Color master batch supply device and production equipment

A technology for supplying device and color masterbatch, applied in the field of plastic product production, can solve the problems of difficult color change, reduce production efficiency, etc., and achieve the effects of improving work efficiency, reducing the frequency of adding color masterbatch, and avoiding the phenomenon of supply interruption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The color masterbatch supply device provided in this embodiment is used in production equipment.

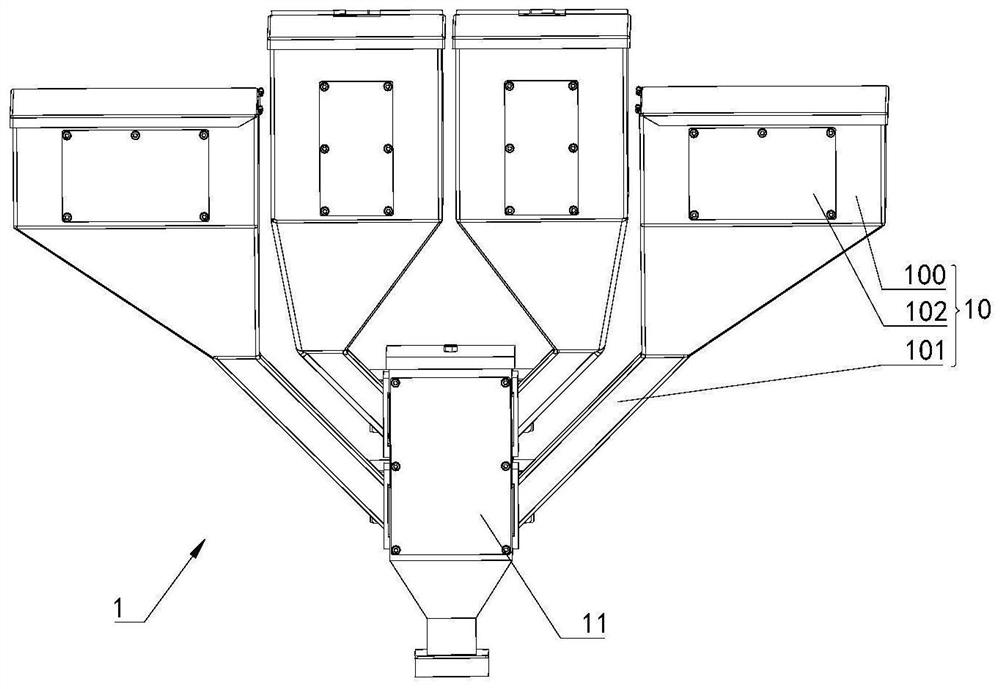

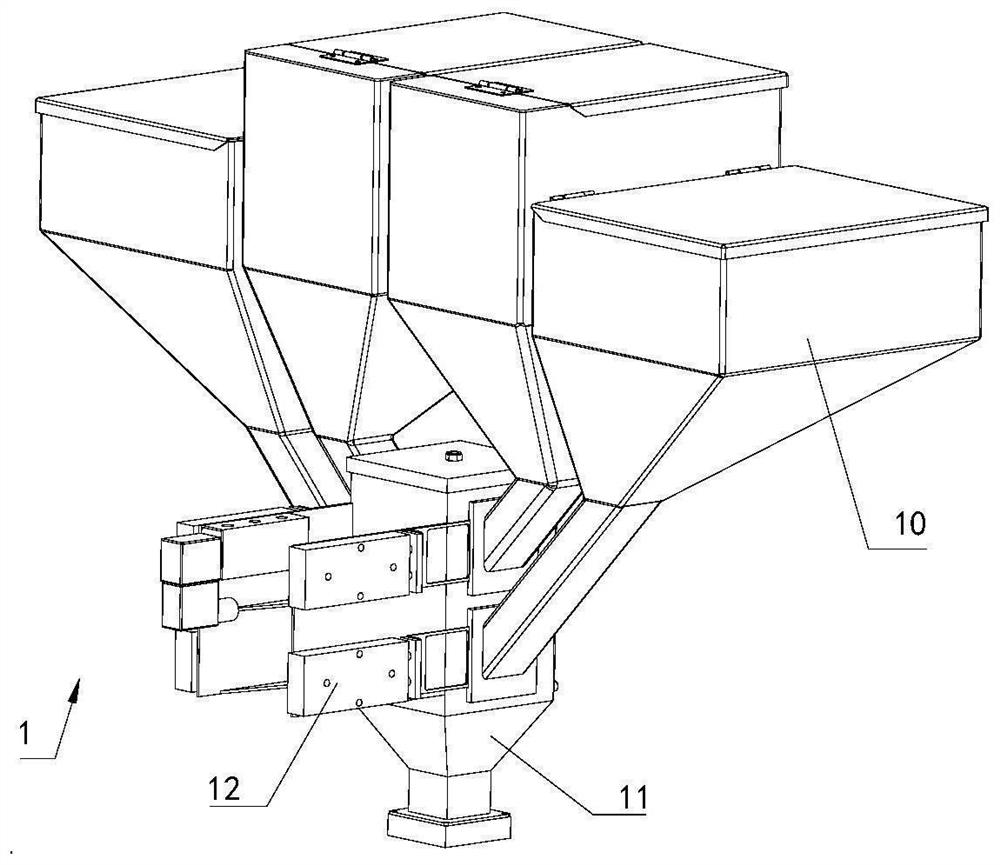

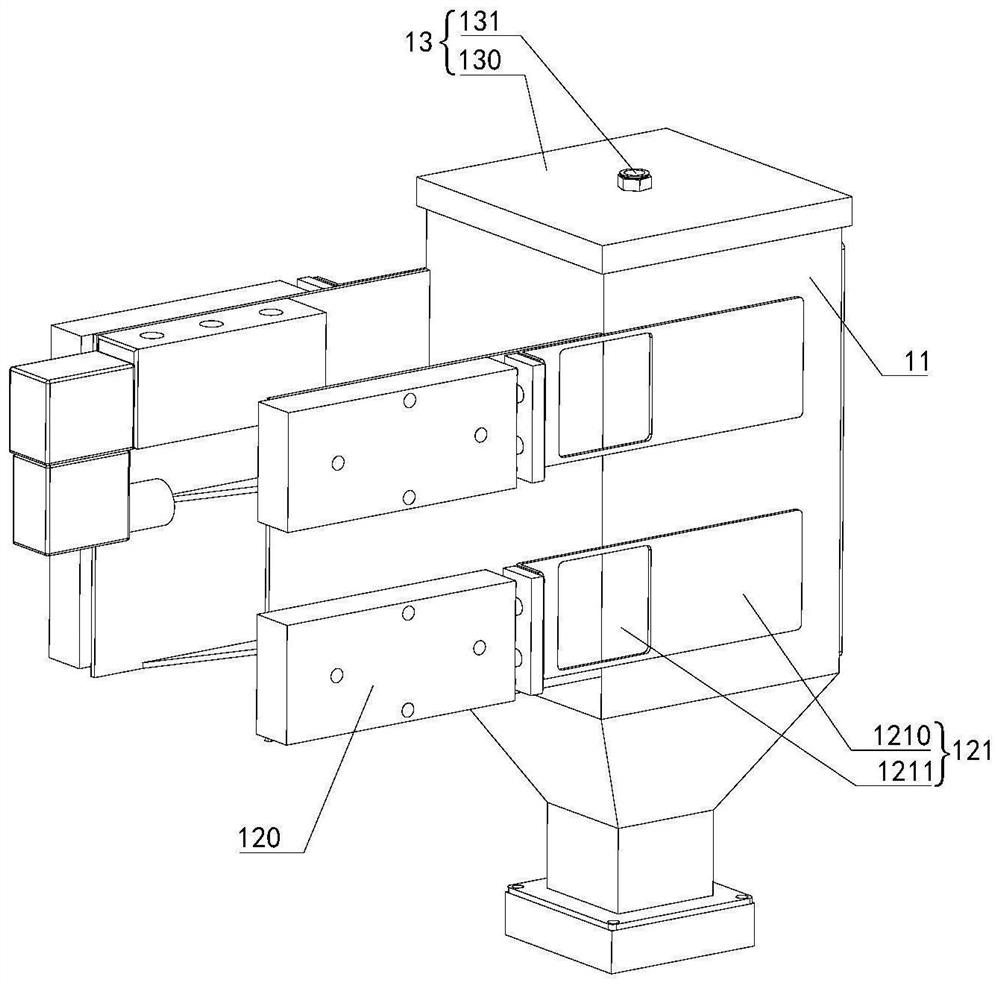

[0041] see Figure 1 to Figure 4 and combine Figure 5 and Figure 6 As shown, the color masterbatch supply device 1 provided in this embodiment includes a mixing box 11 , a storage box 10 and a switch mechanism 12 .

[0042] Hereinafter, the above-mentioned components of the color masterbatch supply device 1 will be specifically described.

[0043] In this embodiment, the storage box 10 is used to store the color masterbatch. There are multiple storage boxes 10, and at least one storage box 10 in the multiple storage boxes 10 stores one color. For example, when the quantity of the storage bins 10 is four, then the four storage bins 10 can respectively store a kind of color masterbatch, or, every two storage bins 10 in the four storage bins 10 store a kind of color masterbatch. Masterbatch, perhaps, four storage boxes 10 all store a kind of color masterbatch, perhaps, ...

Embodiment 2

[0072] Embodiment 2 provides a kind of production equipment, and this embodiment includes the color masterbatch supply device in embodiment 1, and the technical feature of the color masterbatch supply device disclosed in embodiment 1 is also applicable to this embodiment, and embodiment 1 has been The technical characteristics of the disclosed extruder will not be described repeatedly.

[0073] to combine Figure 1 to Figure 4 and see Figure 5 and Figure 6 As shown, the production equipment 21 provided in this embodiment includes a main material box 20 , a color masterbatch supply device 1 and an extruder 2 .

[0074] Hereinafter, the above-mentioned components of the production facility 21 are described.

[0075] The color masterbatch supply device 1 is arranged on the side of the main material box 20 , and the outlet 111 of the main material box 20 and the outlet 111 of the mixing box 11 are both communicated with the inlet 110 of the extruder 2 .

[0076] The main mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com