High-salinity wastewater freezing, concentrating and separating treatment device

A high-salt wastewater, freeze-concentration technology, applied in frozen water/sewage treatment, water/sludge/sewage treatment, grain treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

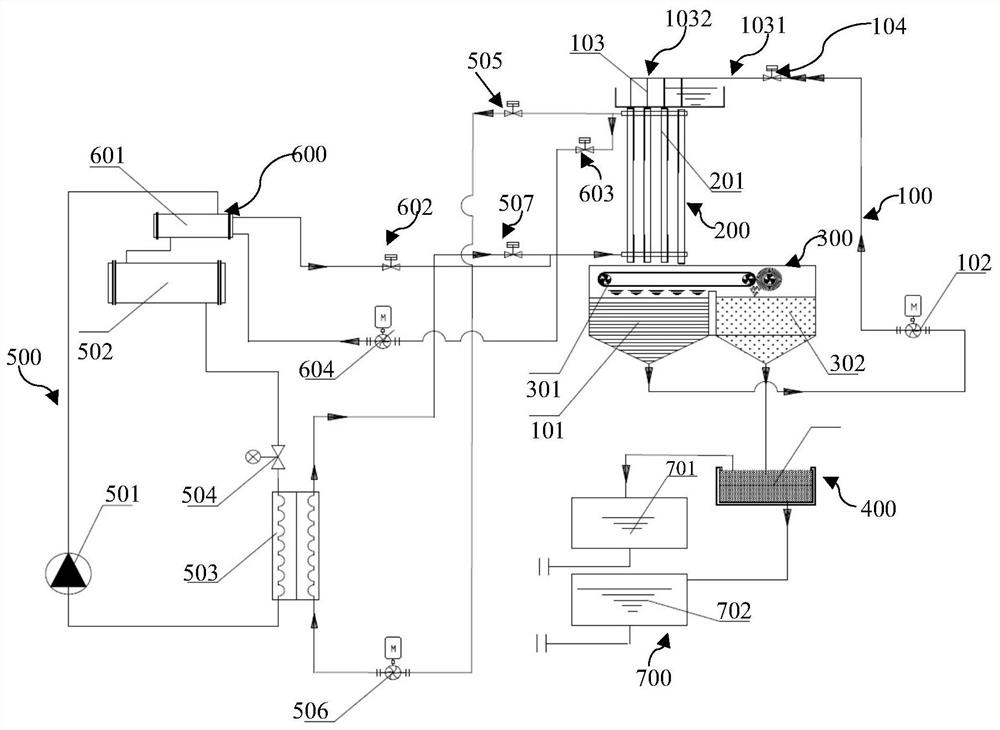

[0022] Embodiment 1: as figure 1 As shown, a high-salt wastewater freeze concentration separation treatment device of the present invention includes a high-salt wastewater circulation system 100, a freezing system 200 for treating high-salt wastewater, a crushing system 300 for crushing the product of the freezing system 200, The separation system 400 for the solid-liquid separation of the product sent out by the crushing system 300, the refrigeration system 500 for the refrigeration of the freezing system 200, and the frosting system 600 for the frosting of the freezing system 200; the refrigeration system 500 includes a compressor 501, and The condenser 502 communicated with the compressor 501, the evaporator 503 communicated with the refrigerant outlet of the condenser 502, and the expansion valve 504 arranged between the condenser 502 and the evaporator 503; the brine inlet of the freezing system 200 and the evaporator The brine outlet of 503 is connected, and the brine ou...

Embodiment 2

[0028] Embodiment 2: Utilize the high-salt wastewater freeze concentration separation treatment device of embodiment 1 to carry out high-salt wastewater treatment, the treatment steps are as follows: include the following steps:

[0029] Step 1: The high-salt wastewater is sent to the freezing system 200, and the high-salt wastewater is frozen in the freezing system 200 to realize preliminary separation of brine, and the unfrozen high-salt wastewater sent to the freezing system 200 is circulated through the high-salt wastewater The system 100 is sent to the freezing system 200 again, and the refrigeration system 500 maintains the cold field of the freezing system 200 through the circulation of the brine.

[0030] Step 2: Turn off the refrigeration system 500, turn on the frost-holding system 600, defrost and defrost the ice in the icing system 200, and the products sent from the icing system 200 are crushed by the crushing system 300, and the crushed products are sent to The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com