Method for screening micro-nano powder

A micro-nano, powder technology, used in chemical instruments and methods, sieves, solid separation, etc., can solve difficult particle size fine sieving, impossible to achieve powder sieving, difficult to achieve medium and large particle sieves grading problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

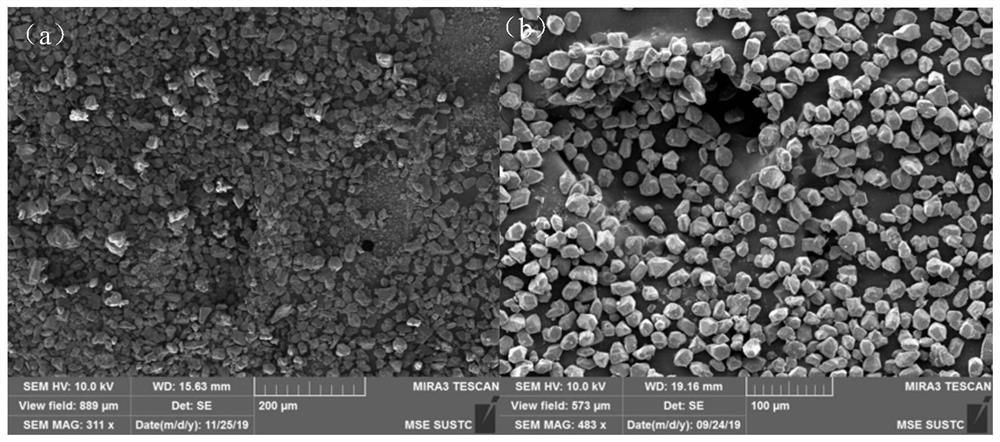

[0039] This embodiment provides a spherical alumina finely screened powder, which is prepared according to the following steps:

[0040] (1) Add 50g D50=15μm spherical alumina into 300g water, and disperse for 1min with an ultrasonic disperser to obtain a suspension;

[0041] (2) The suspension obtained in step (1) is gradually added to a metal sieve cylinder with a diameter of 10cm and a height of 10cm. The aperture of the screen at the bottom of the metal sieve cylinder is 20 μm, and the frequency of the application is 20K, ultrasonic waves with a power of 500W, and the ultrasound is classified to All the suspension passes through the sieve to the receiving container;

[0042] (3) vacuum filter the suspension obtained in step (2) until only powder particles remain;

[0043] (4) Put the powder particles obtained in step (3) into an oven and heat at 100° C. for 30 minutes to obtain a finely screened powder.

Embodiment 2

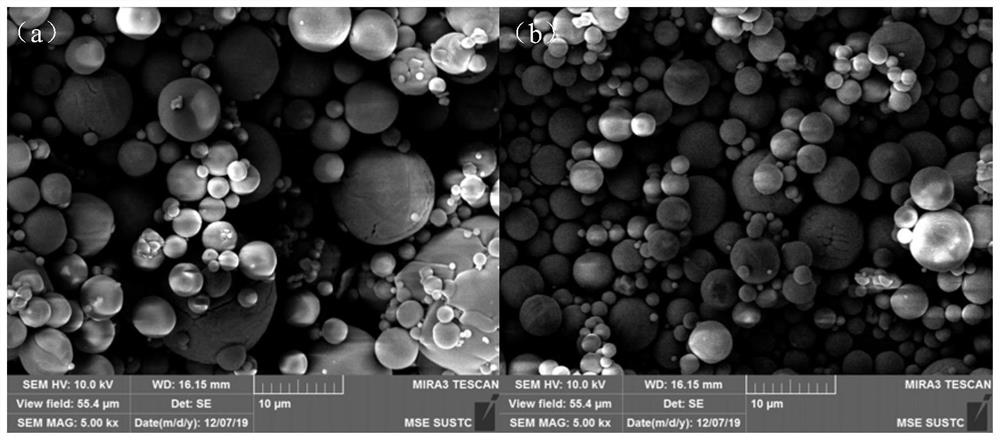

[0045] This embodiment provides a spherical alumina finely screened powder, which is prepared according to the following steps:

[0046] (1) Add 50g D50=5μm spherical alumina to 300g ethanol, and disperse for 1min with an ultrasonic disperser to obtain a suspension;

[0047] (2) The suspension obtained in step (1) is gradually added to a metal sieve cylinder with a diameter of 15 cm and a height of 15 cm. The aperture of the screen at the bottom of the metal sieve cylinder is 10 μm, and the applied frequency is 20K and ultrasonic waves with a power of 500W. Ultrasonic classification to All the suspension passes through the sieve to the receiving container;

[0048] (3) vacuum filter the suspension obtained in step (2) until only powder particles remain;

[0049] (4) Put the powder particles obtained in step (3) into an oven and heat at 80° C. for 30 minutes to obtain a finely screened powder.

Embodiment 3

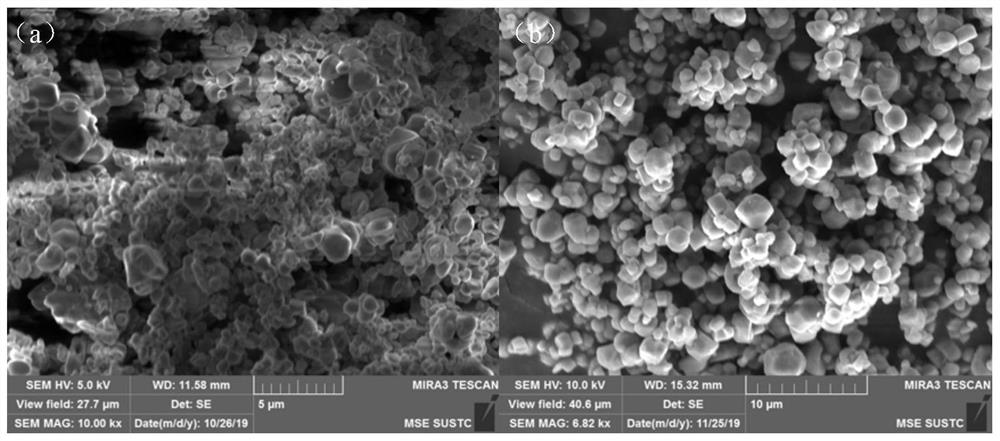

[0051] This embodiment provides a spherical alumina finely screened powder, which is prepared according to the following steps:

[0052] (1) Add 50g D50=3μm spherical alumina into 500g cyclohexane, and disperse for 1min with an ultrasonic disperser to obtain a suspension;

[0053] (2) The suspension obtained in step (1) is gradually added to a metal sieve cylinder with a diameter of 20 cm and a height of 20 cm. The aperture of the screen at the bottom of the metal sieve cylinder is 5 μm. The frequency of the application is 20K and the power is 500W. All the turbid liquid reaches the receiving container through the screen;

[0054] (3) vacuum filter the suspension obtained in step (2) until only powder particles remain;

[0055] (4) Put the powder particles obtained in step (3) into an oven and heat at 80° C. for 30 minutes to obtain a finely screened powder.

[0056] Effect comparison example

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com