Learning device, inspection device, learning method, and inspection method

A technology for learning devices and inspection devices, which is applied in measuring devices, machine learning, scientific instruments, etc., can solve the problem of a large number of images, achieve high-precision substrate inspection, and reduce capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

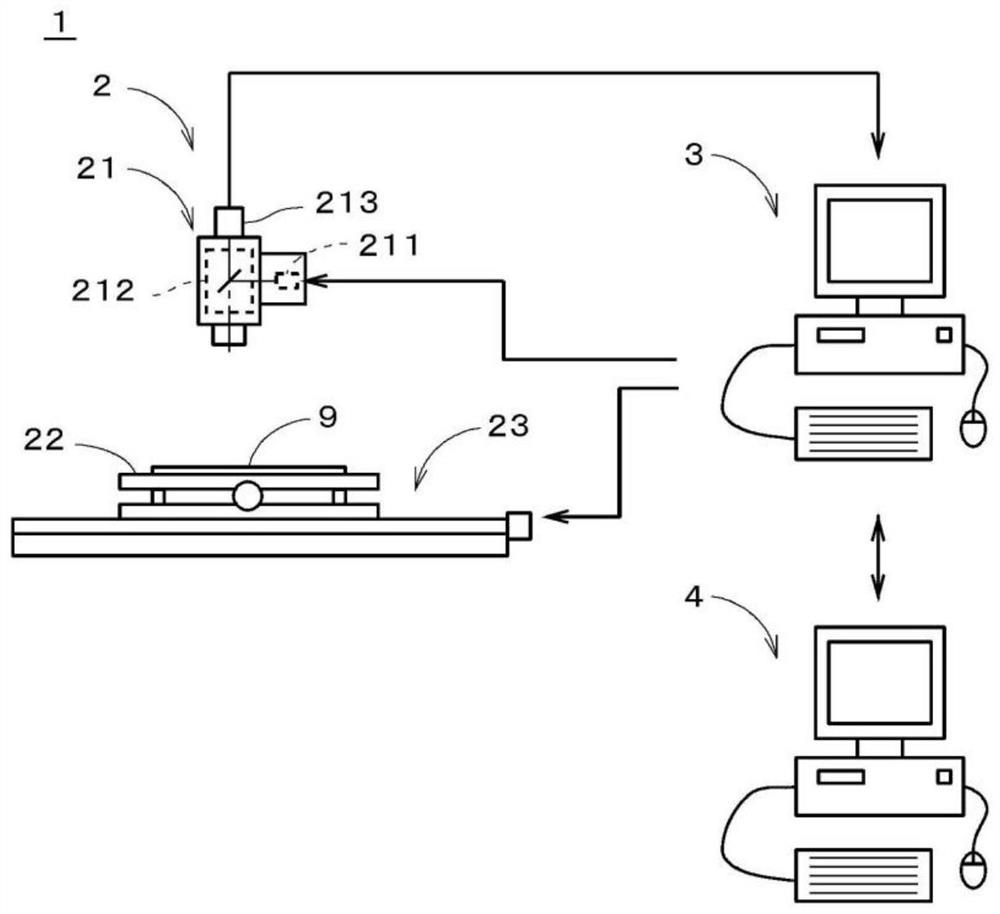

[0043] figure 1 It is a figure which shows the structure of the inspection apparatus 1 which concerns on one Embodiment of this invention. The inspection device 1 is, for example, a device that inspects the appearance of a printed wiring board 9 (hereinafter also simply referred to as "board 9") before mounting electronic components. A pattern (for example, a wiring pattern or an electrode pattern formed of copper) is formed on the surface of the substrate 9 . On the substrate 9 , for example, there are regions where copper plating is exposed, regions where copper wiring is covered with solder resist as a protective film, and regions where solder resist is directly disposed on the surface of the base material.

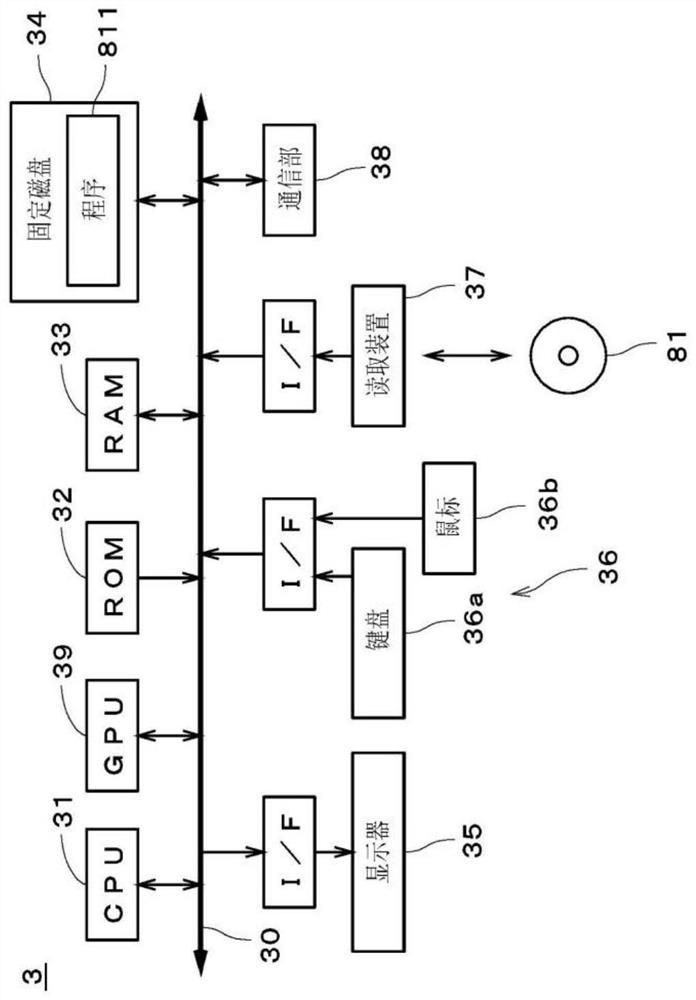

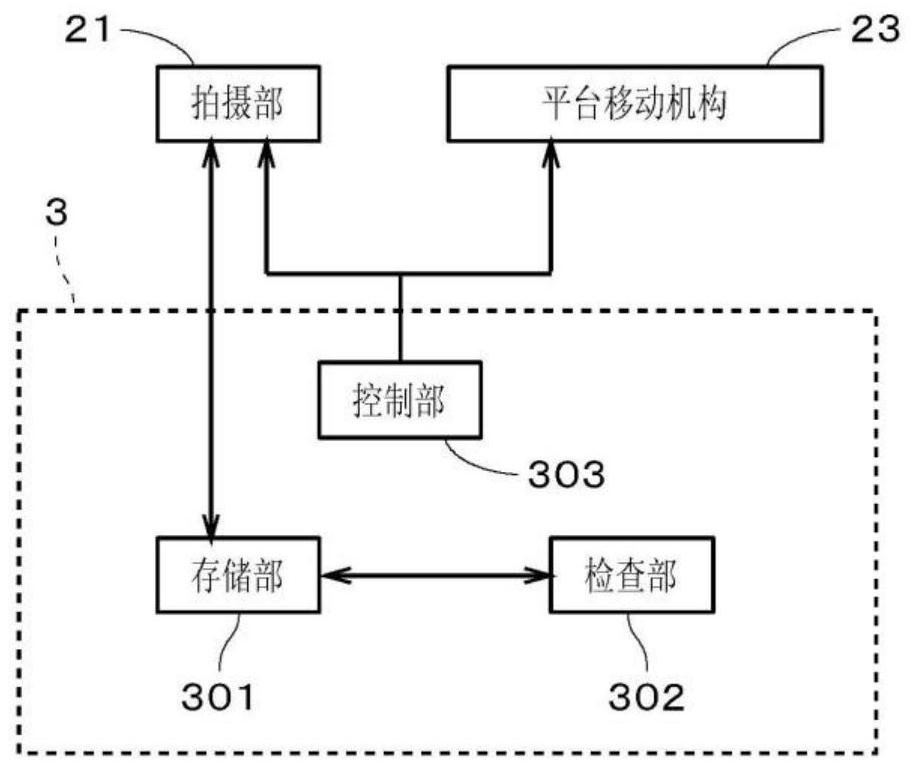

[0044] The inspection apparatus 1 includes: an apparatus body 2 for photographing a substrate 9 , a first computer 3 , and a second computer 4 . The first computer 3 and the second computer 4 are respectively processing devices including a computing unit. The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com