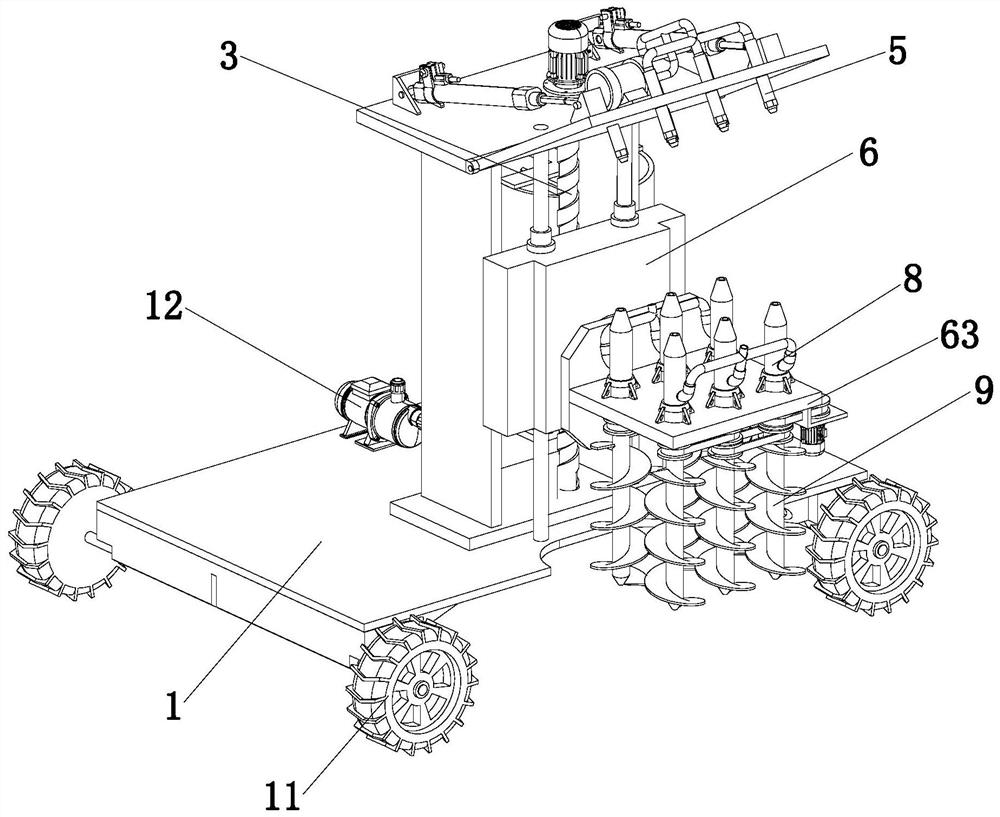

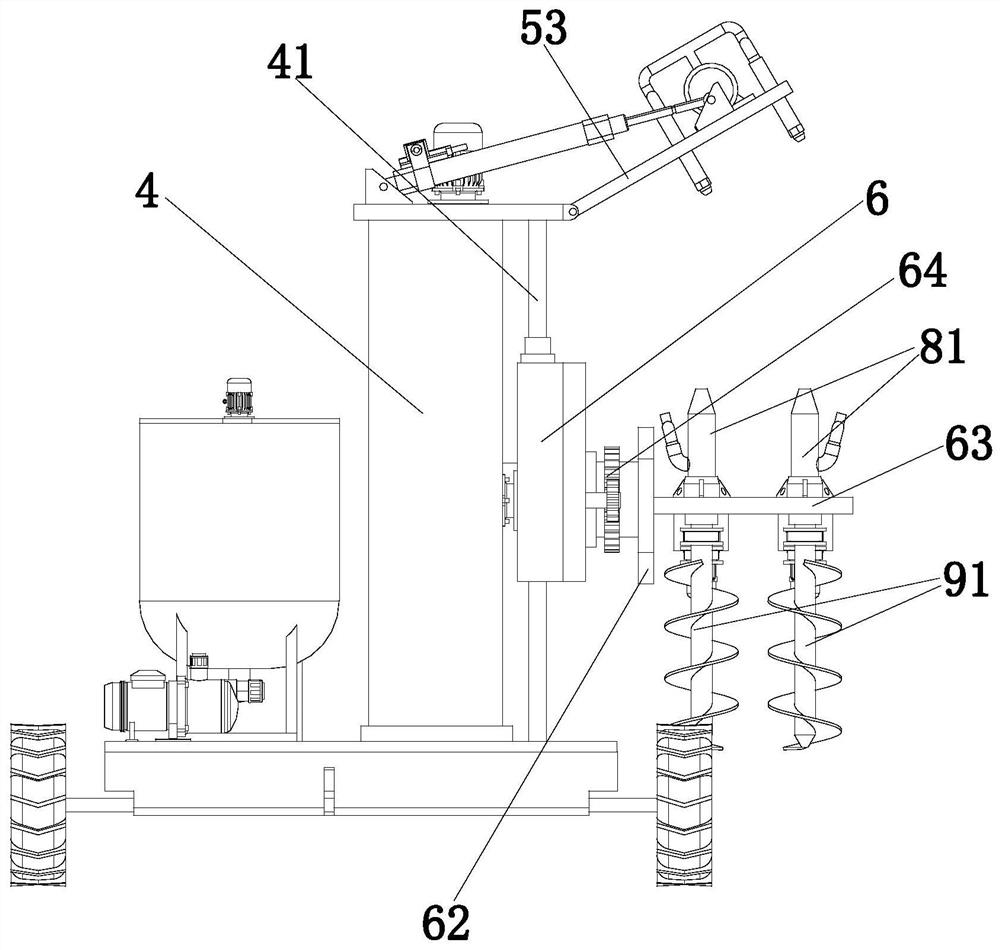

Automatic filling equipment for static blasting expanding agent

A technology of static blasting and expansion agent, which is applied in the direction of blasting, drilling equipment, drilling equipment and methods, etc., and can solve problems such as blockage and expansion agent dripping on the ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

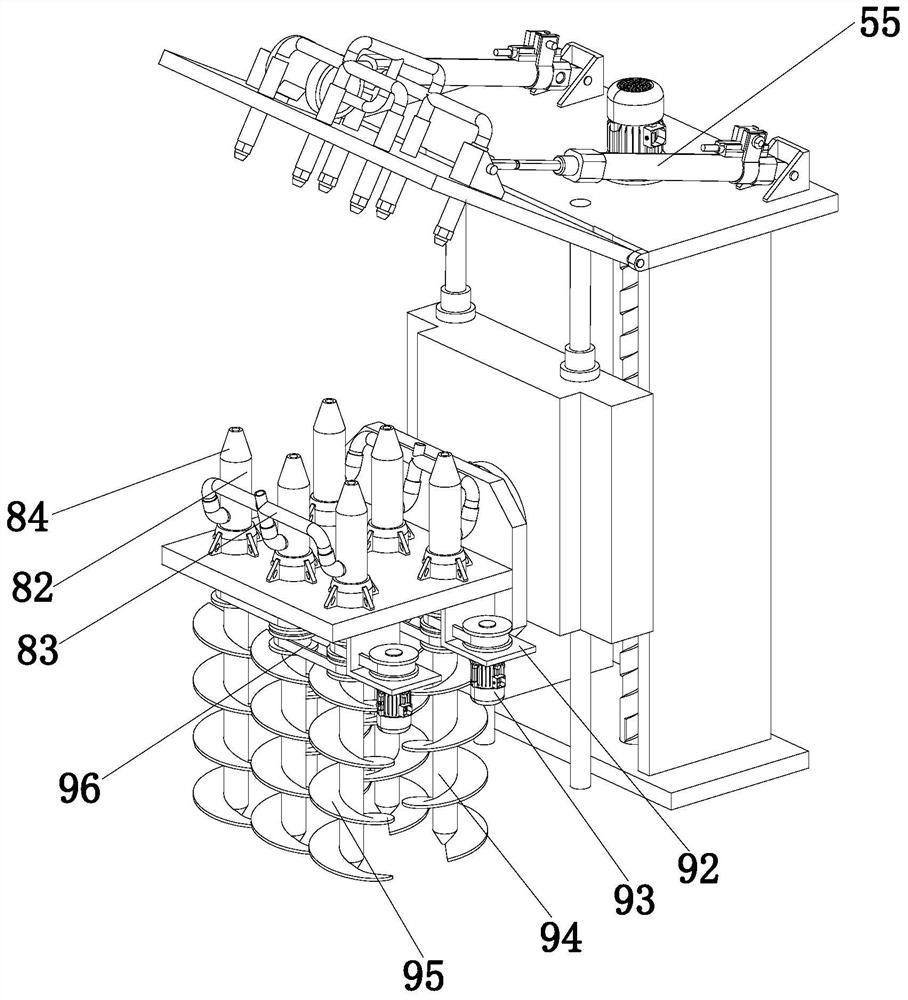

[0048] Based on the automatic filling device for static blasting expansion agent provided in the first embodiment of the present application, the second embodiment of the present application proposes another automatic filling device for static blasting expansion agent. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0049] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0050] The difference between the static blasting expansion agent automatic filling equipment provided by the second embodiment of the present application is that it also includes a pushing cylinder 7, a reversing motor 71, a horizontally arranged feed plate 72 and a feed plate 72 arranged on the feed plate 72. The bearing seat 73 at the top, the bearing seat 73 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com