A grinding and screening integrated device for recycling foundry waste sand

A technology for foundry waste sand and screening, applied in grain processing and other directions, can solve the problems of insufficiency, increased worker workload, poor grinding effect of waste sand, etc., so as to reduce workload, improve grinding efficiency and effect, and improve grinding The effect of efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

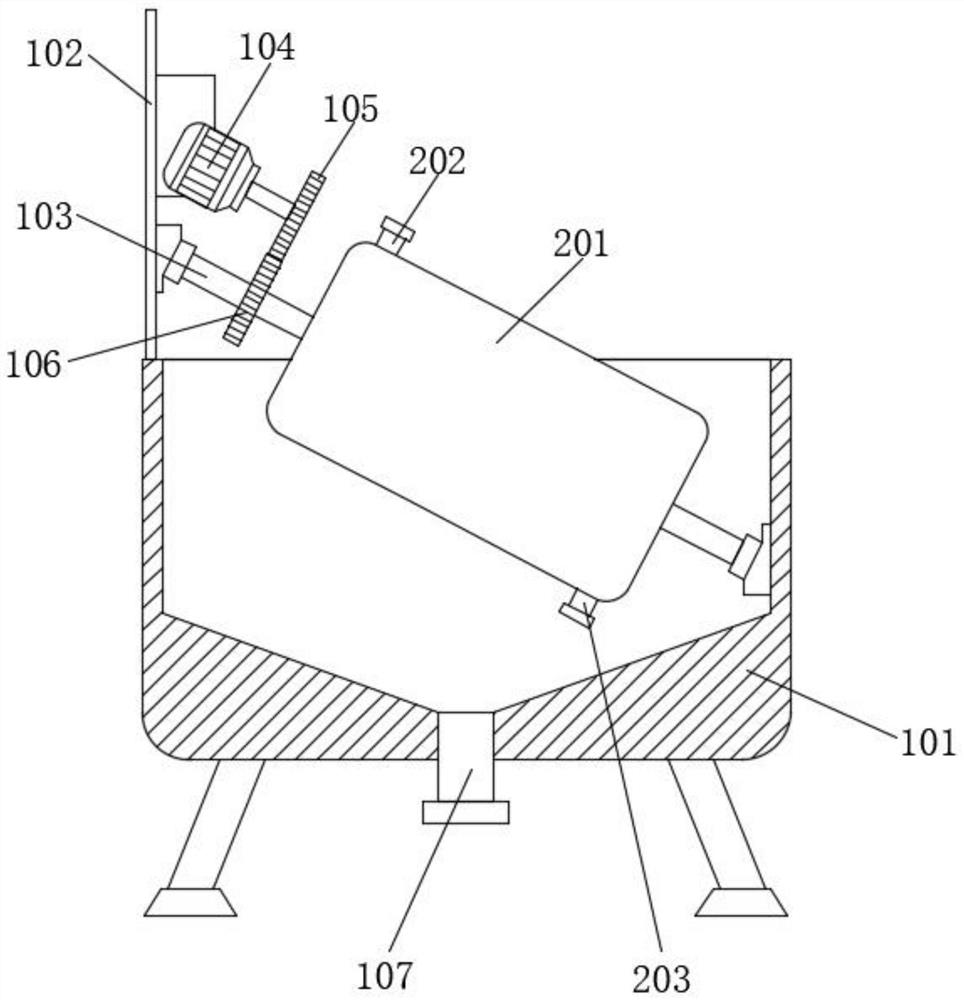

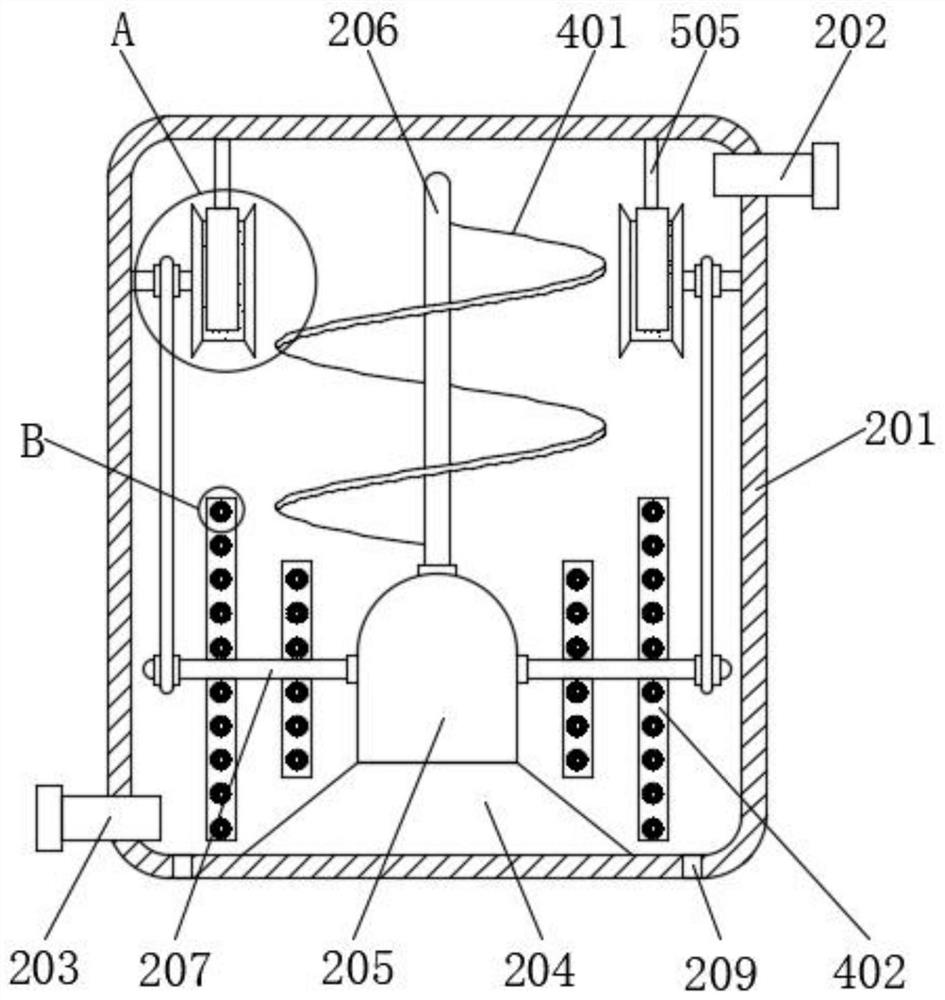

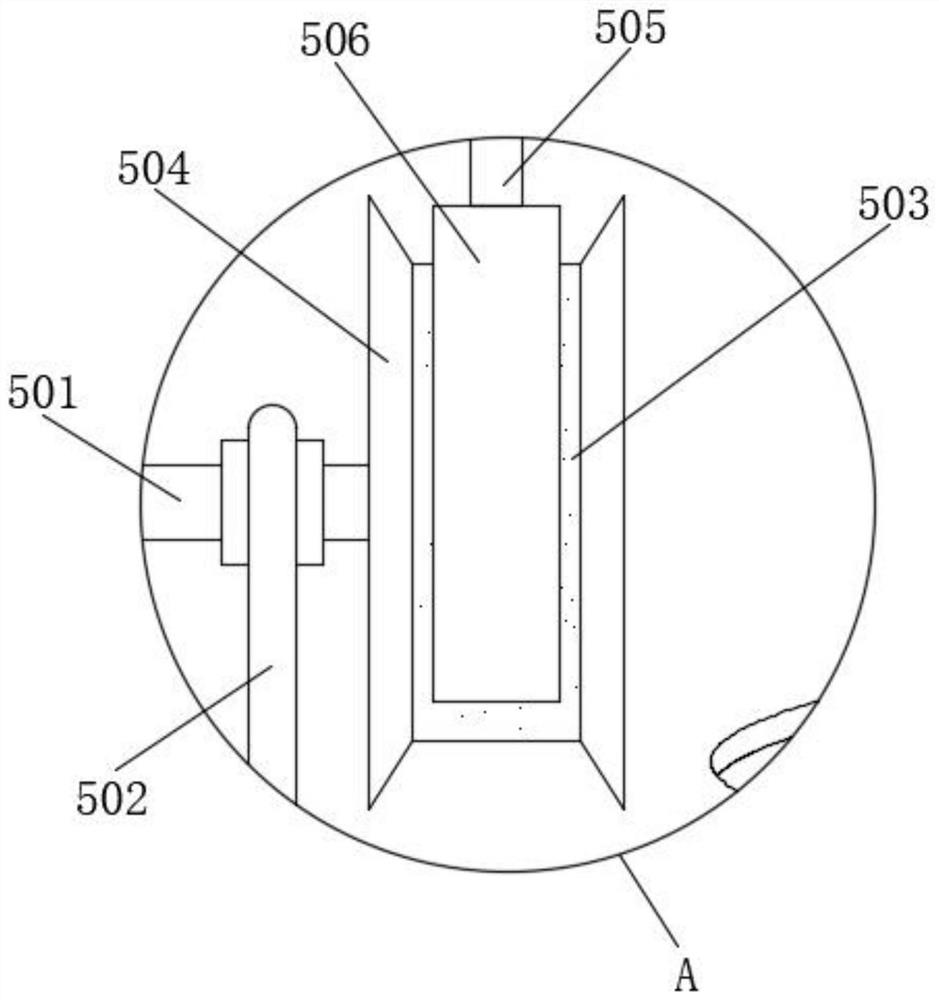

[0042] see Figure 1-2 and Figure 6 , an integrated grinding and screening device for recycling foundry waste sand, including a recovery box 101, a turning and grinding cylinder 201 is arranged in the recovery box 101, a supporting vertical plate 102 is fixedly connected to the top of the recovery box 101, and a turning and grinding cylinder 201 is fixed. The middle part of both ends is all fixedly connected with connecting rotating shaft 103, and two connecting rotating shafts 103 are respectively connected with the inner wall of supporting vertical board 102 and recovery box 101 and rotatingly connected, and one side of supporting vertical board 102 is fixedly connected with first motor 104, and the first motor 104 A driving gear 105 is fixedly connected to the output end of the shaft, and a driven gear 106 matching the driving gear 105 is fixedly sleeved on the outer wall of one of the connecting shafts 103. A plurality of screening holes 209 are provided on the outer wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com