Intensive ecological treatment equipment for village and town sewage

An ecological treatment and intensive technology, applied in the direction of degassed water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of shortened distance, insufficient contact between biogas and air, and biogas volatilization Incomplete and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

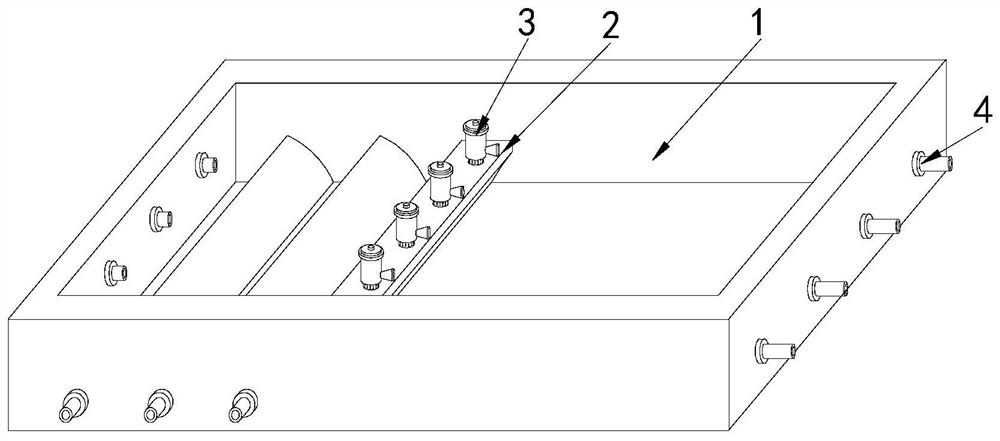

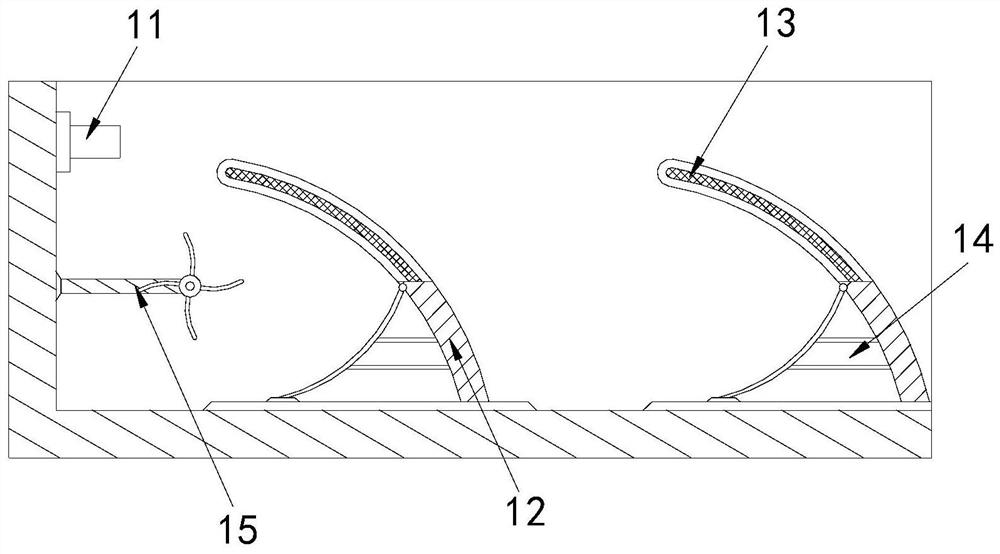

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

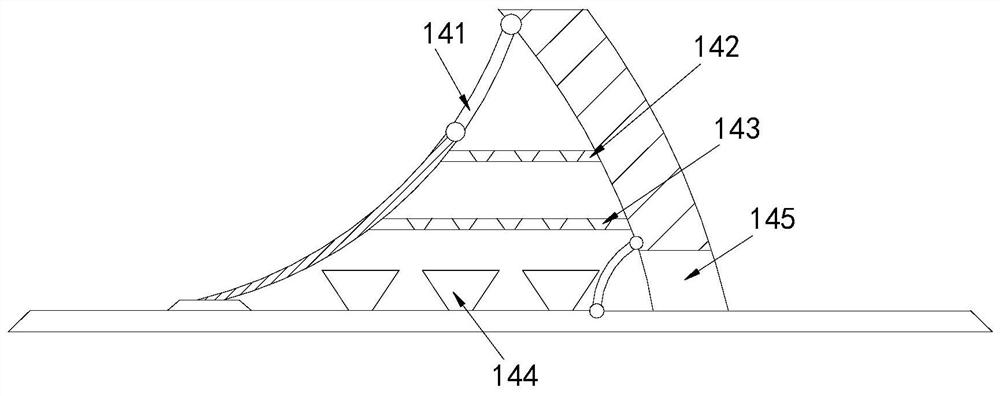

[0027] Its structure includes an aeration tank 1, a support plate 2, an aerator 3, and a drain 4. A support plate 2 is provided in the middle of the aeration tank 1, and the support plate 2 is installed horizontally. The aeration There are four machines 3, and they are arranged horizontally on the upper end of the support plate 2. The outlet 4 is located at the rear end of the aeration tank 1. The aeration tank 1 includes a water inlet 11, a dirt retaining plate 12, and a filter screen 13. , collecting device 14, crushing device 15, described water inlet 11 is arranged on the front end of aeration tank 1, described dirt baffle 12 is provided with two, and is positioned at the inner front end of aeration tank 1, and described filter screen 13 is embedded and fixed on the top of the dirt baffle 12, the collection device 14 is arranged at the bottom front en...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033] The crushing device 15 includes a rotating shaft b1, a rotating plate b2, a crushed material net b3, and a guide block b4. The side end of the rotating shaft b1 is provided with a rotating plate b2. There are four rotating plates b2, which surround the rotating shaft arranged in b1, the crushed material net b3 is installed inside the rotating plate b2, the two ends of the guide block b4 are connected to the crushed material net b3, and the middle of the guide block b4 is bent to both ends, which is beneficial to flow water to both ends The scrap net b3 is guided.

[0034] The guide block b4 includes a water hole b41, a feed port b42, and a crushing net b43. There are seven water holes b41 arranged horizontally inside the guide block b4. On the top of the water hole b41, the crushing net b43 is embedded in the bottom of the guide block b4, and the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com