Intelligent control straw harvesting, screening and plate making system

An intelligent control and straw technology, which is applied in the direction of harvesters, cutters, flat products, etc., can solve the problems of low degree of automation, insufficient use of straw, poor reuse effect, etc., and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

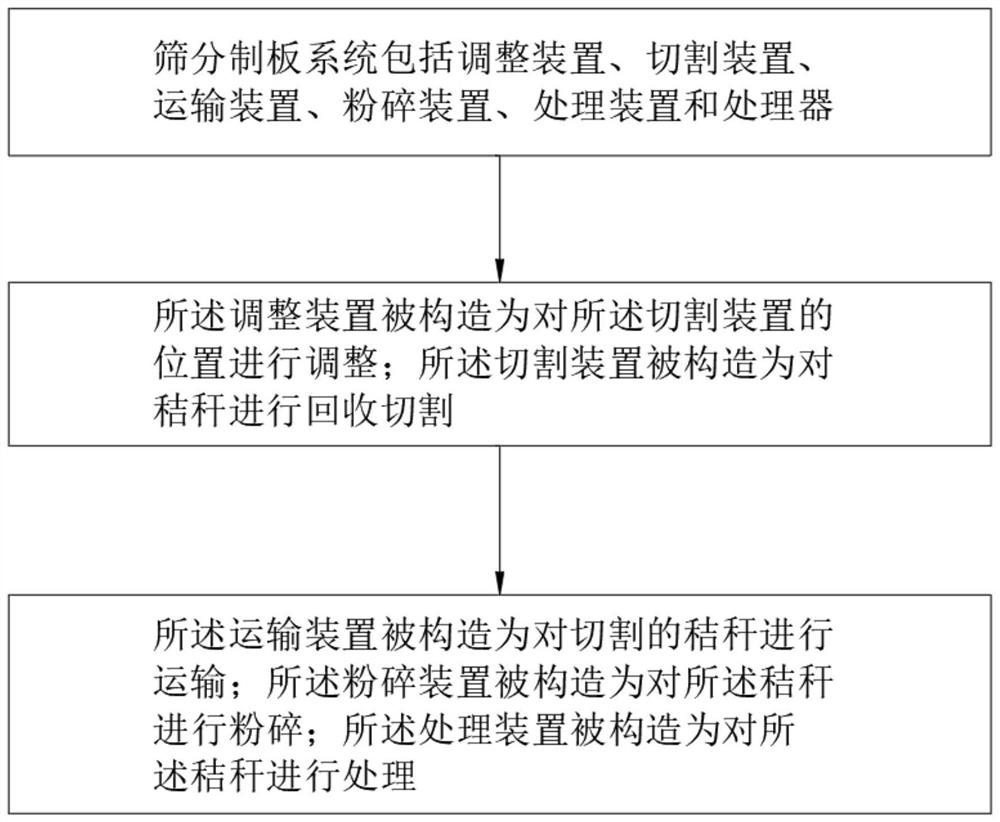

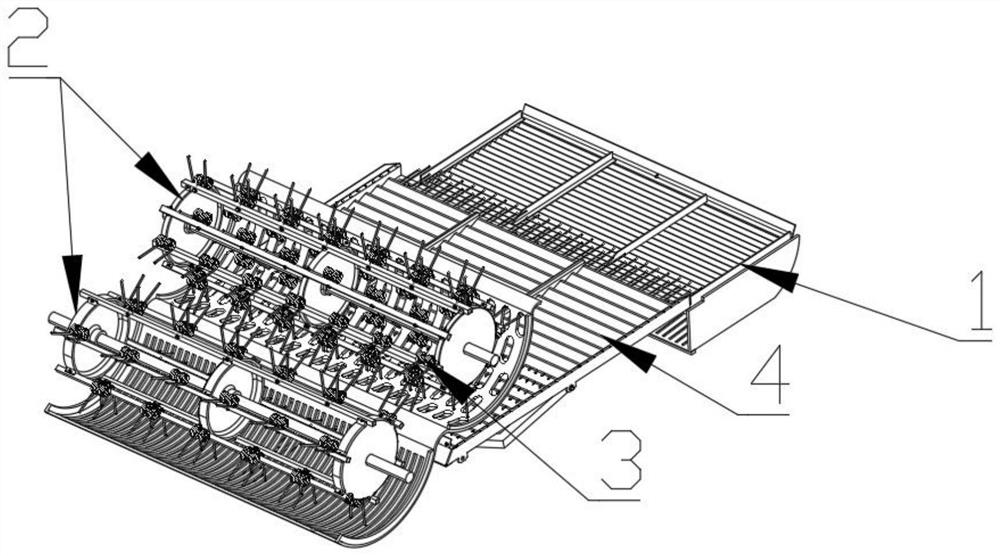

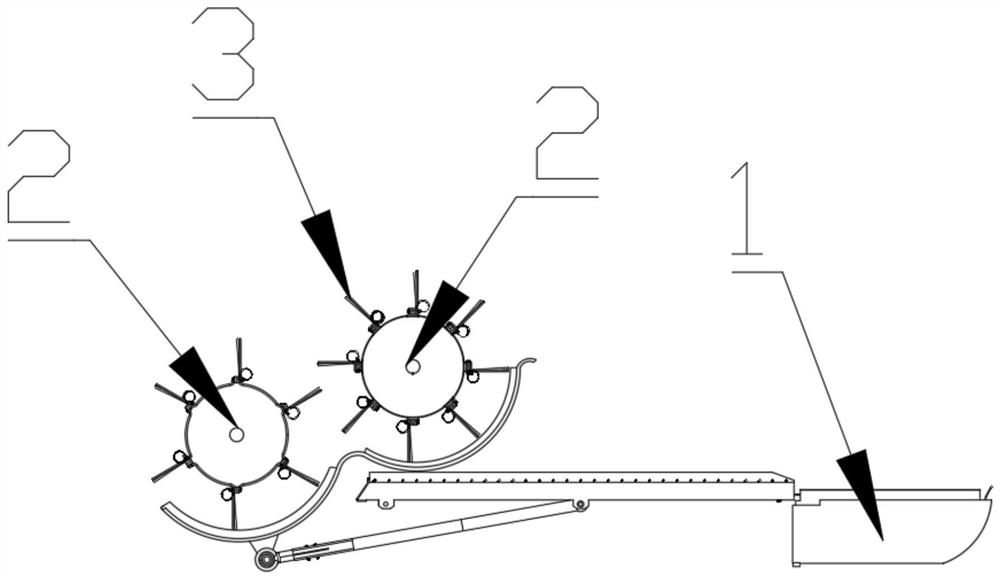

[0032] Embodiment 1: An intelligently controlled straw harvesting, screening and board-making system, the screening and board-making system includes an adjustment device, a cutting device, a transport device, a crushing device, a processing device and a processor, and the adjustment device is configured to The position of the cutting device is adjusted; the cutting device is configured to recycle and cut the straw; the transport device is configured to transport the cut straw; the crushing device is configured to crush the straw; The processing device is configured to process the straw;

[0033] Optionally, the adjustment device includes an adjustment rod, a recovery chamber, a filter screen and an adjustment drive mechanism, one end of the adjustment rod is drivingly connected to the adjustment drive mechanism, and the other end of the adjustment rod is connected to the adjustment drive mechanism The driving connection forms an adjustment part, and the adjustment part is conf...

Embodiment 2

[0038] Embodiment 2: Reasonable and effective utilization and development of biomass straw resources has great potential for energy saving and environmental protection. In today's increasingly severe energy and resources, turning waste into treasure and turning harm into profit, its economic and social benefits are even more irresistible. Underestimation; At the same time, there are common problems such as insufficient utilization of straw, poor reuse effect, low degree of automation and inability to collect automatically;

[0039] An intelligently controlled straw harvesting, screening and board-making system is provided, the screening and board-making system includes an adjustment device, a cutting device, a transport device, a crushing device, a processing device and a processor, and the adjustment device is configured to control the cutting device The position of the cutting device is adjusted; the cutting device is configured to recycle and cut the straw; the transport dev...

Embodiment 3

[0046] Embodiment 3: This embodiment should be understood as at least including all the features of any one of the foregoing embodiments, and further improvement on the basis of it; providing an intelligently controlled straw harvesting, screening, and board system, and a screening board system It includes an adjustment device, a cutting device, a transport device, a crushing device, a processing device and a processor, the adjustment device is configured to adjust the position of the cutting device; the cutting device is configured to recycle and cut straw; the The transportation device is configured to transport the cut straw; the crushing device is configured to crush the straw; the processing device is configured to process the straw; device, the cutting device, the transportation device, the crushing device and the processing device are controlled and connected, and based on the processing operation of the processor, the efficient operation of the entire system is realized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com