Automatic chestnut opening equipment

A kind of equipment and technology of chestnut, applied in the field of automatic chestnut opening equipment, can solve the problems of difficult positioning, low efficiency of manual methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] An automation for chestnut opening equipment such as figure 1 As shown, it includes a bottom plate 1, a first support frame 2, a servo motor 3, a rotating mechanism 4, a feeding mechanism 5, a pressing mechanism 6 and a material receiving mechanism 7. The top right side of the bottom plate 1 is provided with a first support frame 2, The top of the first support frame 2 is provided with a servo motor 3, the middle part of the top of the bottom plate 1 is provided with a rotating mechanism 4, the rear side of the top of the bottom plate 1 is provided with a blanking mechanism 5, and the middle part of the top of the bottom plate 1 and the rotating mechanism 4 are connected with a pressing mechanism 6 , The lower part of the rotating mechanism 4 is provided with a receiving mechanism 7.

[0027] The staff places the chestnuts in the feeding mechanism 5, and then starts the servo motor 3 to work, the servo motor 3 drives the rotating mechanism 4 to work, the rotating mechan...

Embodiment 2

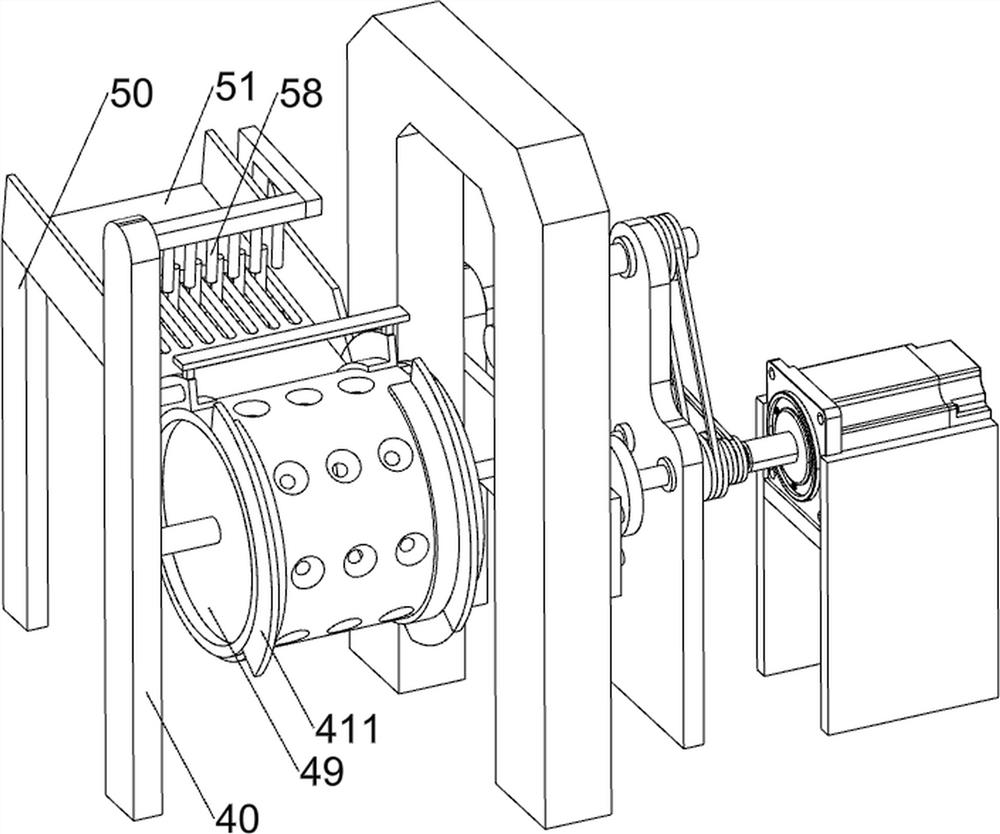

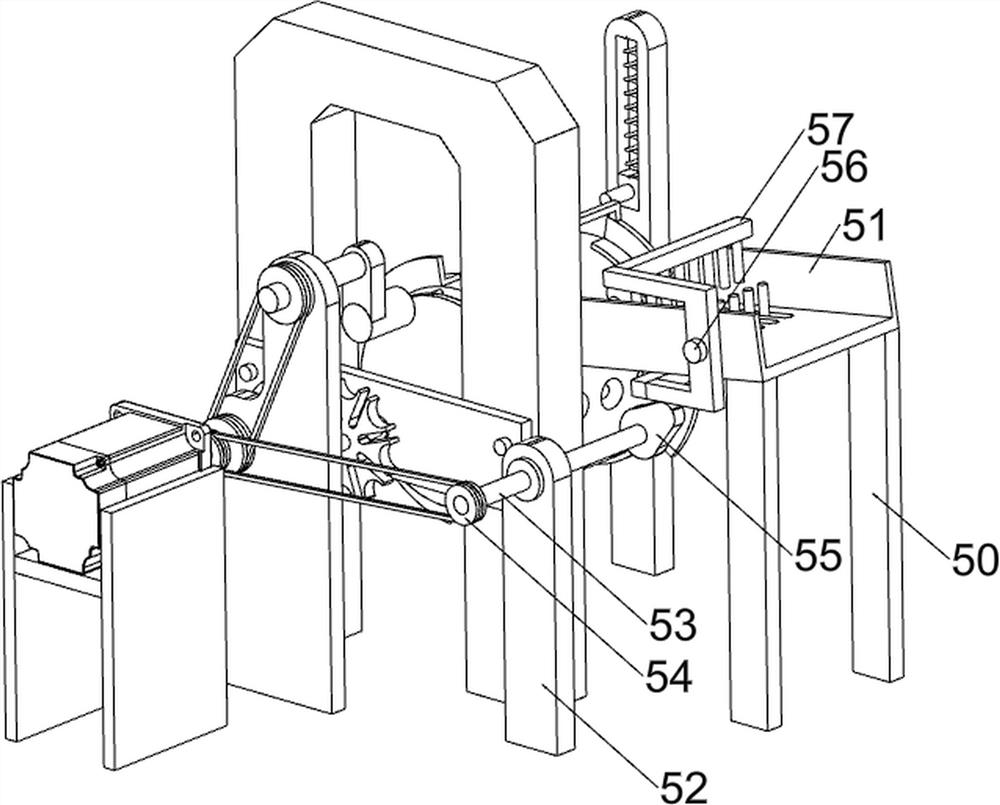

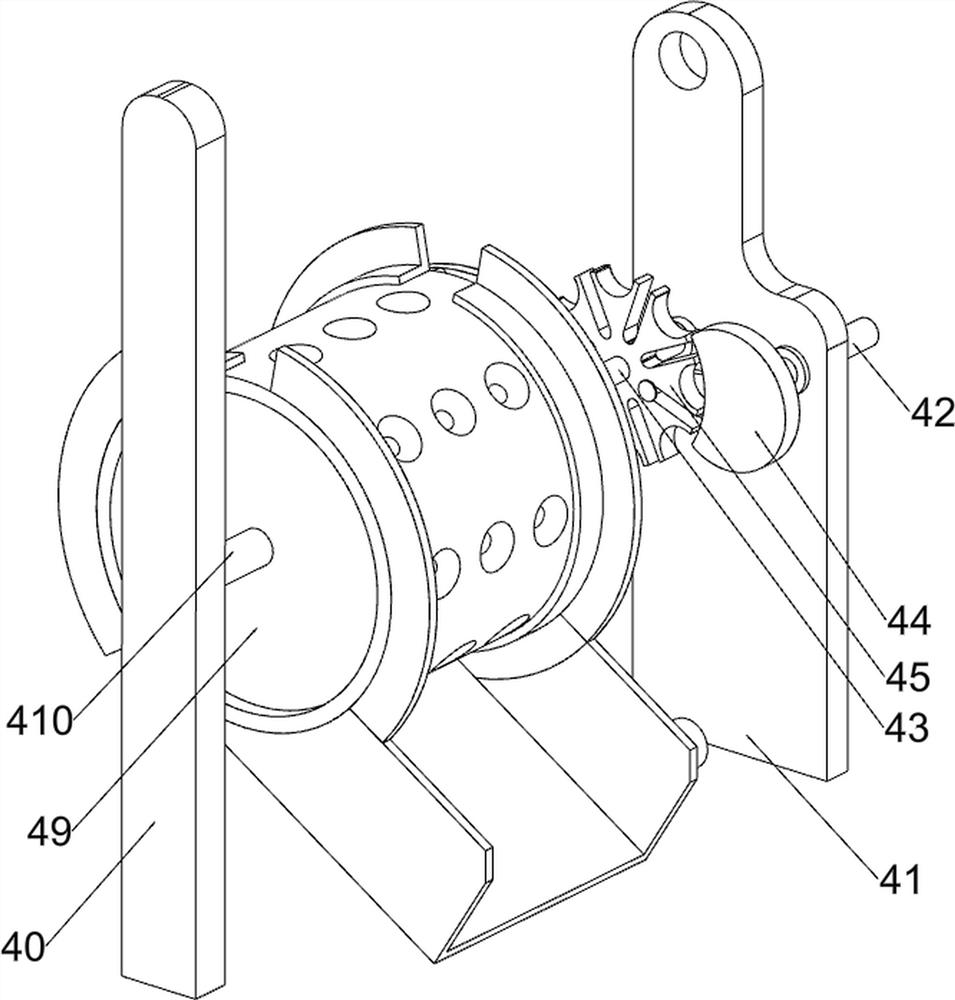

[0029] On the basis of Example 1, such as Figure 2-7 As shown, the rotating mechanism 4 includes a first supporting plate 40, a second supporting plate 41, a first rotating shaft 42, a second rotating shaft 43, a convex circle 44, a special-shaped rotating disk 45, a first connecting disc 46, and a first fixing rod 47. , rotating bucket 48, the second connecting disc 49, the first connecting rod 410 and the protective plate 411, the left side of the bottom plate 1 top is provided with the first support plate 40, the right side of the bottom plate 1 top is provided with the second support plate 41, the servo motor 3 The output end is connected with a first rotating shaft 42, the first rotating shaft 42 is rotationally connected with the second supporting plate 41, the middle part of the second supporting plate 41 is rotationally connected with a second rotating shaft 43, and the first rotating shaft 42 is connected with a convex circle 44, The second rotating shaft 43 is conne...

Embodiment 3

[0038] On the basis of Example 2, such as figure 1 and Image 6 As shown, a limit frame 8 is also included, and the limit frame 8 is symmetrically connected between the protective plates 411 .

[0039] Limiting frame 8 is used to limit the position that opening blade 610 moves downwards, makes opening blade 610 carry out accurate opening to chestnut in the groove of rotating bucket 48.

[0040] It also includes a placement frame 9, a storage basket 10, a handle 11 and a filter screen 12. The front side of the top of the bottom plate 1 is connected to the placement frame 9, and the interior of the placement frame 9 is slidingly connected to the storage basket 10. The sliding type inside the storage basket 10 is provided with a filter. The net 12 is connected with a handle 11 on the front side of the storage basket 10 .

[0041] The staff can place the storage basket 10 in the placement frame 9 to fix the storage basket 10, and the chestnuts that have been opened will drop ont...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap