Active plugging device of connector

A plug-in device and connector plug technology, which is applied in the field of connector active plug-in devices, can solve the problems of affecting the closing and opening functions of the box, reducing the overall reliability, and large application limitations, so as to ensure straightness and ensure Mating quality, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

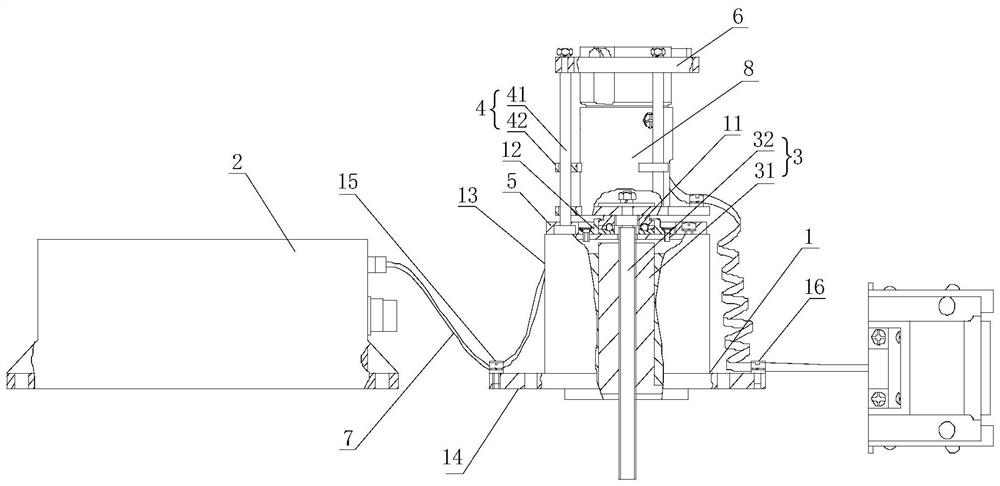

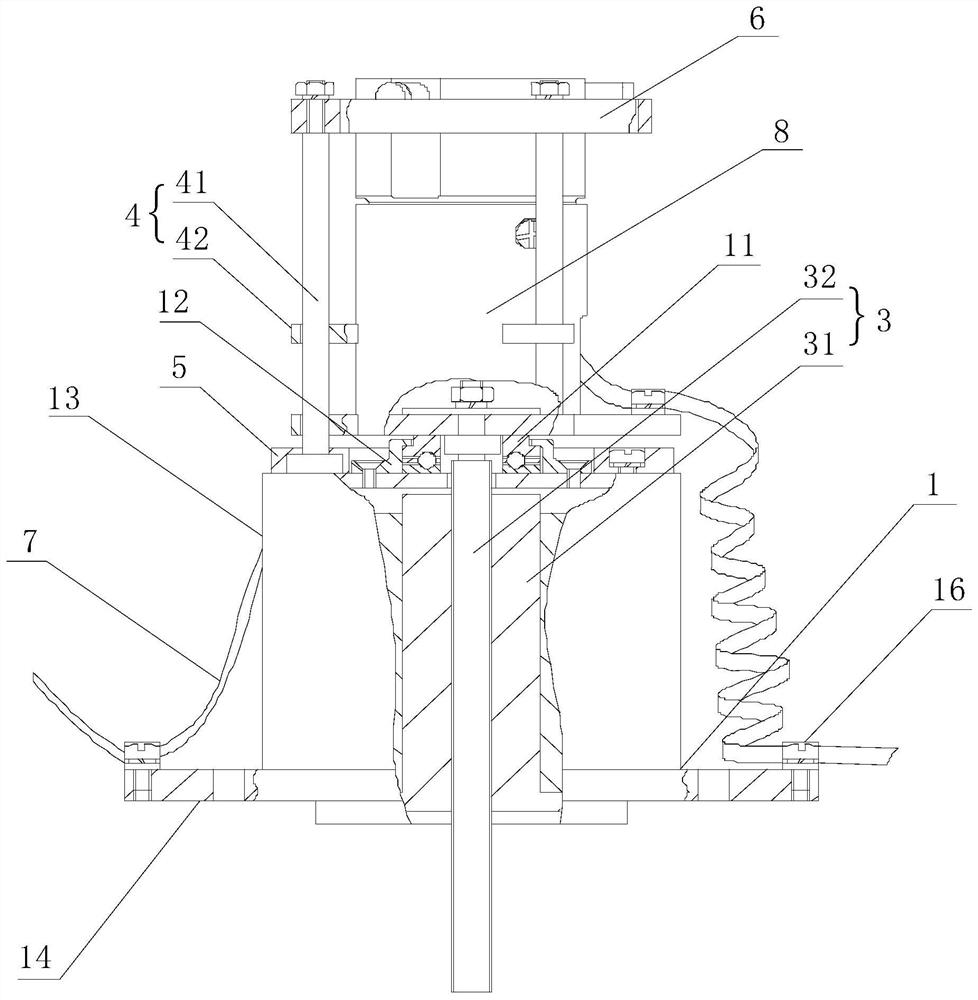

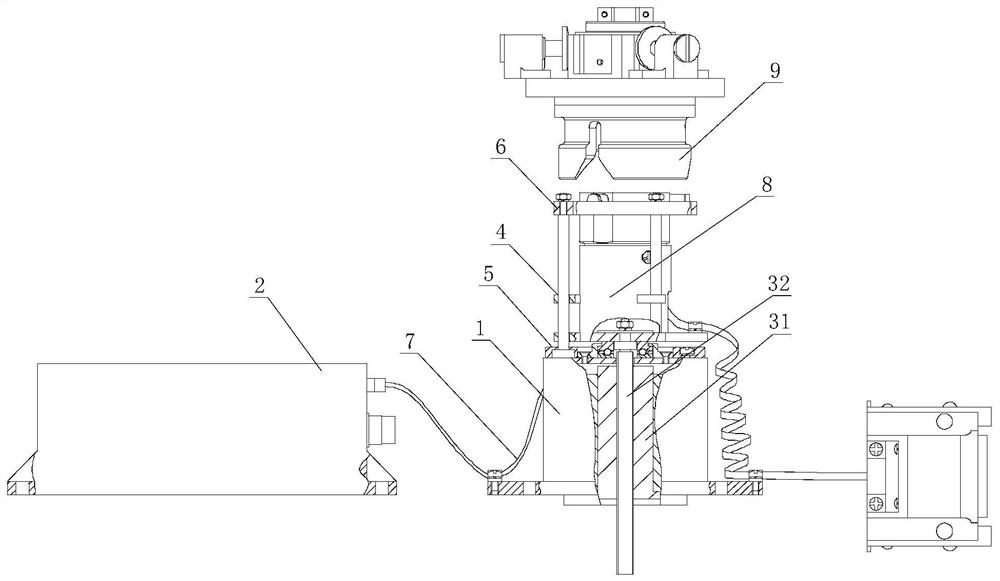

[0025]Such asfigure 1 ,figure 2 ,image 3 withFigure 4As shown, a connector active plug device is applied to the connector plug, including a DC motor 1 and a controller 2 connected to the DC motor 1, and the DC motor 1 is provided with a wire connected to the connector plug 8. Bar drive assembly 3, the DC motor 1 and the connector plug is also provided with a guide assembly 4, and the DC motor 1 also has a Hall sensor for calculating a DC motor 1 motion stroke, the Hall sensor and control. The device 2 is connected.

[0026]By providing the screw transmission assembly 3 connected to the connector plug 8 on the DC motor 1, the rotation of the DC motor 1 converts the rotation of the DC motor 1 into the straight line movement of the lead screw 32, since the connector plug is disposed on the lead bump transmission On the assembly 3, therefore, it is only necessary to control the direction of motion of the lead screw 32 sensing assembly by controlling the direction of rotation of the DC moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com