A carbon rod discharge screening device

A discharge sieve and carbon rod technology, which is applied in sorting and other directions, can solve the problems of general and carbon rod damage to the screening effect, and achieve the effect of convenient operation, high screening efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

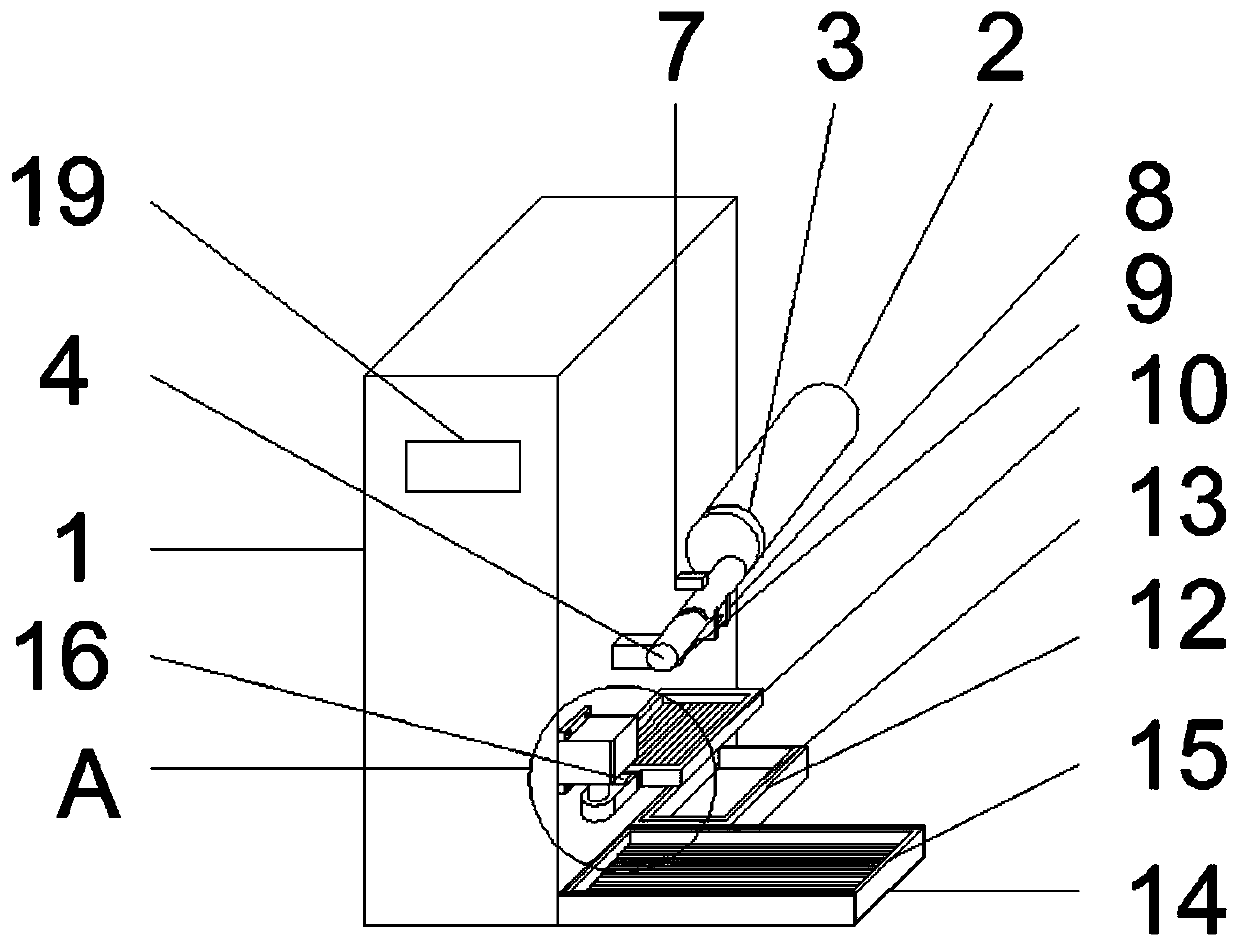

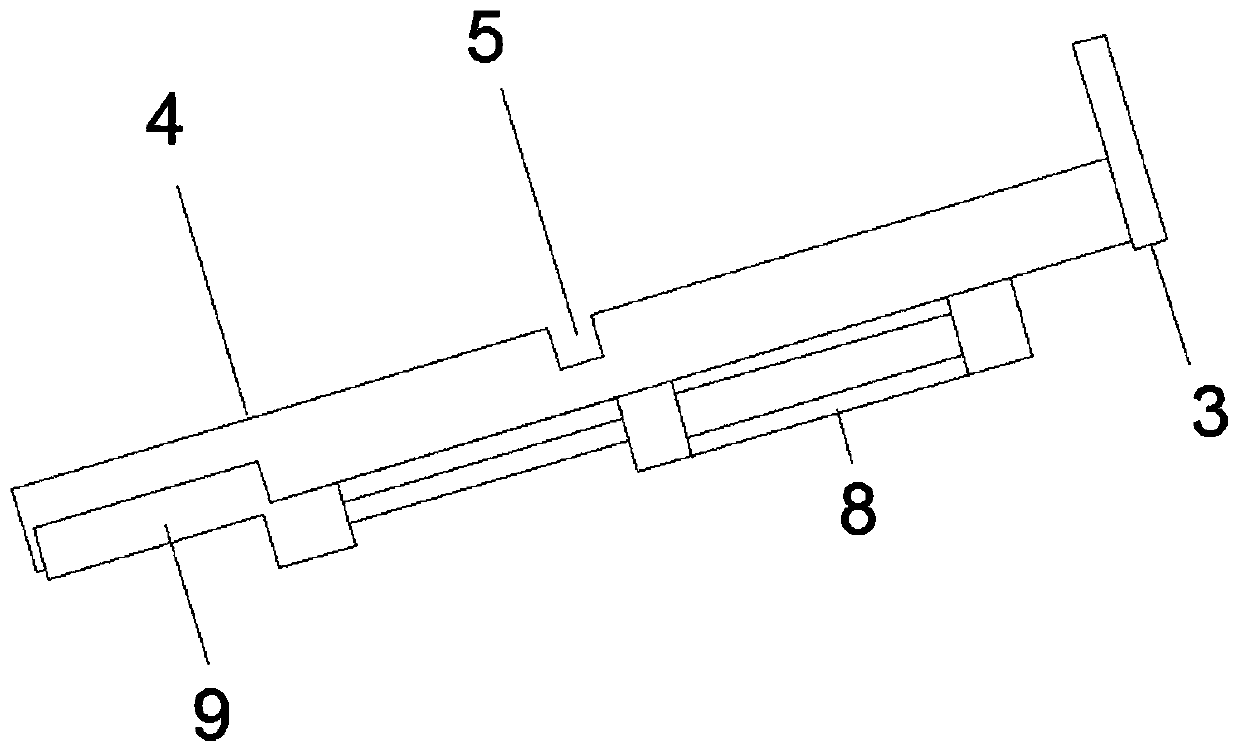

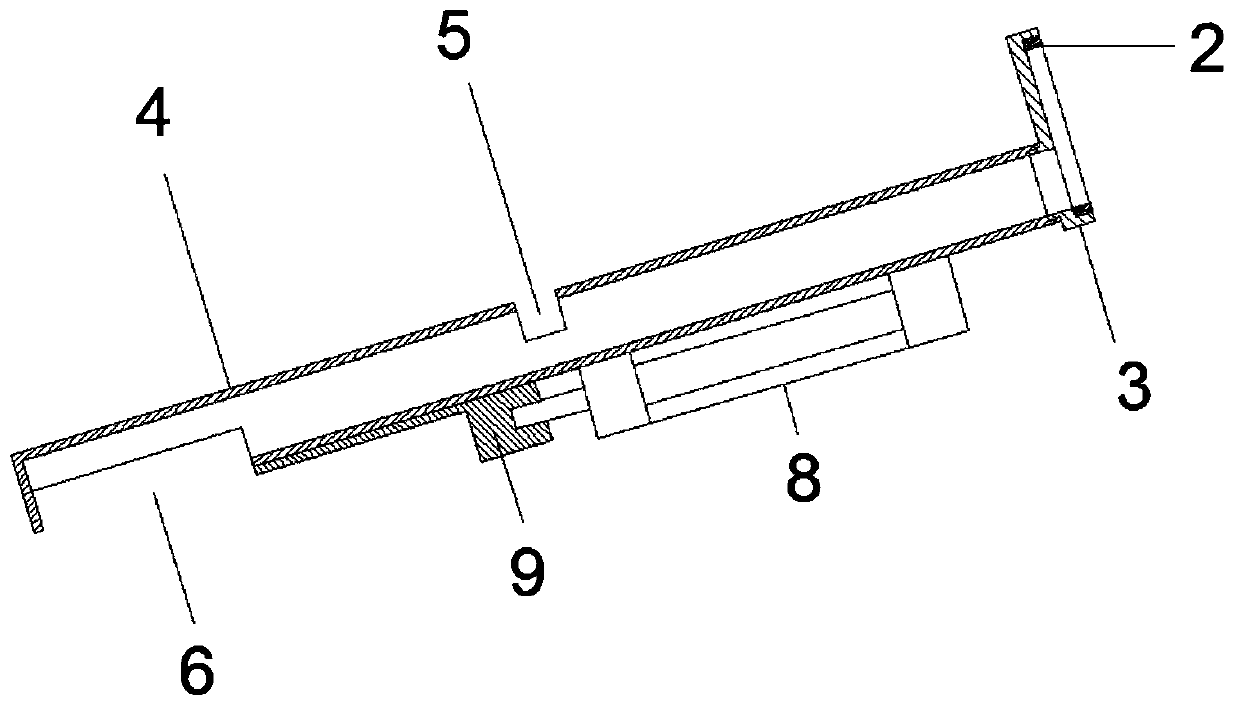

[0021] like Figure 1 to Figure 5 As shown, a carbon rod discharge screening device includes a support 1 and a controller 19 arranged on the support 1. The side of the support 1 is provided with a feed drum 2, a waste tank 12, a genuine product tank 14 and Photoelectric switch 7, the output end of described feed roller 2 is connected with roller cover 3, and described roller cover 3 is connected with guide tube 4, and the upper end of described guide tube 4 is provided with opening-5, and the lower end of described guide tube 4 Opening two 6 is provided, and described photoelectric switch 7 is located at the top of opening one 5, and the sidewall of described guide pipe 4 is provided with cylinder 8, and the piston rod of described cylinder 8 is connected with baffle plate 9, and described opening two 6 is provided with a material delivery frame 10 below, the side of the support 1 is provided with a first servo motor 11, the output shaft of the first servo motor 11 is connecte...

Embodiment 2

[0024] like Figure 1 to Figure 5 As shown, a carbon rod discharge screening device includes a support 1 and a controller 19 arranged on the support 1. The side of the support 1 is provided with a feed drum 2, a waste tank 12, a genuine product tank 14 and Photoelectric switch 7, the output end of described feed roller 2 is connected with roller cover 3, and described roller cover 3 is connected with guide tube 4, and the upper end of described guide tube 4 is provided with opening-5, and the lower end of described guide tube 4 Opening two 6 is provided, and described photoelectric switch 7 is located at the top of opening one 5, and the sidewall of described guide pipe 4 is provided with cylinder 8, and the piston rod of described cylinder 8 is connected with baffle plate 9, and described opening two 6 is provided with a material delivery frame 10 below, the side of the support 1 is provided with a first servo motor 11, the output shaft of the first servo motor 11 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com