a te x s y Co-doped micro-nano structure material, preparation method, battery electrode material sheet and lithium-sulfur battery

A micro-nano structure and battery electrode technology, applied in battery electrodes, structural parts, lithium batteries, etc., can solve the problems of further improvement of electrochemical performance, strict synthesis conditions, and difficulty in large-scale production, achieving huge application potential and industrial Value, excellent performance, effect of good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] S1: Weigh a certain amount of sodium hydroxide and sodium sulfide materials into a beaker, add an appropriate amount of deionized water to fully stir and dissolve, transfer the dissolved aqueous solution to a volumetric flask, and obtain a certain concentration of sulfur-containing hydrogen after constant volume Sodium oxide solution, stand for use, wherein the mass ratio of sodium sulfide material to sodium hydroxide is 12:1, and the concentration of sodium sulfide is 2.0mol L -1 ;

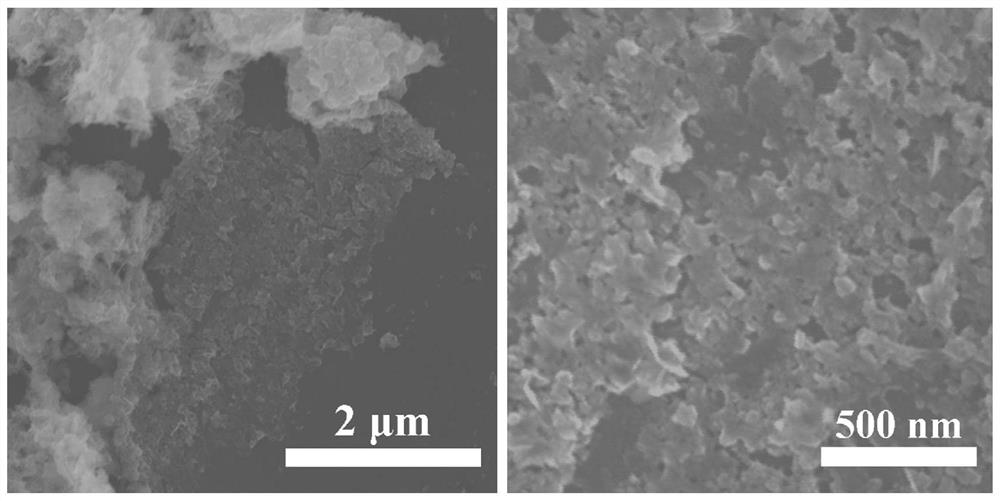

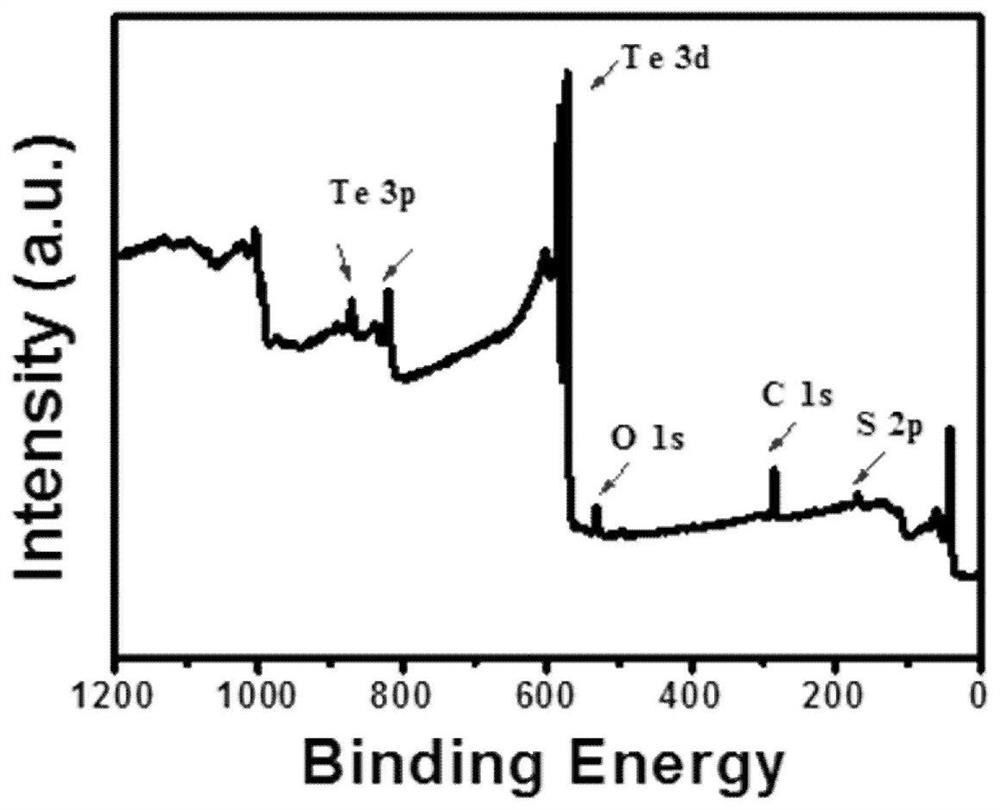

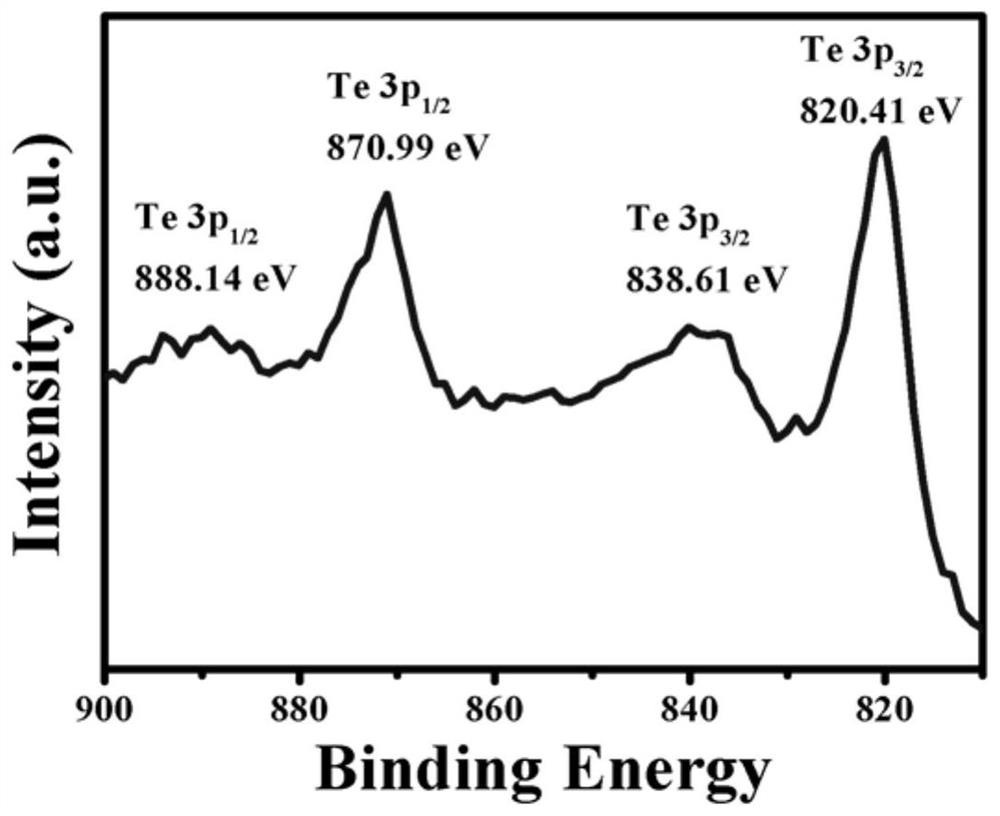

[0070] S2: Weigh a certain amount of tellurium, grind it into fine particles in an agate mortar, then use weighing paper to move the fine particles to the quartz tube, set the quartz tube to the vacuum packaging device, and slowly vacuum for 30 minutes to avoid the powder Splash inside the quartz tube. The quartz tube was burnt at high temperature with a hydrogen flame spray gun to make the caliber bonded, and the sample was vacuum-packed. After vacuum packaging, anneal at high temperatu...

Embodiment 2-3

[0072] Embodiment 2-3: the investigation of material consumption ratio in the step S1

[0073] Embodiment 2-3: except that in step S1, the mass ratio of sodium sulfide and sodium hydroxide is replaced by 6:1 and 18:1, other operations are all the same, thereby repeat operation embodiment 1, thus carried out successively In Example 2-3, the obtained tellurium-sulfur co-doped materials were named M2 and M3 in sequence.

[0074] The sulfur and the amount ratio of tellurium of the product that table 1 different material dosage ratios obtain

[0075]

Embodiment 4-5

[0076] Embodiment 4-5: the investigation of annealing temperature in the step S2

[0077] Except that the high-temperature annealing temperature in step S2 was replaced by 450°C to 400°C and 500°C respectively, other operations were unchanged, so that Example 1 was repeated to obtain Examples 4-5 in sequence, and the obtained tellurium-sulfur co-doped The heterogeneous materials are therefore named M4, M5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com