A reclaiming mechanism and detection equipment for sheet-type thin material products

A technology for taking out materials and products, which is applied in the direction of thin material processing, lighting and heating equipment, conveyors, etc. materials and products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

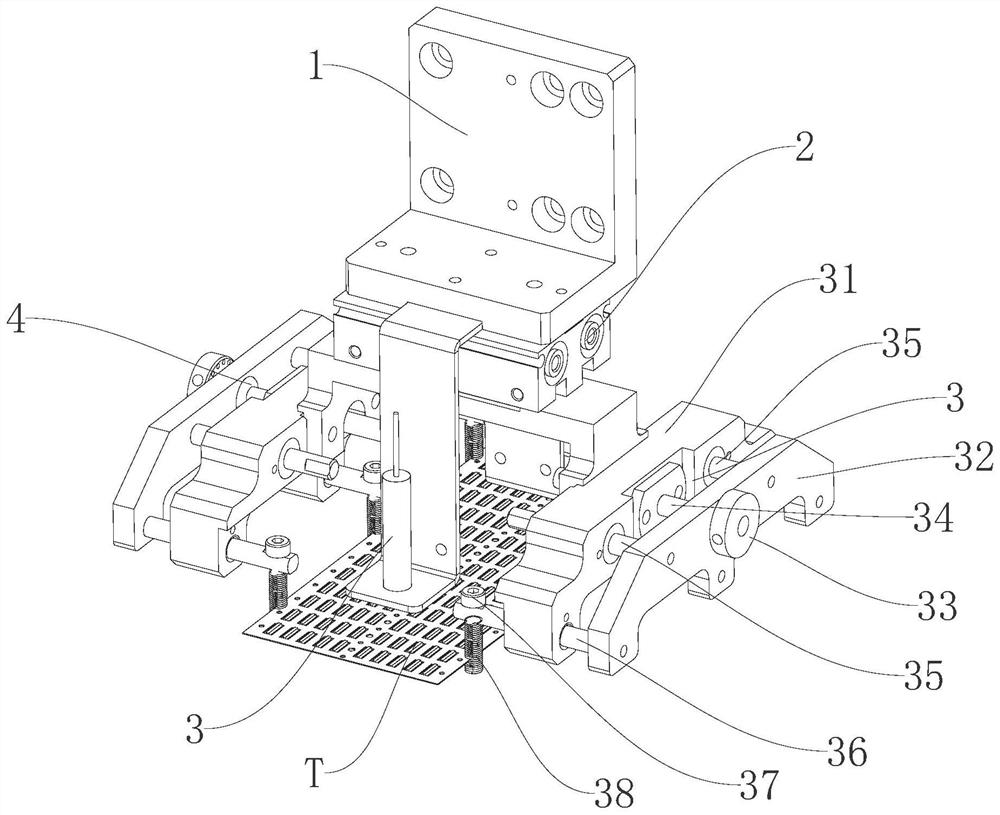

[0021] Example: such as figure 1 As shown, a material retrieving mechanism includes a mounting frame 1, a sliding table cylinder 2, a sensor 3 and two flexible clamping components. The sliding table cylinder 2 is fixed on the mounting frame 1, and the sliding table cylinder 2 consists of two left and right set The slider and the main body of the slide cylinder installed on the two slides, the slider on the left side of the main body of the slide cylinder is called the left slider, and the slider on the right side of the main body of the slide cylinder is called the right slider , the two flexible clamping components are respectively called the first flexible clamping component 3 and the second flexible clamping component 4, the first flexible clamping component 3 is located on the right side of the right slider, and the second flexible clamping component 4 is located The left side of the left slider; the first flexible clamping assembly 3 includes an adjustment fixed plate 31,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com