Automobile part paint spraying device

A technology of auto parts and water spraying devices, applied in the field of painting, can solve the problems of increasing the value of repeated use of paint, uneven spraying, separation of paint that cannot be attached, etc., and achieve the effect of increasing the value of repeated use and preventing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

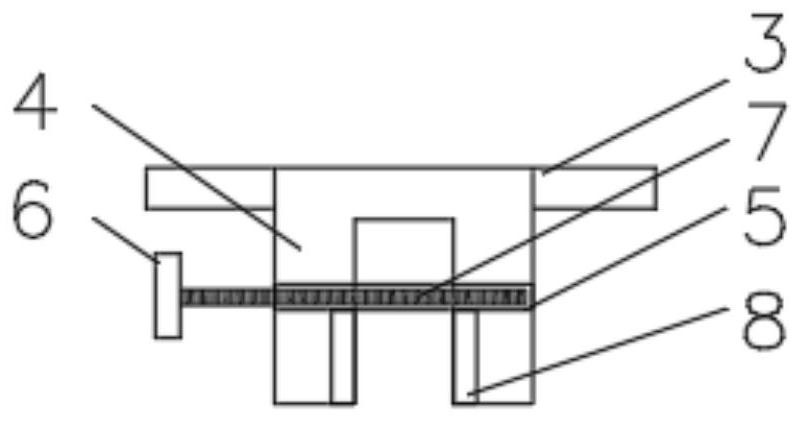

[0034] see Figure 1-4 , the present invention provides a technical solution: a paint spraying device for automobile parts, comprising an outer frame 1, one side of the outer frame 1 is connected with a storage tank 2, the inner wall of the outer frame 1 is equipped with a fixed rod 3, and one part of the fixed rod 3 A clamping plate 4 is installed on the side, and one side of the clamping plate 4 is provided with a mounting hole 5, the inner wall of the mounting hole 5 is provided with threads, one side of the clamping plate 4 is connected with a nut 6, and one side of the nut 6 is equipped with a threaded rod 7, and the screw thread One end of the rod 7 runs through the splint 4 and is connected to the mounting hole 5. The side of the splint 4 away from the nut 6 is fixedly connected with a rubber plate 8, and the inner wall of the outer frame 1 is installed with a fixed plate 9 near the position of the storage barrel 2. The fixed plate 9 One side near the outer frame 1 is p...

Embodiment 2

[0043] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1,

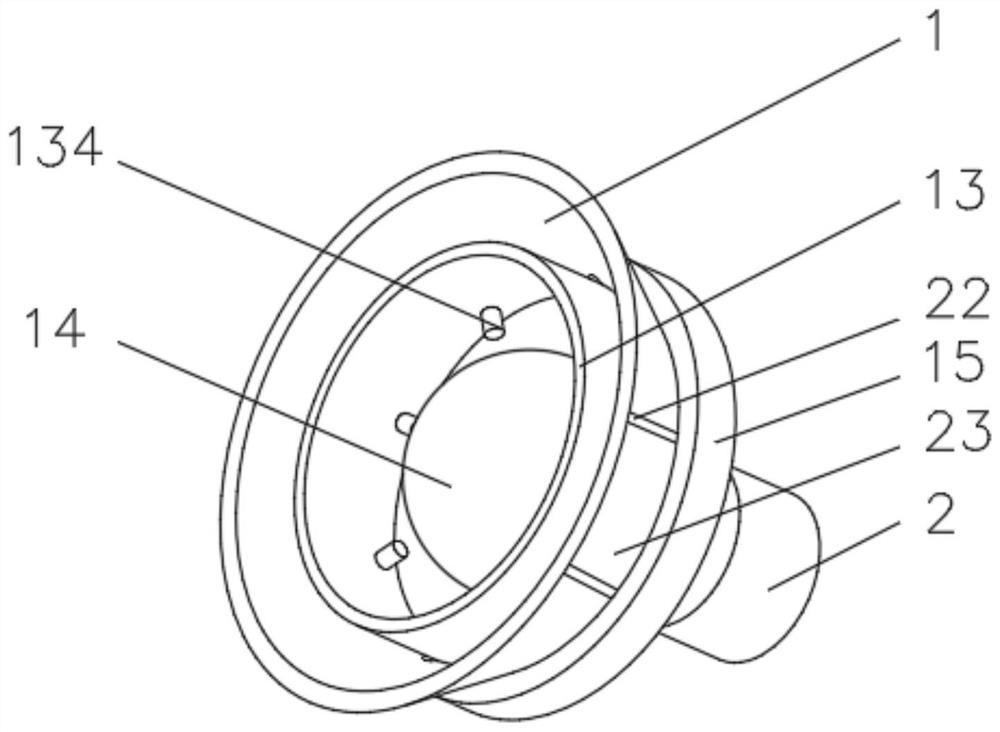

[0044] The inner wall of the outer frame 1 is equipped with a water spray device 13, the water spray device 13 includes a water tank 131, one side of the water tank 131 is fixedly connected with the outer frame 1, and the side of the water tank 131 away from the outer frame 1 is connected with a water pipe 132, and one side of the water pipe 132 A water pump 133 is installed on the side, and the end of the water pipe 132 away from the water tank 131 is communicated with a water outlet 134 .

[0045] When in use, the water pump 133 is turned on to transport the water inside the water tank 131 from the water pipe 132 to the water outlet 134. The installation of the water spray device increases the fluidity of the splashed paint and prevents the splashed paint from solidifying rapidly Stick to the inner wall.

Embodiment 3

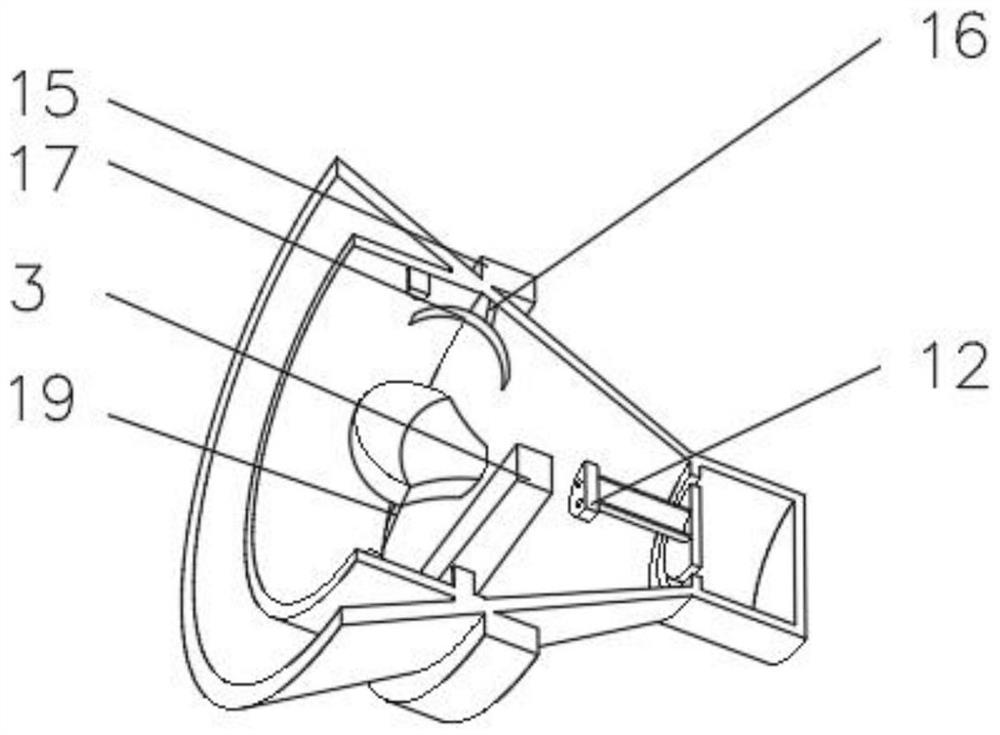

[0047] see Figure 1-6 , the present invention provides a technical solution: on the basis of Embodiment 2, a connecting rod 19 is installed on the inner wall of the outer frame 1 close to the water spray device 13, and a limit ball 14 is installed on one end of the connecting rod 19, and the limit ball 14 One side is equipped with knocking device 18.

[0048] A concave-convex plate 20 is installed near the position of the limit ball 14 to the fixed rod 3, and the concave-convex plate 20 is arc-shaped.

[0049] The percussion device 18 includes an elastic rod 181, one end of the elastic rod 181 is fixedly connected with a percussion ball 182, and one end of the elastic rod 181 away from the percussion ball 182 is fixedly connected with a movable block 183, and one end of the movable block 183 is fixedly connected with a spring 184, One end of the spring 184 away from the movable block 183 is fixedly connected with the limit ball 14 .

[0050] During use, the spray head 12 sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com