U-shaped rib assembling and positioning device

A positioning device, U-shaped technology, applied in auxiliary devices, auxiliary welding equipment, welding equipment, etc., can solve the problems of difficult precise control of the assembly gap between U-shaped ribs and bridge decks, fatigue cracks in plate units, etc., and eliminate the root causes of cracks , the gap is uniform, and the effect of improving the overall anti-fatigue ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

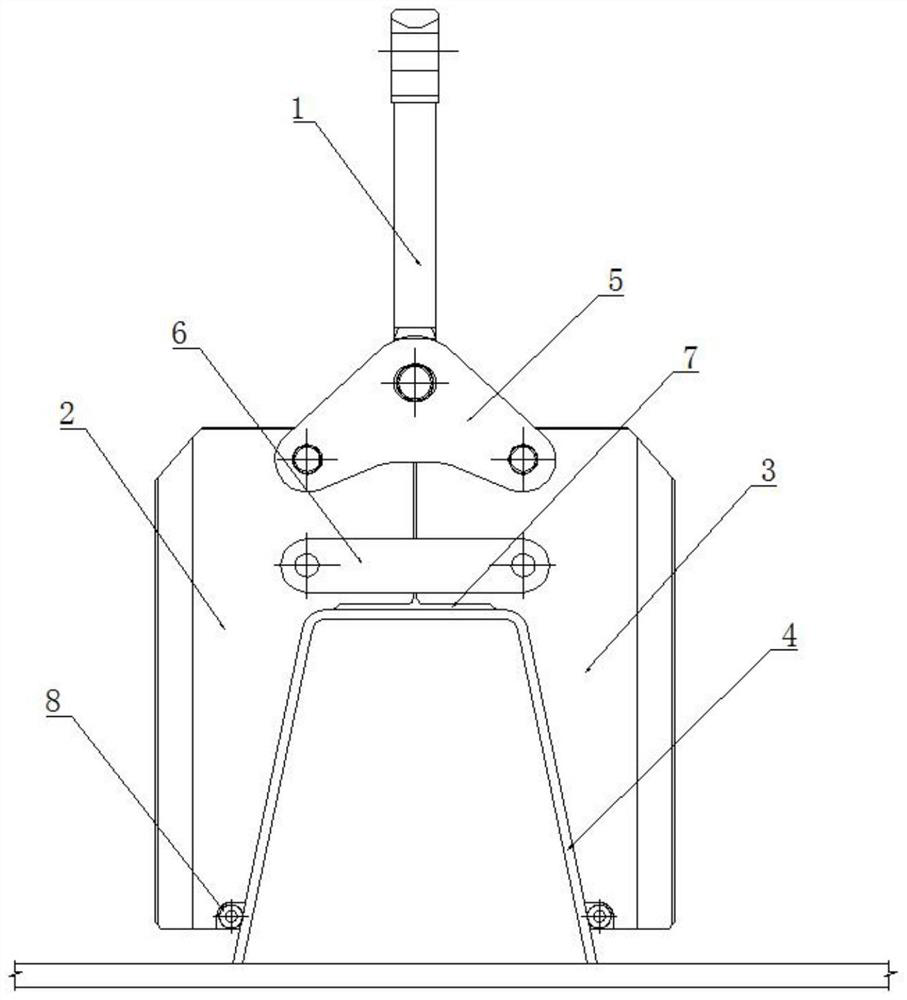

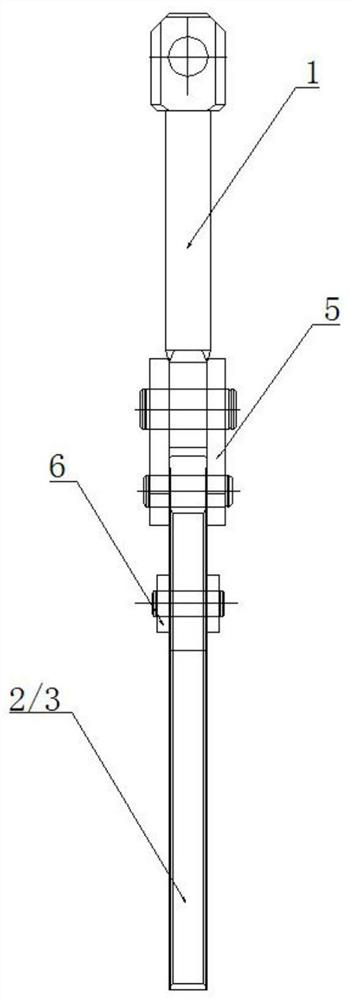

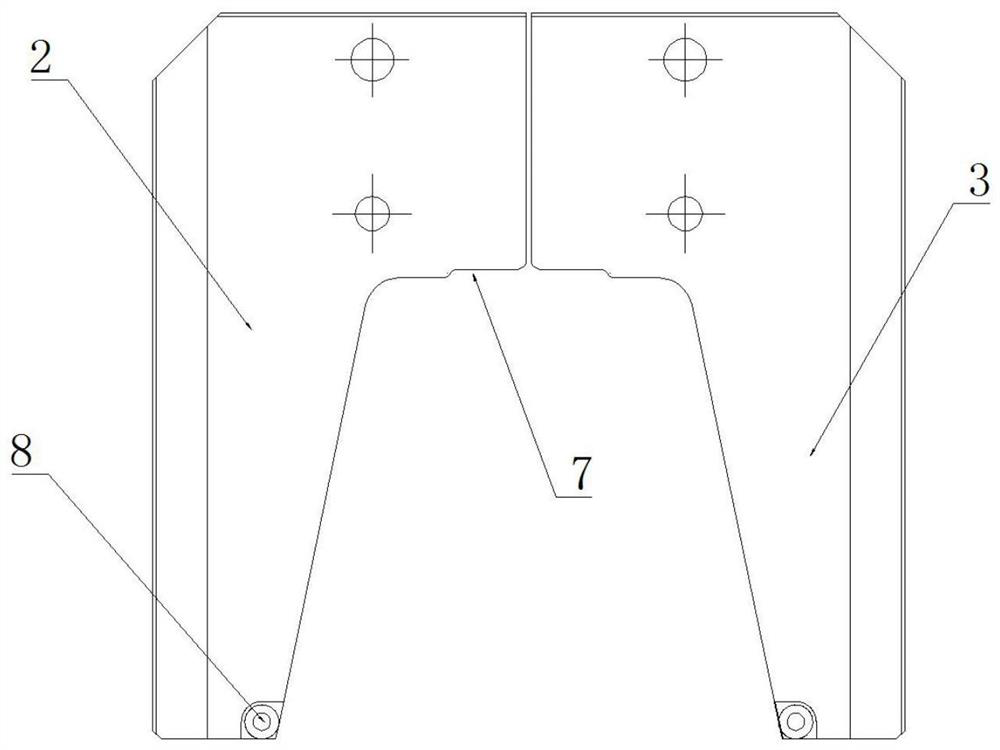

[0020] A U-shaped rib assembly and positioning device, mainly composed of a connecting rod 1 connected to a pressure mechanism, and a first pressing plate 2 and a second pressing plate 3 symmetrically hinged on the connecting rod, the first pressing plate 2 and the second pressing plate The second pressing plate 3 is a "7" shape that fits one side of the U-shaped rib, corresponding to the left and right sides of the U-shaped rib 4, as figure 1 shown.

[0021] When the pressure mechanism exerts force on the connecting rod from top to bottom, the force is evenly distributed to both sides of the U-shaped rib through the two pressure plates hinged with the connecting rod. The "balance" here does not mean equal, but even if there is a slight deviation between the two limbs of the U-shaped rib, the assembly and positioning device can automatically adjust the force applied to the two limbs of the U-shaped rib, so that the two limbs of the U-shaped rib and the bridge deck The gap siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com