Non-Newtonian fluid valve blockage cleaning mechanism and application thereof to shield tunneling machine

A non-Newtonian fluid and valve technology, applied in cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve the problems of valve seat closing difficulties, high maintenance/repair costs, seal leakage, etc., and achieve simple installation and operation Convenience, good dredging effect and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

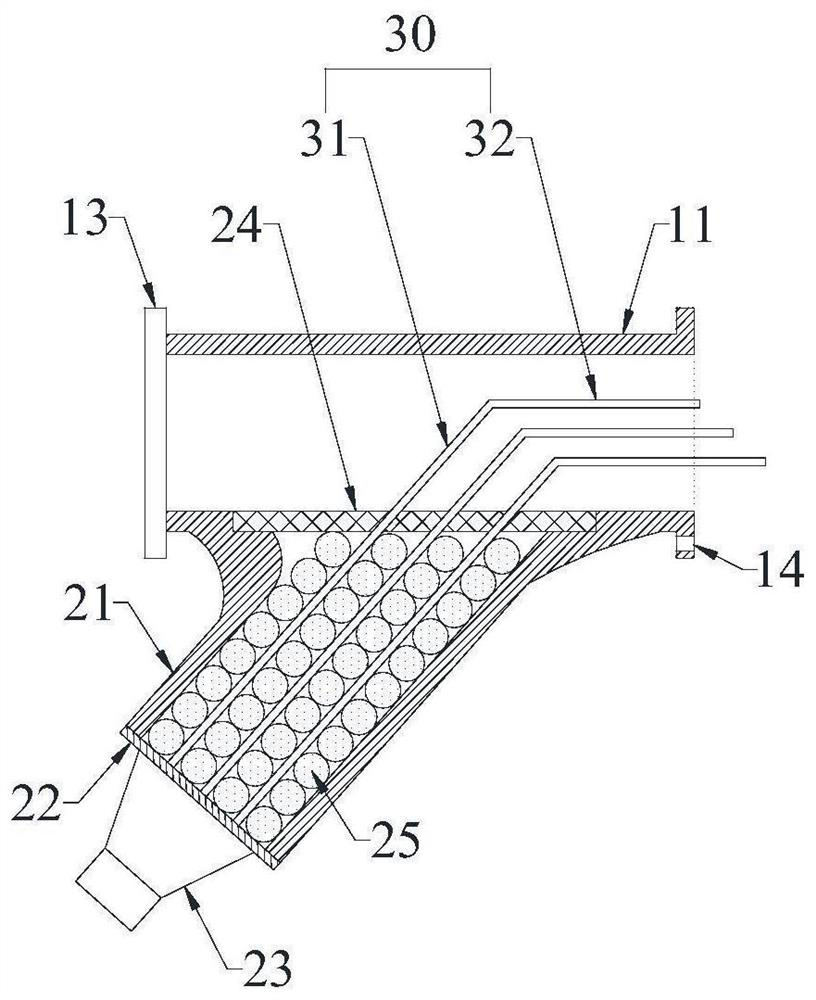

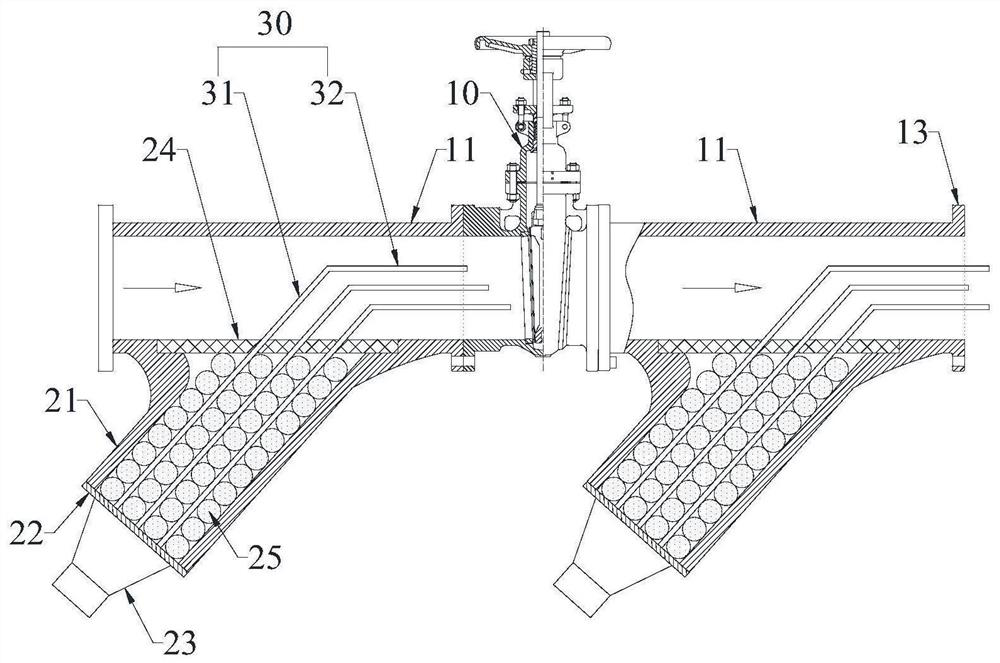

[0035] like figure 1 As shown, the non-Newtonian fluid valve blockage cleaning mechanism includes a circular tubular straight pipe body 11, an inclined pipe 21 arranged obliquely, a vibrating plate 22 installed at the tail end of the inclined pipe 21, and an ultrasonic wave for driving the vibrating plate 22 to vibrate. The transducer 23, a plurality of vibrating rods 30 distributed in an array, the two ends of the straight pipe body 11 are respectively fixed with flanges 13, and the flange 13 is connected with the ends of the straight pipe body 11 as a whole; The side wall of the straight pipe body 11 is provided with a mounting hole communicating with the head end of the inclined pipe 21, the edge of the vibrating plate 22 is sealed and connected with the tail end of the inclined pipe 21, and the ultrasonic transducer 23 is fixedly installed in the vibrating The outside of the plate 22; the vibrating rod 30 includes an inclined bar section 31 arranged parallel to the axial d...

Embodiment 2

[0049] Among them, in order to further improve the sealing performance, such as Figure 11 As shown, the outer side of the flange 13 is provided with an annular receiving groove 15, and the cross section of the receiving groove 15 is an arc-shaped structure. An O-ring seal is installed at the receiving groove 15 to improve sealing.

[0050] The installation and operation between the non-Newtonian fluid valve blockage cleaning mechanism and the existing mud valve is simple and convenient, without any change to the structure of the existing mud valve, so that it can meet the relevant current national standards, and the implementation effect is good.

Embodiment 3

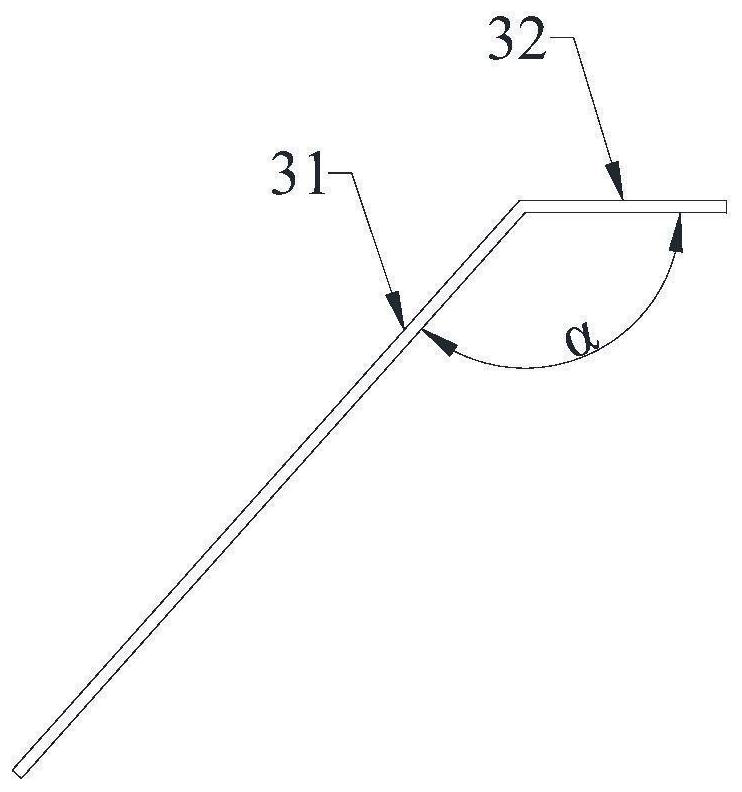

[0052] Based on Example 2, such as figure 2 As shown, the included angle between the longitudinal direction of the oblique bar section 31 and the longitudinal direction of the horizontal bar section 32 is α, 120°≤α≤135°. The included angle between the axis of the inclined tube 21 and the axis of the straight tube body 11 is also defined synchronously. After many tests, it is found that the above angle range can minimize the axial resistance inside the straight pipe body 11 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com