Biochemical reaction tank sludge transfer system and sludge transfer method

A biochemical reaction and reaction tank technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as damage to aeration pipes, low transfer efficiency, and damage to aerators. , to increase safety, reduce transport costs, and improve transport efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

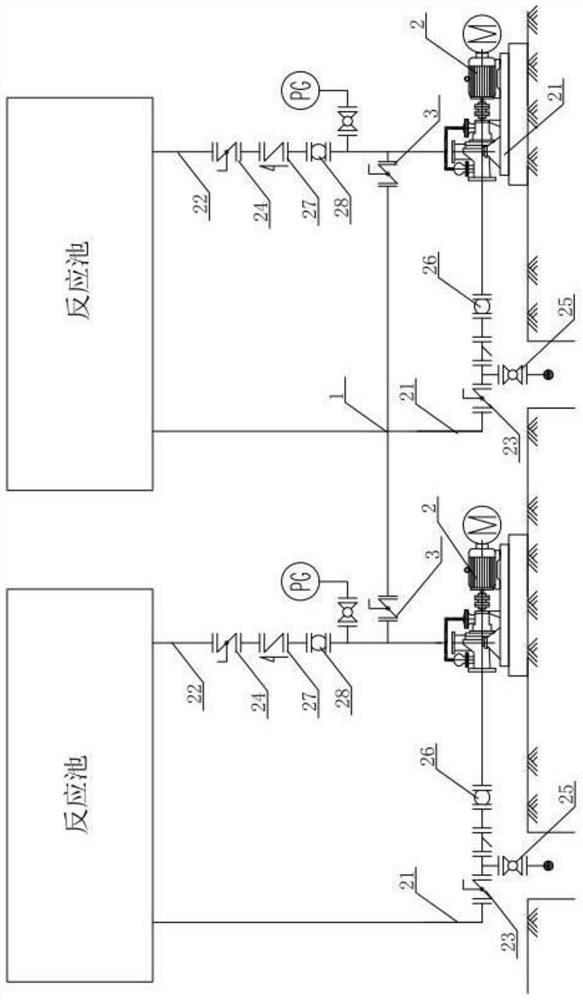

[0025]A biochemical reactive pool sludge transportation system, including at least two or more reaction tanks, and the outer side of each reaction cell is provided with a sewage circulation pump 2, the sewage circulation pump 2 is connected to the circular pump inlet line 21 and the circulating pump outlet pipe line 22, cycle A circulating pump inlet valve 23 is provided on the pump inlet line 21, and a circulating pump outlet valve 24 is provided on the circulating pump outlet line 22; a sludge transfer line 1 is connected between the circulating pump outlet pipe lines 22 of each reaction cell. The sludge transport line 1 achieves sludge transport between the reaction tanks between each other; the sludge transport valve 3 is provided at both ends of the sludge transfer line 1 and the position of the circular outlet pipeline 22 connected thereto. When the reactive pool sludge transport valve 3 is closed, two reaction tanks work independently. When these two sludge turn valves are tu...

Embodiment 2

[0033]A biochemical reaction pool sludge transfer method, including the following steps,

[0034](1) After one of the biochemical reactive pool sludge precipitation, first eliminate the upper cleaner by decanter, open its corresponding sludge transfer valve and sludge transport line, the other end of the sludge needs to transport the sludge transfer in the end of the reaction pool end. Mud turnover;

[0035](2) Close the circulation pump outlet valve of the reaction cell to be transferred to the sludge, keep the sewage circulation pump continuously, and the sludge in the reaction pool is transferred to the corresponding reaction cells of the sludge transport line communication.

[0036](3) The end of the transfer, the reaction tank to be transported to the sludge is evacuated.

[0037]Similarly, the sludge in other reaction cells can also be transported into the reaction tank connected thereto.

[0038]Under normal operation, close the sludge transport valve 3 between the reaction pool, each react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com