Transformer valve sleeve insulation support and installation guide structure assembly and assembly method

A technology of insulating support and guiding structure, applied in the direction of transformer/inductor coil/winding/connection, inductance/transformer/magnet manufacturing, electrical components, etc., it can solve the problem that it is not easy to form a reliable support structure and the installation structure of the valve casing is stable Poor performance, inconvenient orientation of the valve casing, etc., to reduce the mechanical stress of the box wall, reduce the risk of oil leakage, and have good practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are part of the embodiments of the present invention, not all of them.

[0027] A transformer valve bushing insulation support and installation guide structure assembly, comprising: a valve bushing insulation support structure, and a valve bushing installation guide structure.

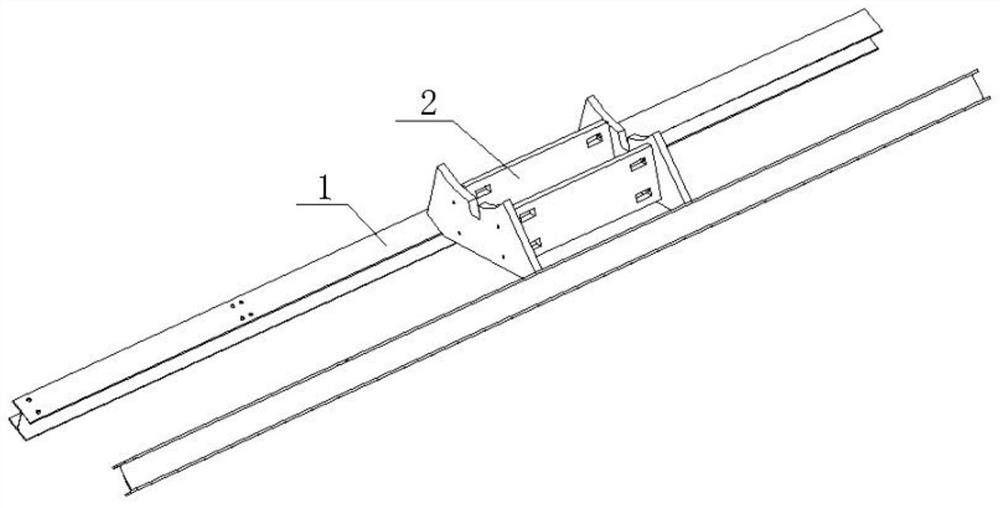

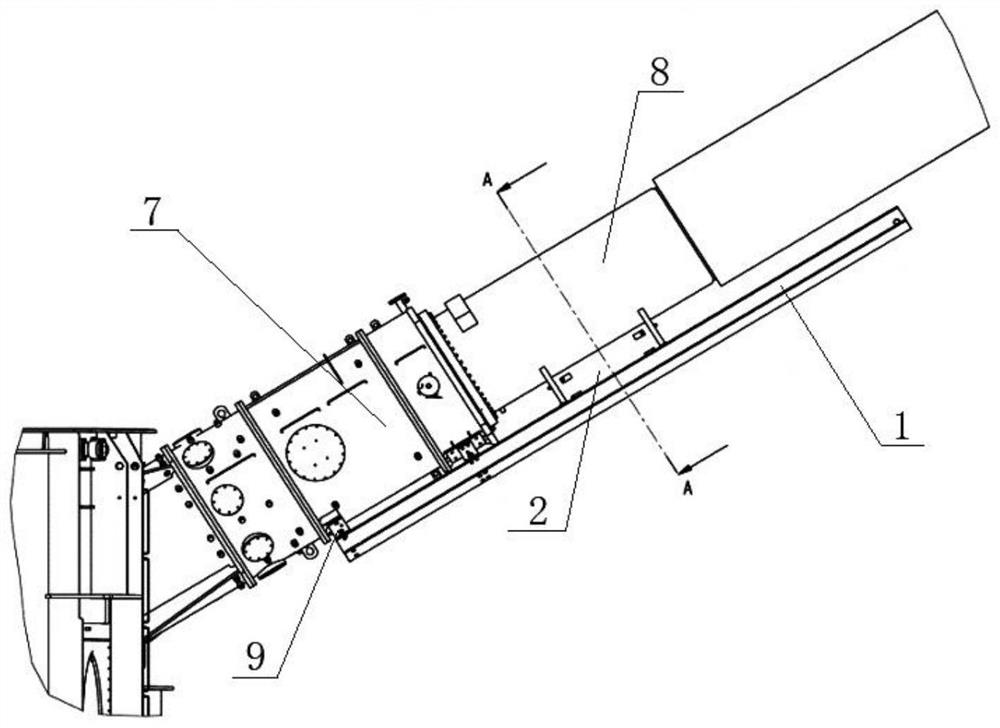

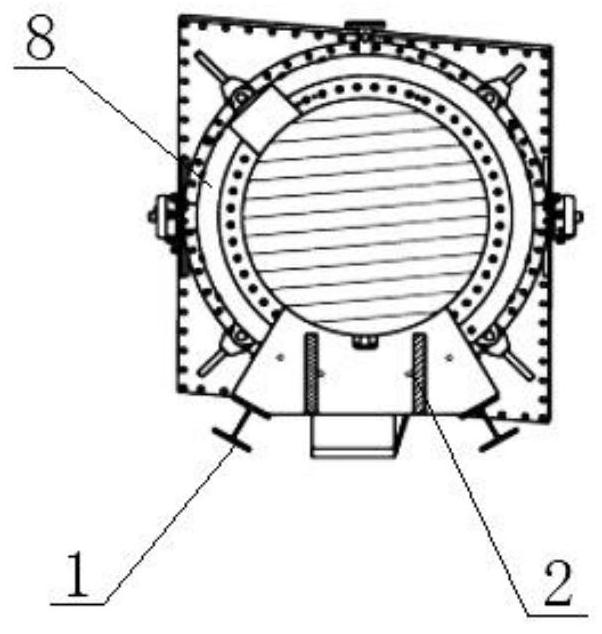

[0028] Such as figure 1 As shown, it is a schematic diagram of the installation guide structure of the embodiment of the present invention; as figure 2 As shown, it is a schematic diagram of the use state of the installation guide structure of the embodiment of the present invention; as image 3 As shown, it is a cross-sectional view of the installation guide structure of the embodiment of the present invention along the direction A. The valve sleeve 8 is fixedly installed on the valve lifting seat 7, and two detac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com