Washing equipment for processing of pickled tuber mustard

A technology for cleaning equipment and pickled mustard, which is applied in applications, filtration and separation, food processing, etc., can solve the problems of wasting water sources, etc., and achieve the effects of convenient operation, suitable for popularization and use, and removal of dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

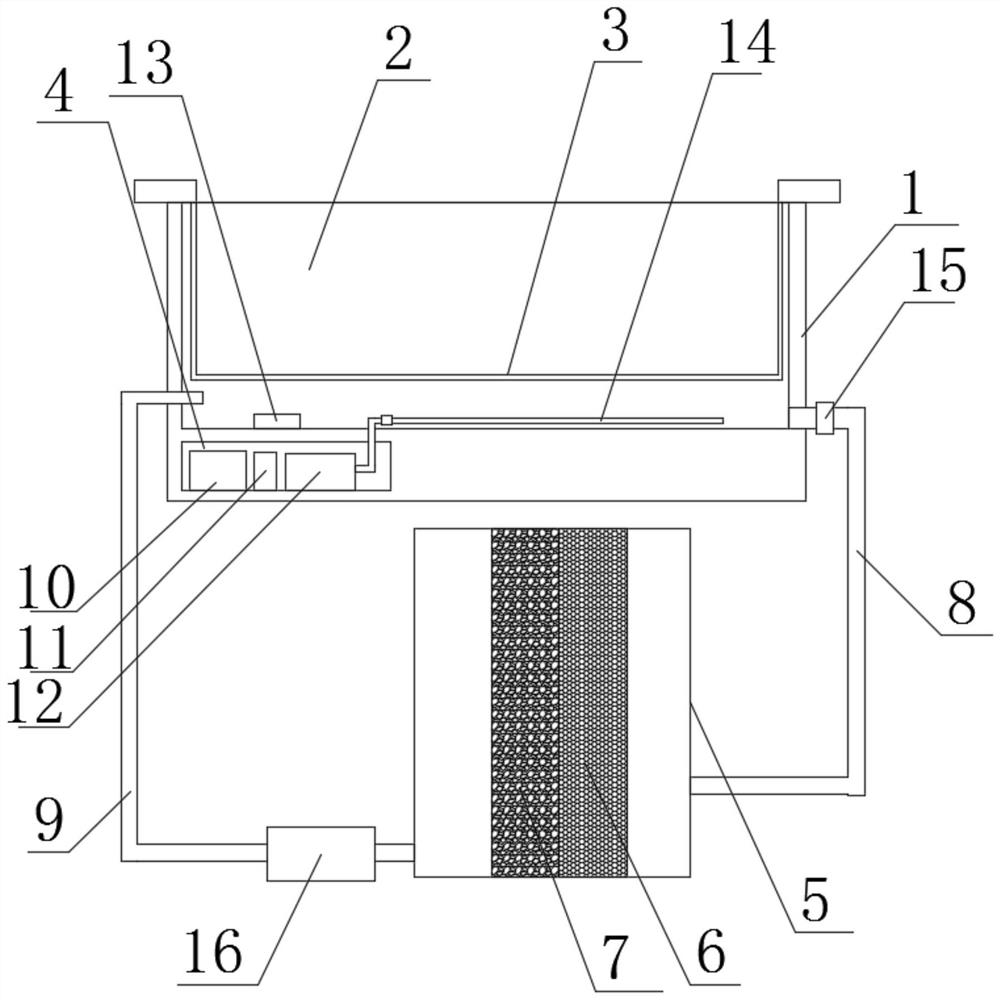

[0019] see figure 1 , this embodiment provides a technical solution:

[0020] A cleaning equipment structure for mustard processing, including a cleaning box 1 and a filter box 5. The inside of the cleaning box 1 is provided with a cleaning room 2 and a control room 4 sequentially from top to bottom. Above the cleaning room 2, there is a hole extending into the cleaning room 2. The stainless steel woven basket 3 is fixed with an array of transducers 13 on the bottom plate inside the cleaning room 2, and the air guide tube 14 is laid on the bottom plate inside the cleaning room 2. The air guide tube 14 is provided with an air outlet, and the right side of the bottom of the cleaning room 2 is set There is a water outlet pipe 8, and the inner center of the filter box 5 is fixedly arranged with activated carbon filter screen 7 and metal filter screen 6 sequentially from left to right. The return pipe 9 at the bottom of the cleaning chamber 2 is provided with a water pump 16, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com