Rapid scanning method and system for detecting microcracks on surface of pressure equipment

A technology for detecting pressure and scanning method, applied in measurement devices, instruments, material analysis by electromagnetic means, etc., can solve problems such as safety accidents, missed inspections and improper disposal, and achieve the effect of overcoming engineering technical defects and shortening scanning distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]In order to make the objects, technical solutions, and advantages of the present invention more clearly, the present invention will be described in further detail below by way of illustration and examples. It should be understood, however,, however, as used herein is intended to explain the invention, and is not intended to limit the scope of the invention.

[0028]Unless otherwise defined, all technical terms and scientific terms used herein are generally understood by those skilled in the art of the present invention, and the terms used in the specification of the present invention are intended to describe specific implementation purposes only. The purpose of the example is not intended to limit the invention.

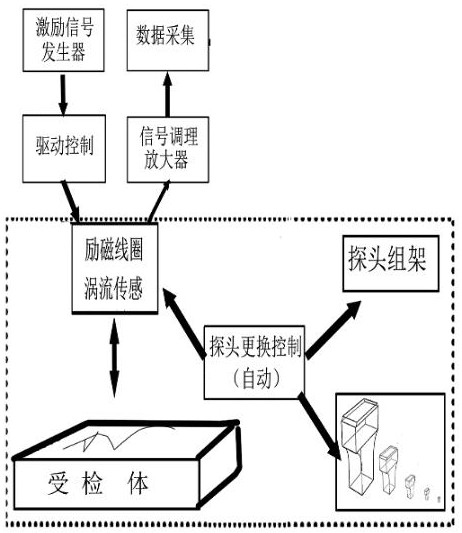

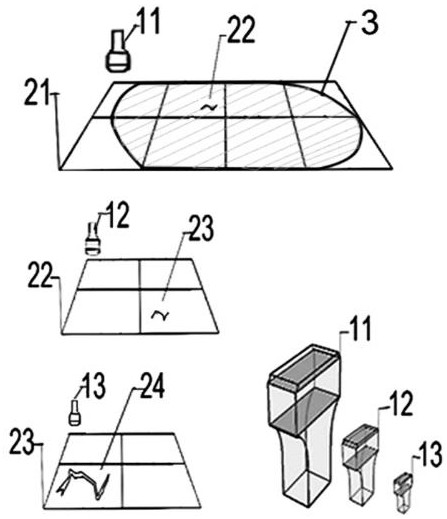

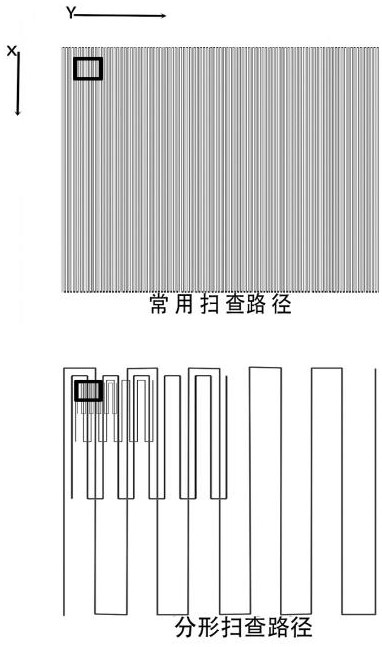

[0029]Such asfigure 1 As shown, a system for detecting a surface microcrack of a pressure device comprising a subject; a substantial vehicle having a exciting coil vortex sensing device; the excitation magnetic coil vortex sensing device is driven by an excitation signal g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com