Solar cell, back electrode thereof and preparation method

A solar cell and back electrode technology, which is applied in the field of solar cells, can solve the problem that the bifacial rate of the carrier collection effect cannot meet the use requirements, etc., and achieve the effects of reducing the isolated collection blank area, improving the conversion efficiency, and improving the collection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

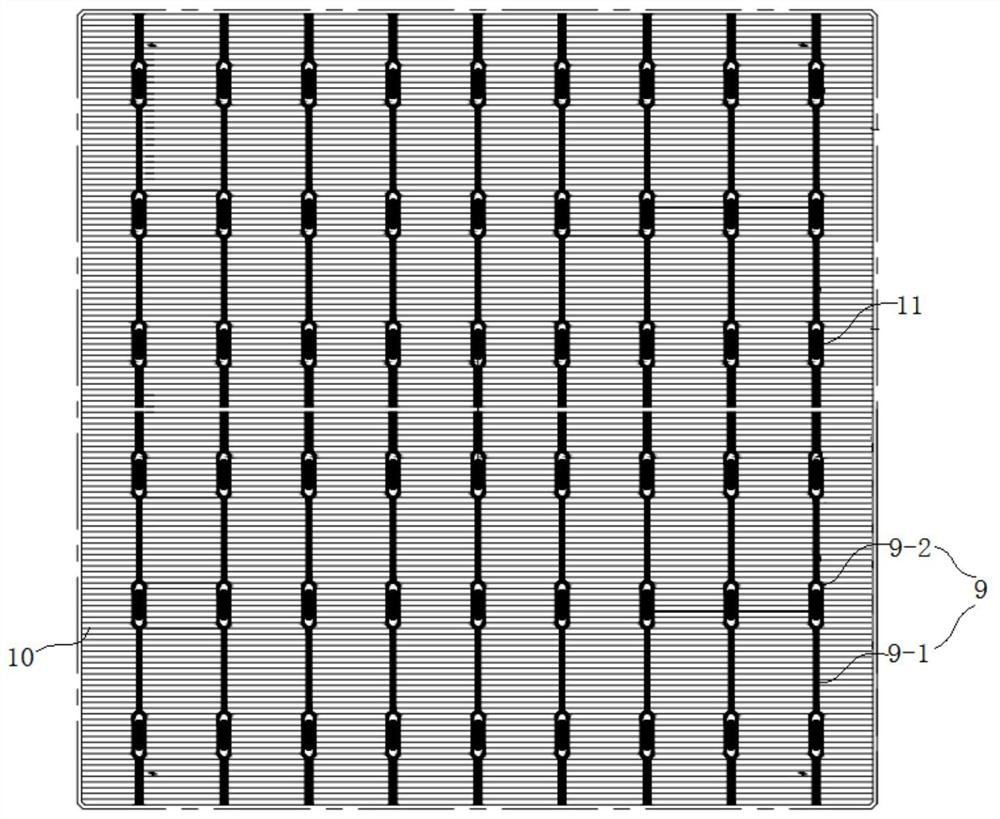

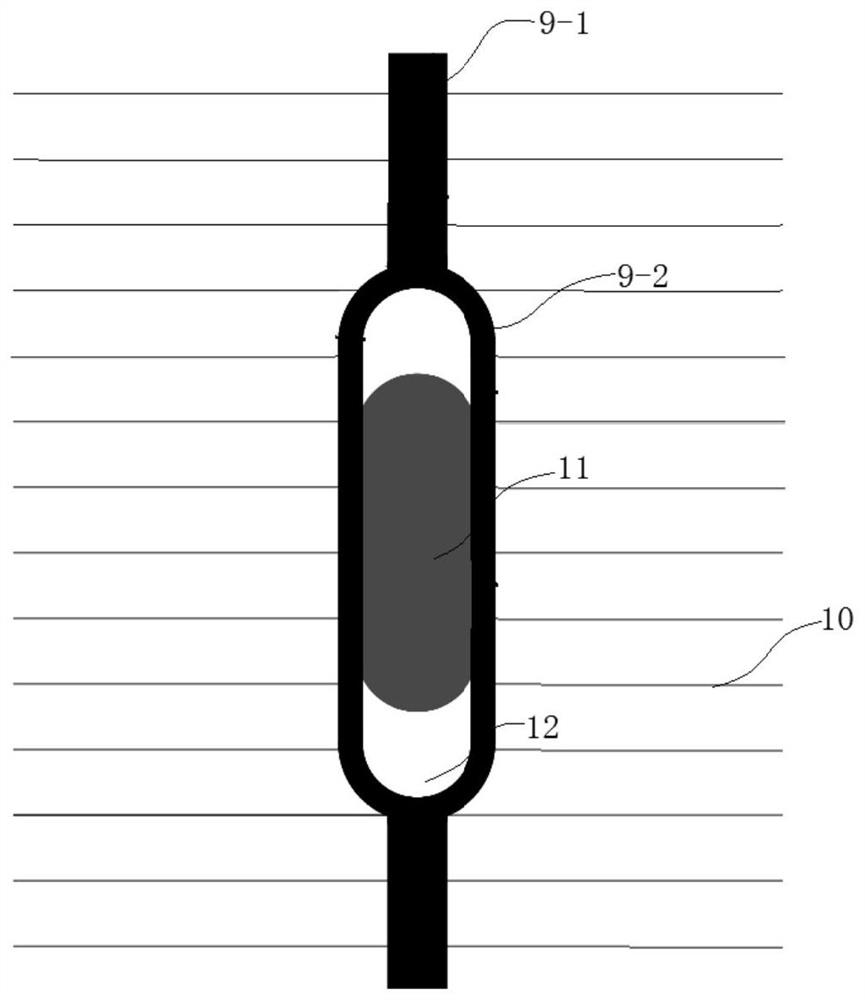

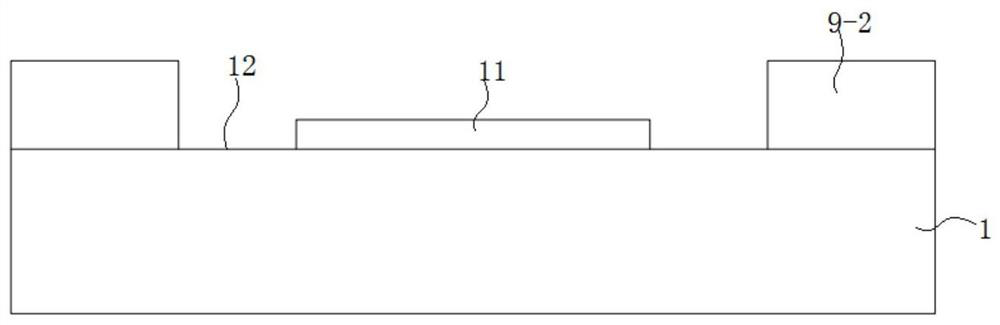

[0046] to combine Figure 4-Figure 6 , the back electrode of the solar cell of this embodiment includes an aluminum main grid 9, an aluminum sub-grid 10 and a back silver electrode 11, and the aluminum main grid 9 is composed of ring-shaped aluminum main grids 9-2 distributed at intervals and connecting adjacent rings The through-type aluminum main grid 9-1 is composed of the ring-shaped aluminum main grid 9-2, and the back silver electrode 11 is located inside the ring-shaped aluminum main grid 9-2 and is electrically connected to it. The through-type aluminum main grid 9-1 is directly connected to the aluminum main grid 9-1-1 from the central area and directly connected to the aluminum main grid 9-1-2 from the peripheral area located on the upper side of the central area directly above the aluminum main grid 9-1-1. Composition, the height of the back silver electrode 11 corresponds to the height of the central area directly connected to the aluminum main grid 9-1-1, and its ...

Embodiment 2

[0065] to combine Figure 4-Figure 6, the structure of the back electrode of the solar cell of the present embodiment is basically the same as that of the embodiment 1, and the main difference is that in the present embodiment, the number of segments of the back silver electrode 11 corresponding to the same aluminum busbar 9 is 10, and a single back electrode The width W1 of the silver electrode 11 is 2.0 mm, the length H1 is 3.0 mm, the internal length H2 of the ring-shaped aluminum busbar is 3.4 mm, and its internal width W2 is 1.8 mm. The inner width W4 of the peripheral area directly connected to the aluminum main grid 9-1-2 is 1.2 mm, and the width W3 of the central area directly connected to the aluminum main grid 9-1-1 is 1.3 mm. The number of the aluminum main grids 9 is 9, and the aluminum sub-grids 10 are perpendicular to the aluminum main grids 9 and are evenly spaced, and the width is 110 μm, and the spacing is 1.106 mm.

[0066] The manufacturing method of the ba...

Embodiment 3

[0069] to combine Figure 4-Figure 6 , the structure of the back electrode of the solar cell of the present embodiment is basically the same as that of the embodiment 1, and the main difference is that the number of segments of the back silver electrode 11 corresponding to the same aluminum busbar 9 in the present embodiment is 20, and a single back electrode The width W1 of the silver electrode 11 is 1.4 mm, the length H1 is 1.9 mm, the inner length H2 of the ring-shaped aluminum busbar is 2.2 mm, and the inner width W2 is 1.3 mm. The inner width W4 of the peripheral area directly connected to the aluminum main grid 9-1-2 is 1.0 mm, and the width W3 of the central area directly connected to the aluminum main grid 9-1-1 is 0.9 mm. The number of the aluminum main grids 9 is 12, and the aluminum sub-grids 10 are perpendicular to the aluminum main grids 9 and are evenly spaced, and the width is 80 μm, and the spacing is 1.0 mm.

[0070] The manufacturing method of the back elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com