Water film spreading device of solar cell wet etching machine

A technology of solar cells and wet etching, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve problems such as dust pollution, no design of water cycle design, and no reuse of water, so as to avoid waste, waste water, etc. The effect of fully pouring and saving liquid medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

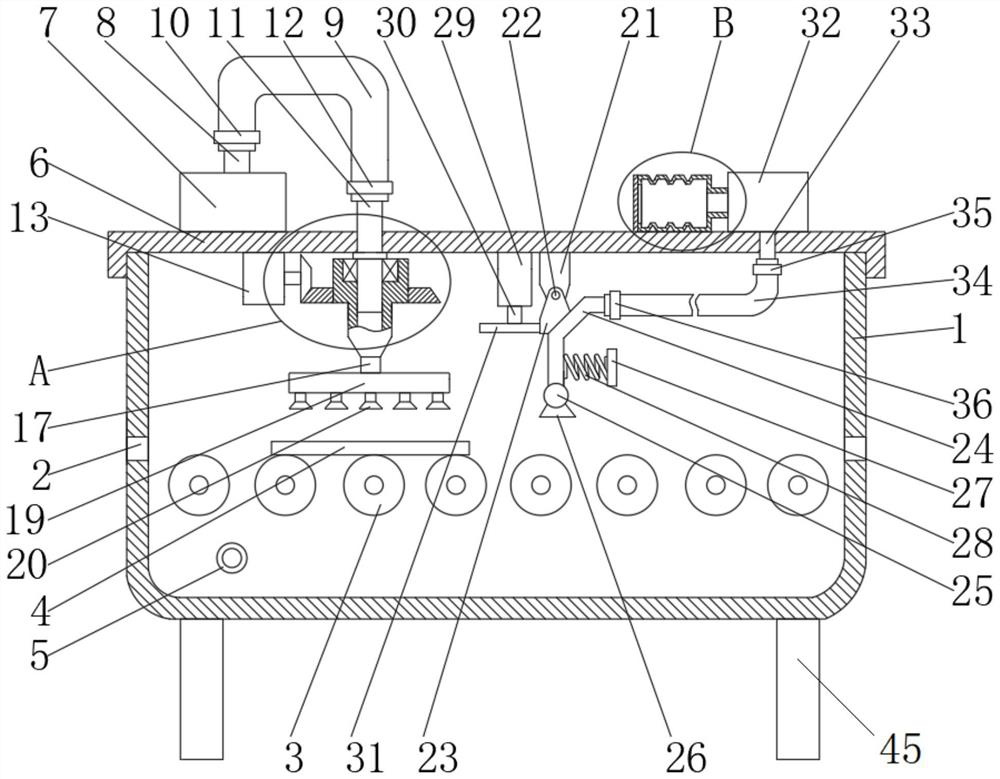

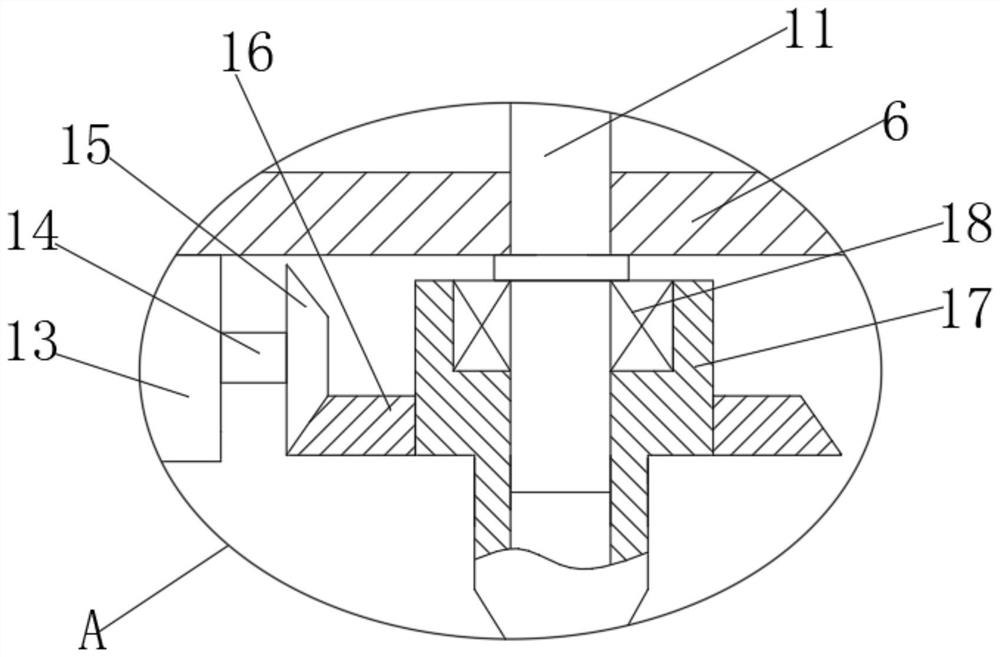

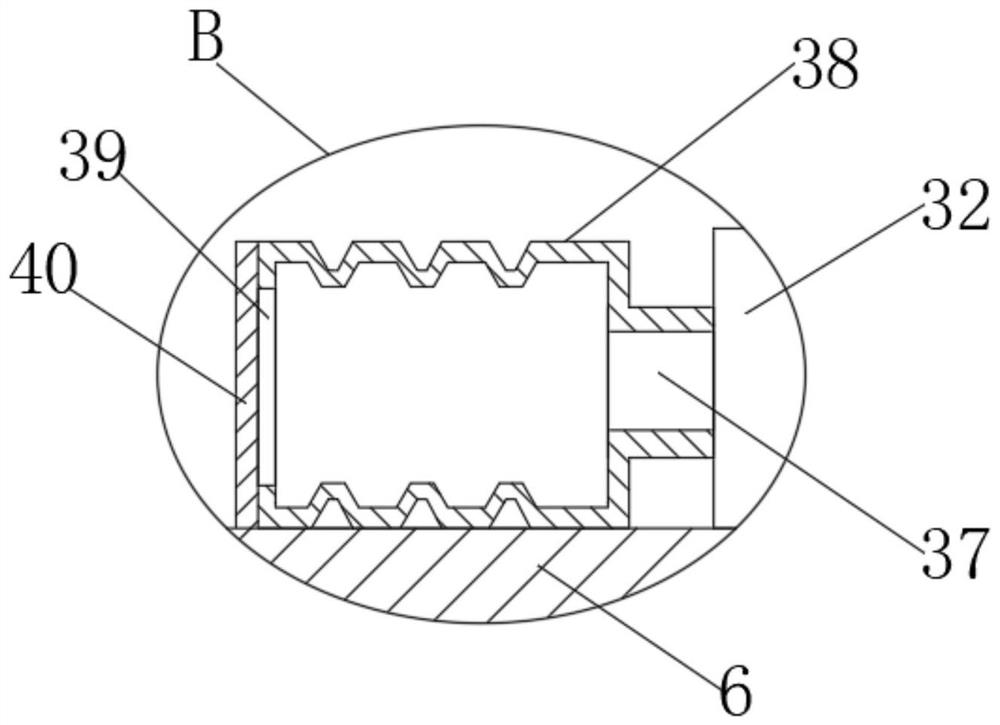

[0027] A water film spreading device for a solar cell wet etching machine, comprising an etching machine body 1, through grooves 2 are opened on the left and right sides of the etching machine body 1, and the etching machine body 1 is provided with There are a plurality of transmission rollers 3, and the plurality of transmission rollers 3 are arranged at equal intervals. Silicon wafers 4 are placed on the transmission rollers 3, and a water outlet pipe 5 is fixedly connected to the side wall of the etching machine body 1. The outer side of the water outlet pipe 5 is sleeved with a second water delivery hose 42, and the outer side of the connection between the second water delivery hose 42 and the water outlet pipe 5 is fixedly installed with a sixth clamp 44. The etching machine The upper end of the body 1 is engaged with the organic cover 6, and the upper end of the cover 6 is fixedly equipped with a water pump 7. The upper end of the water pump 7 is provided with a water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com