Phase-change temperature-regulating asphalt and preparation method thereof

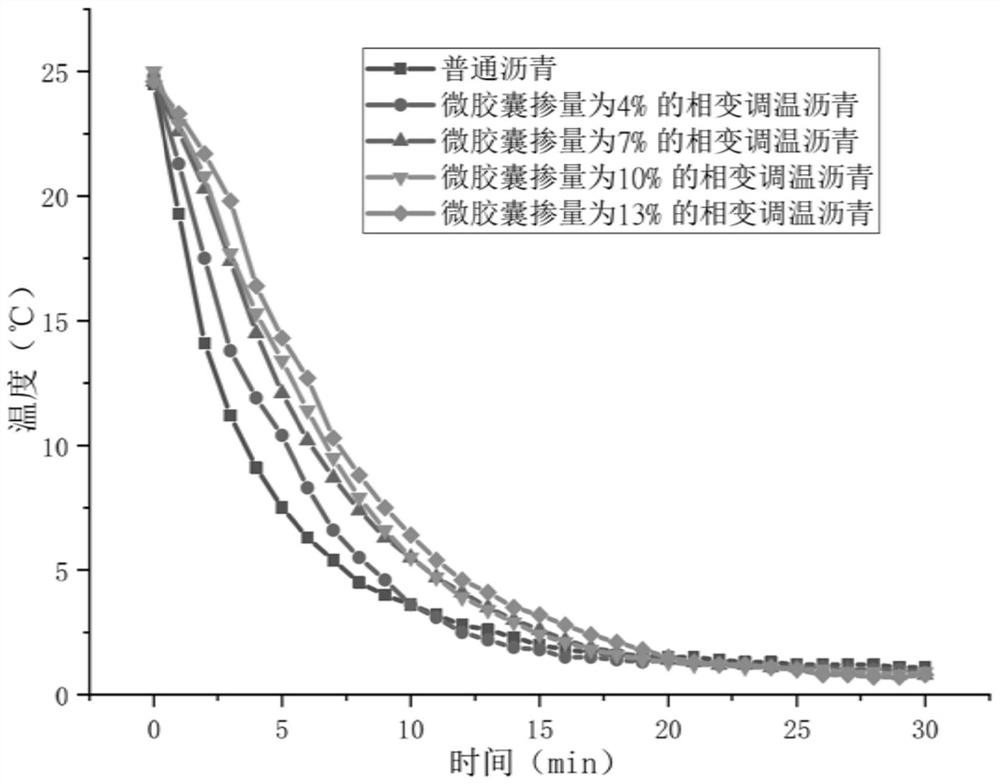

A kind of asphalt and phase change technology, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of poor anti-slip and crack resistance, improve low-temperature performance, delay the cooling rate, shorten the occurrence and duration of Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

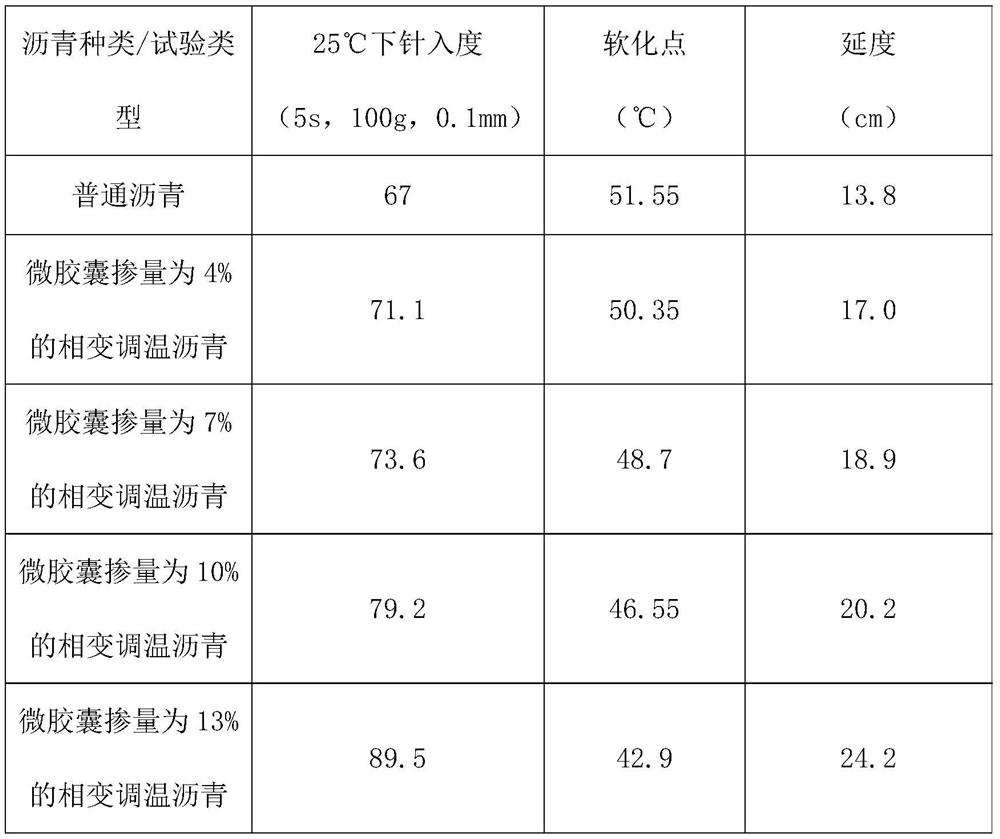

Embodiment 1

[0047] Preparation of phase-change temperature-adjusted asphalt with a dosage of 4%: heat the asphalt in an oven at 140°C, pour it into an aluminum pot and weigh the mass when the asphalt becomes liquid, put the aluminum pot into the heating jacket, and The temperature measuring probe matched with the heating jacket extends into the asphalt to ensure the temperature control of the asphalt during the shearing process. According to the bitumen quality that weighs, convert the quality of required tetradecane-n-octanoic acid phase-change microcapsules, then slowly add the tetradecane-n-octanoic acid phase-change microcapsules into the bitumen in stages, during which The glass rod was manually stirred slowly until the tetradecane-n-octanoic acid phase change microcapsules were submerged in the asphalt, and the phase change temperature regulating asphalt was prepared.

[0048] Insert the rotor of the high-speed shearing machine into the asphalt, adjust the height of the rod connecti...

Embodiment 2

[0050] Preparation of phase-change temperature-adjusted asphalt with a dosage of 7%: heat the asphalt in an oven at 140°C, pour it into an aluminum pot when the asphalt becomes liquid and weigh it, put the aluminum pot into the heating jacket, and The temperature measuring probe matched with the heating jacket extends into the asphalt to ensure the temperature control of the asphalt during the shearing process. According to the bitumen quality that weighs, convert the quality of required tetradecane-n-octanoic acid phase-change microcapsules, then slowly add the tetradecane-n-octanoic acid phase-change microcapsules into the bitumen in stages, during which Slowly stir manually with a glass rod until the tetradecane-n-octanoic acid phase change microcapsules are submerged in the asphalt.

[0051] Insert the rotor of the high-speed shearing machine into the asphalt, adjust the height of the rod connecting the rotor so that the distance between the rotor and the bottom of the pot...

Embodiment 3

[0053] Preparation of phase-change temperature-adjusted asphalt with a dosage of 10%: heat the asphalt in an oven at 140°C, pour it into an aluminum pot and weigh the mass when the asphalt becomes liquid and flowy, put the aluminum pot into the heating jacket, and The temperature measuring probe matched with the heating jacket extends into the asphalt to ensure the temperature control of the asphalt during the shearing process. According to the bitumen quality that weighs, convert the quality of required tetradecane-n-octanoic acid phase-change microcapsules, then slowly add the tetradecane-n-octanoic acid phase-change microcapsules into the bitumen in stages, during which Slowly stir manually with a glass rod until the tetradecane-n-octanoic acid phase change microcapsules are submerged in the asphalt.

[0054] Insert the rotor of the high-speed shearing machine into the asphalt, adjust the height of the rod connecting the rotor so that the distance between the rotor and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com