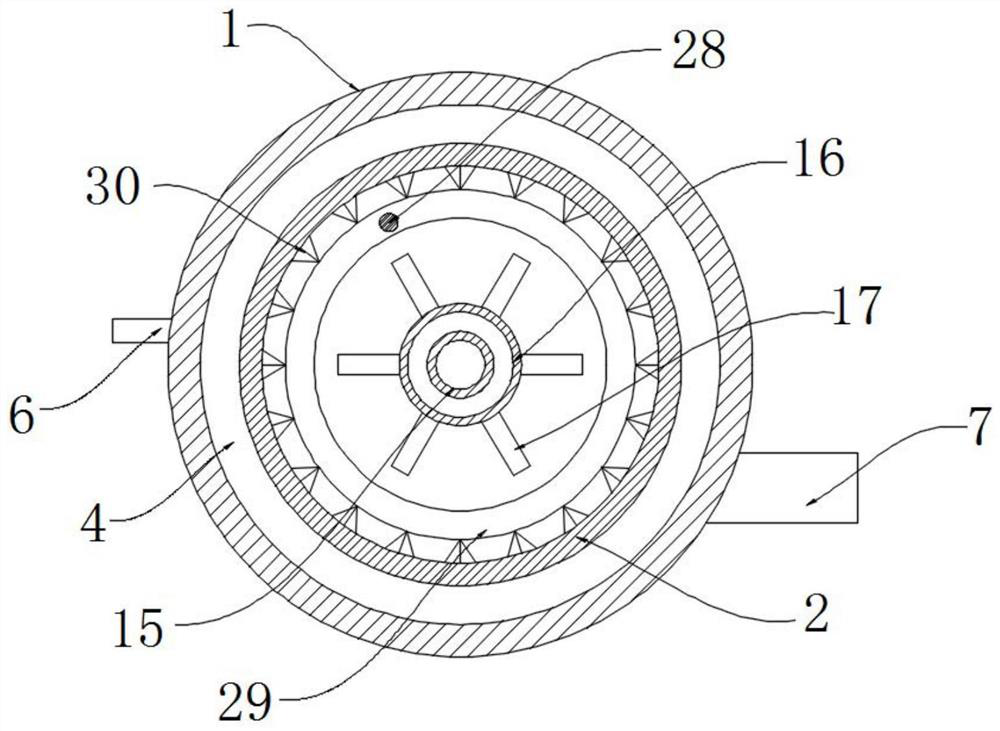

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Apparently, the described embodiments are only some, not all, embodiments of the present invention.

[0027] refer to Figure 1-4 , a high-temperature binder strong stirring equipment for refractory materials, including a main box 1 and an auxiliary box 2, the bottom of the main box 1 is welded with a support column 3, and the main box 1 and the auxiliary box 2 are welded together by a welding machine There is a cold air box 4, and an elastic sleeve 5 is fixedly arranged at the connection between the auxiliary box body 2 and the cold air box 4. The elastic sleeve 5 is in the shape of a ring and matches with the auxiliary box body 2. The cold air box 4 is in common with the side wall of the main box body 1. The cold air outlet pipe 6 is glued together, the cold air out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com